My poor oven has been used to test every steam option known to me. Since my memory is not great my findings will be posted here, both for myself and any others that may be interested.

At present a Pressure Cooker is used to inject steam into the oven. It produces huge amounts of steam, but my breads still lack sheen and large blisters. The saga continues...

4/7/2021

The latest focus towards improvement is directed towards wet steam vs. dry steam. In an attempt to create wet steam the basic 15 pound Pressure Cooker (PC) regulator was changed to 5, 10, or 15 pounds. Today 2 test were performed with data logs made for each. The following links will take you to an interactive chart for each bake. Play with chart to learn various information. For example, clicking on a blue dot will open a note(s) for that particular time. Images may also be available.

Test #1

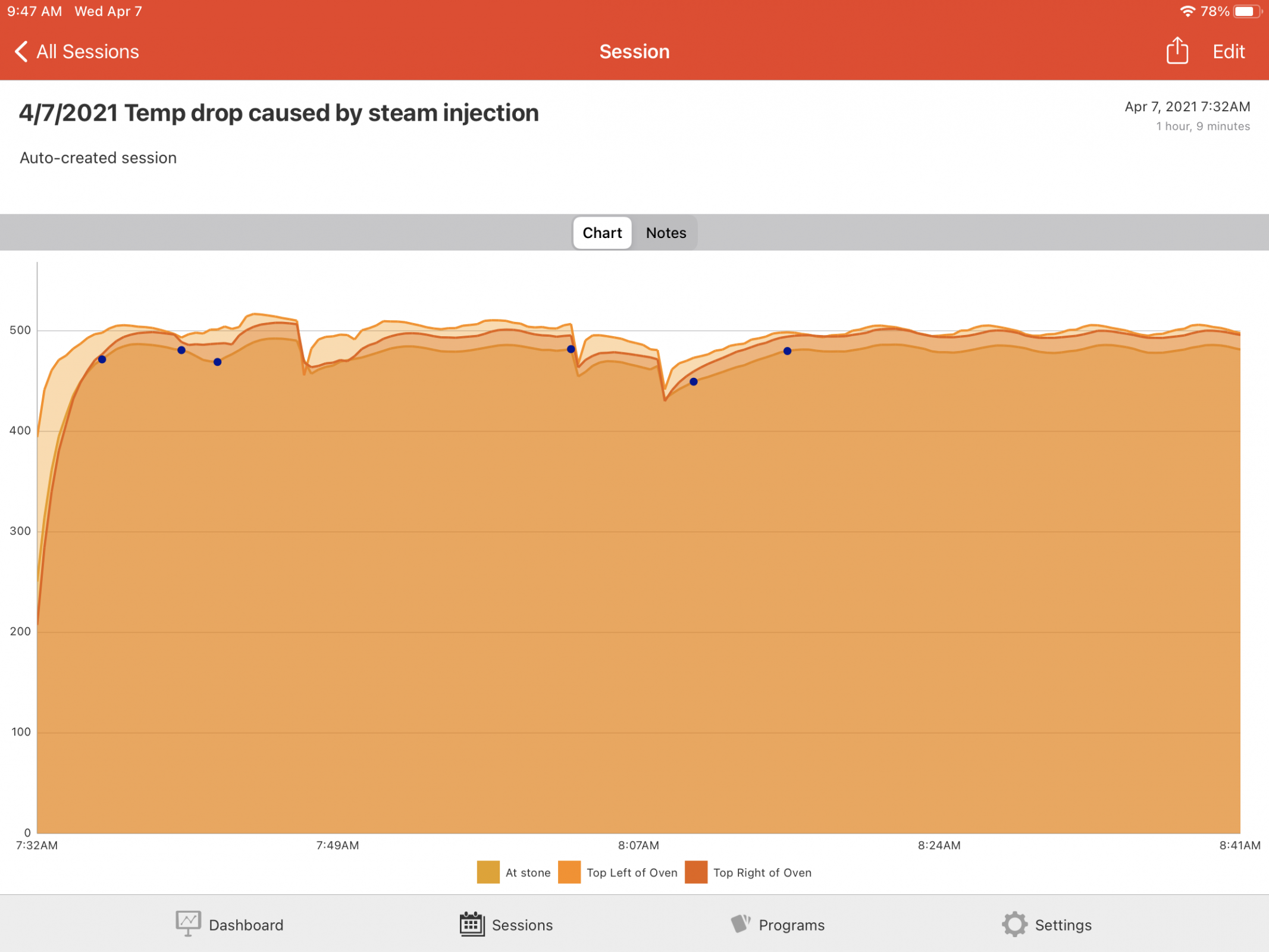

4/7/2021 Temp drop caused by steam injection. Steam was injected for 90 seconds @ 5# of pressure.

https://share.fireboard.io/78B6FC

Test #2

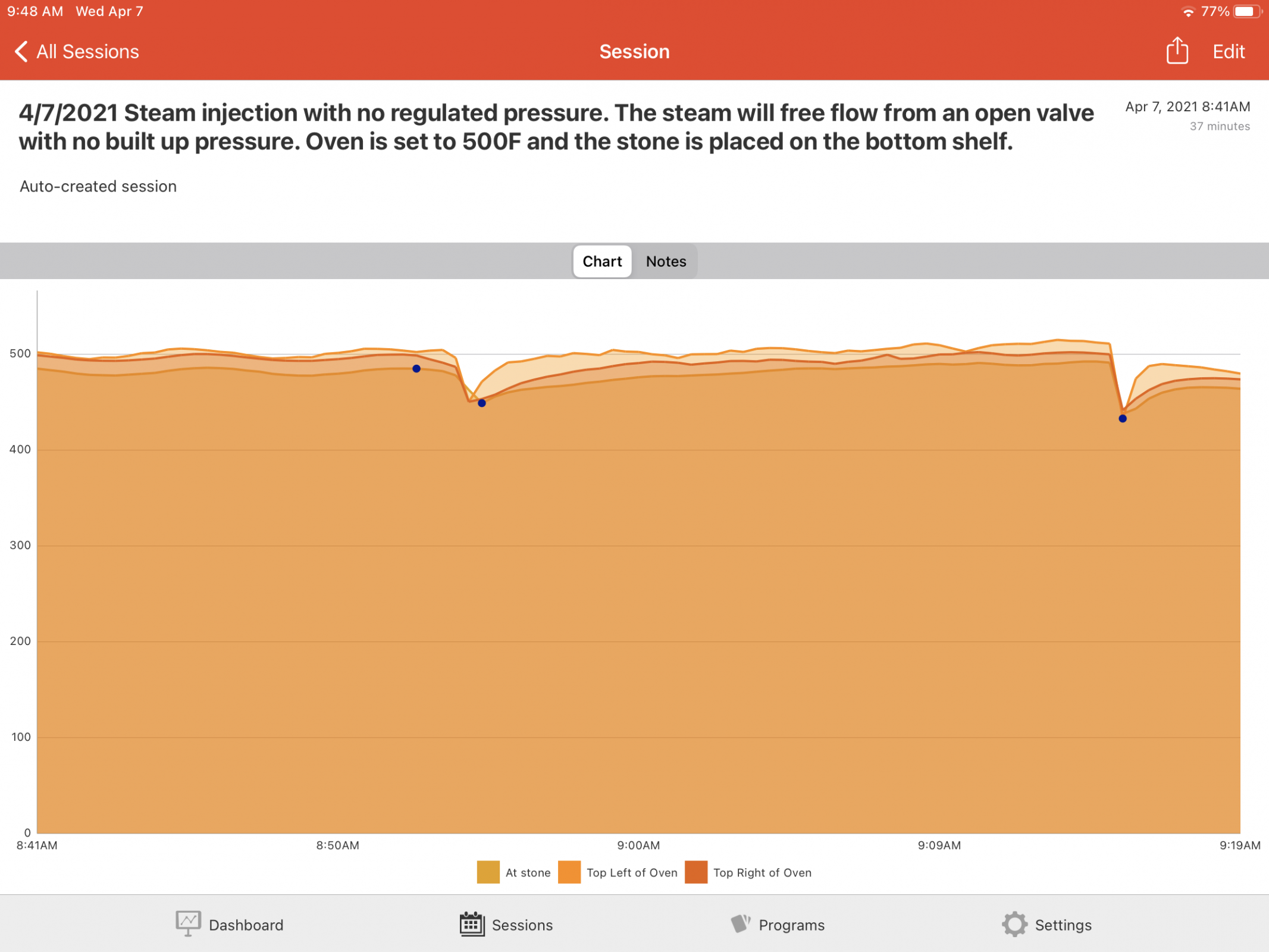

4/7/2021 Steam injection with no regulated pressure. The steam will free flow from an open valve with no built up pressure. Oven is set to 500F and the stone is placed on the bottom shelf.

https://share.fireboard.io/FC68FA

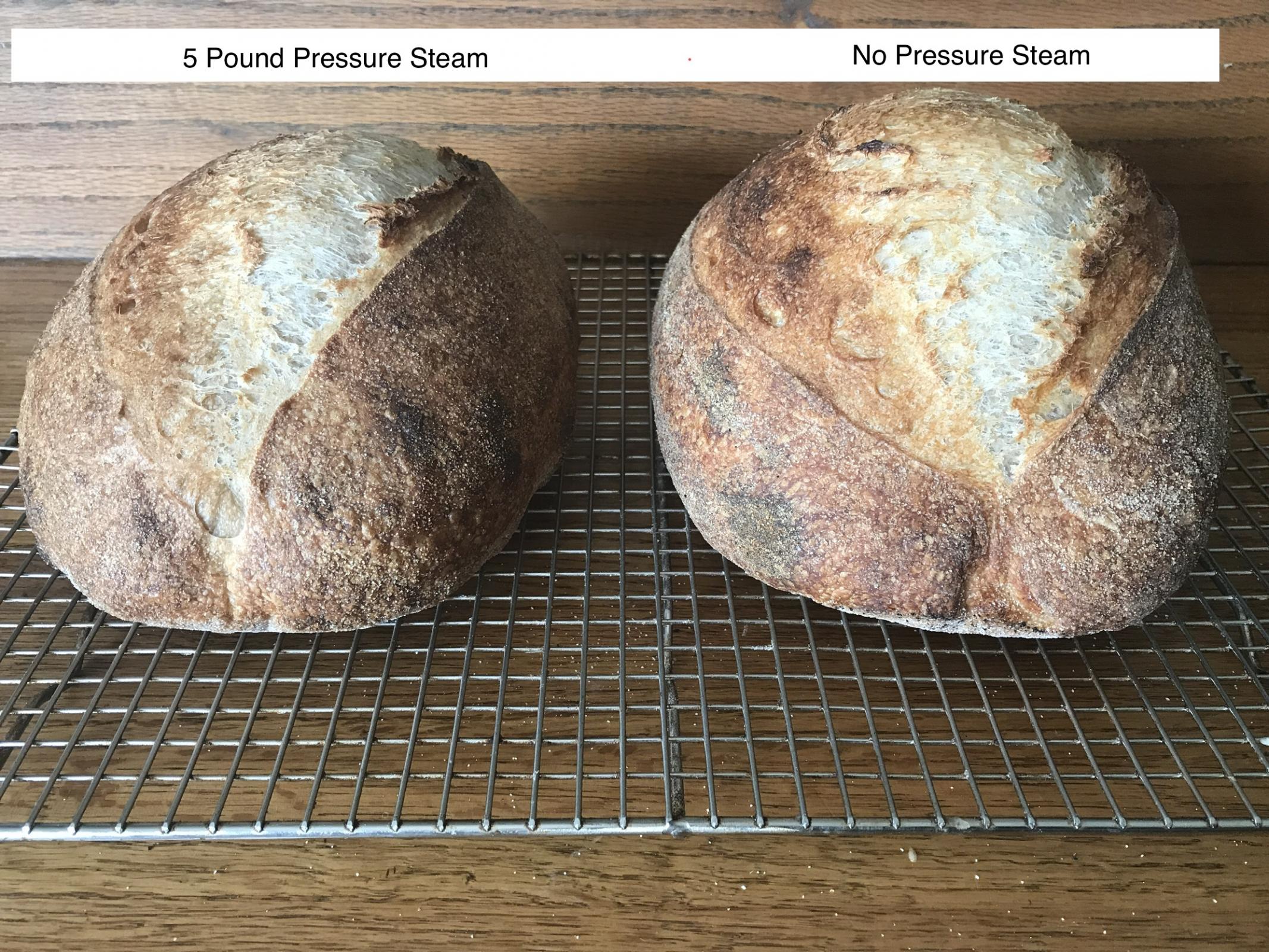

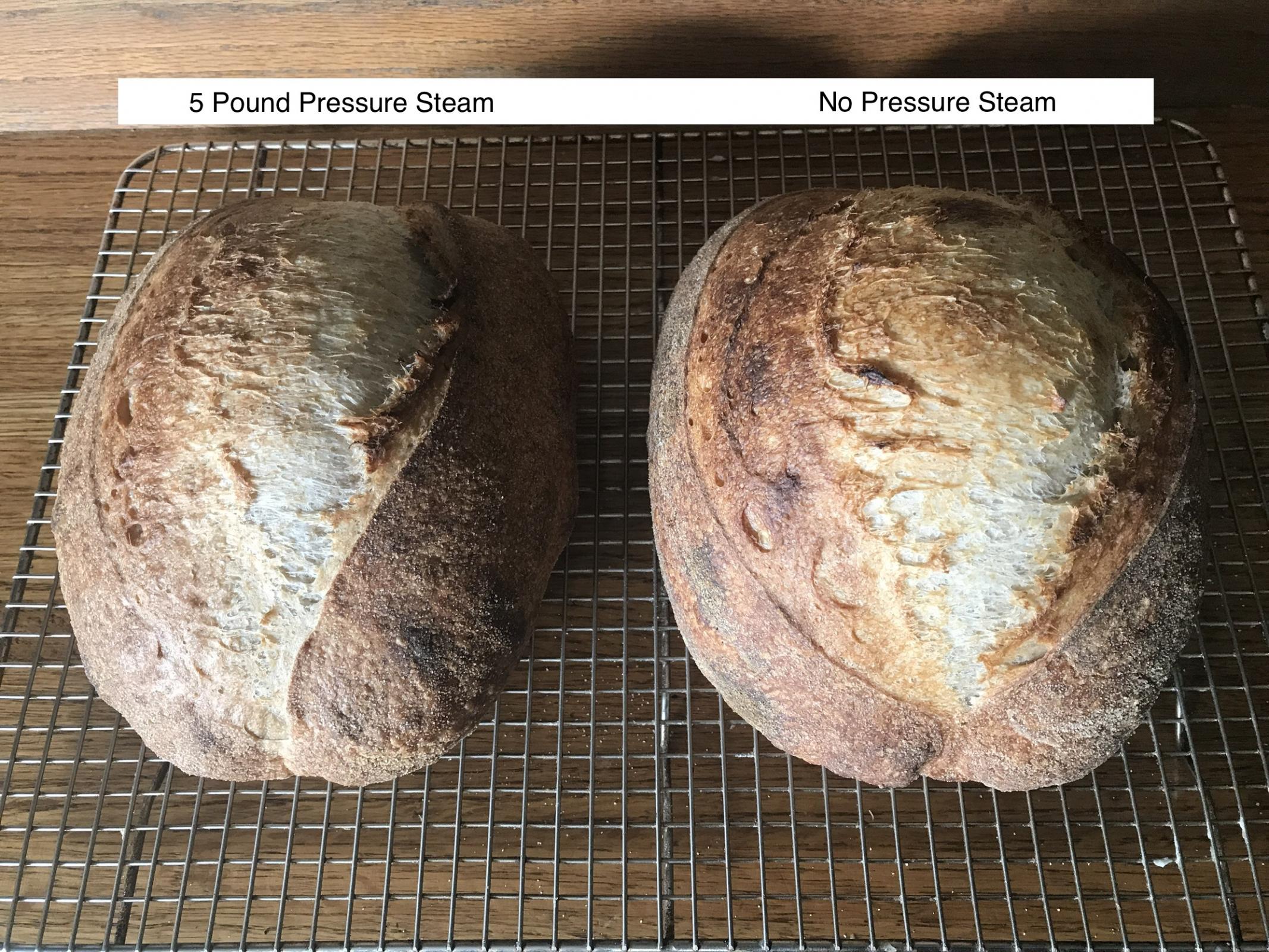

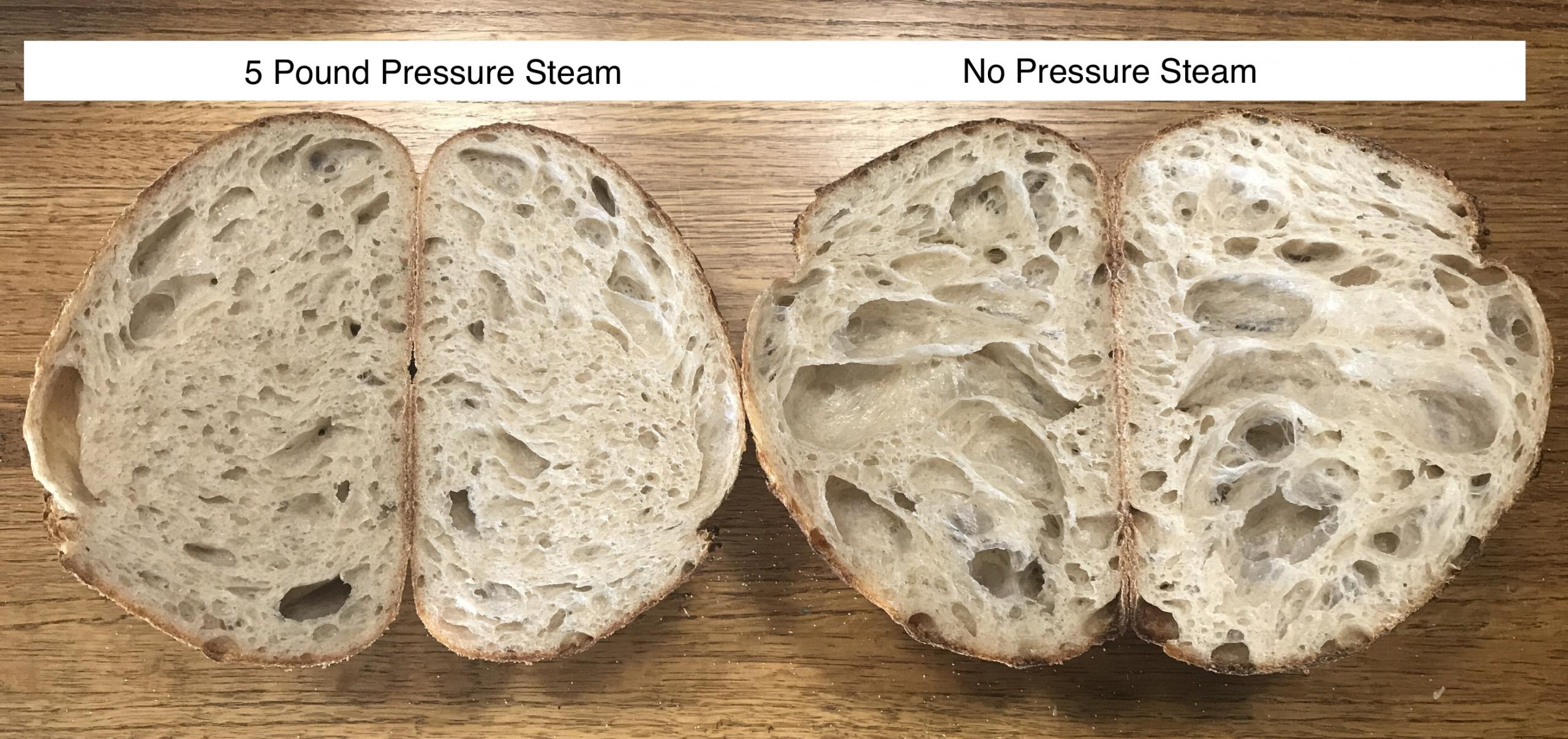

Here are the 2 resulting breads. They are Basic Open Crumb SD by Kristen of Full Proof Baking.

Notice how dry and lacking blisters they are.

The “No Pressure Steam” crumb was not my target crumb. I much prefer the “5 Pound Pressure Steam” crumb.

The video below shows steam produced without any pressure regulation. It is less than 5# because the wiggler never releases any steam.

Danny

Sorry, I keep forgetting... is your oven gas or electric?

Electric, with or without convection.

And an interesting result. I did try a similar trial a few months ago before my orifice plate development and I didn't notice any improvement; however my trial wasn't as good and thorough as yours because it wasn't a back to back trial.

I do wonder if your oven leaks steam and that is why the longer steaming period of the no pressure steam helped. When you put that steam pipe down the oven vent, how is the gap sealed?

Lance

My electric oven is designed to leak for air flow. It is my understanding that all modern ovens do the same. There are openings at the bottom of the glass door and also the vent under the control panel. The idea is that the air enters through the bottom of the oven door and escapes through the top vent. I read that this is supposed to facilitate more even oven temps throughout the cavity.

I do plug the top vent at times. But I am pushing so much steam that regardless of leaks I think the oven is getting huge amounts of that steam.

Beats me why the crust is not shiny and blistered more... Also, my oven cooks MUCH FASTER than the reports of other bakers. Don’t understand that one also. The oven was set to 500F and the thermal logs show it consistently close.

How fast for an average 800-850g dough weight loaf?

Lance, lean loaves from 500 to 1000g complete baking in 20-24minutes. They are fully baked. Baguettes ~17-20 min at most.

Seeded loaves take longer. I suppose because the seeds retain moisture.

That is fast. I am on 39 minutes.

Lance

I can’t remember baking a lean free form loaf that long Lance. 23-25 mins is the norm for most breads

I’m typically around 40 min for a 900 gm loaf.

Is steam really the problem? You are clearly getting excellent bloom.

Another thought for you: I started achieving a shiny crust only after I switched to a linen lined brotform for proofing. Somehow coating a basket with flour seems to surpress the sheen. It also hides the blisters pretty well.

-Brad

As I've said before, I reckon it's probably more to do with venting product created steam - to avoid soggy pastry for instance, and to avoid the hazard of a blast of steam in the users face when opening the door.

I have found that the dutch oven method ive been using for a few yrs, 480°- 25 min covered, 12 min dry gave me great results. But with steam i have it at 480°- 5 min steam and 17 min dry. Way faster. The nice thing with this set time is the bottom crust color is same color as sides. Very even bake.

Thanks, Brad. The great majority of times a linen insert is used. Linen was used on today’s test.

The linens are floured.

Appreciate the thought...

I don't flour my linen. My loaves are shiny by the time I remove the steam at 12-15 min.

My oven is relatively modern (all right, it's 20 years since I remodeled, yikes) but it has the same vents at the glass and the control panel that you mention. Your result is a head scratcher.

-Brad

You taught me how to get shiny and blisters loaves by retarding the couched dough without bagging.

It worked excellent for me. I remember using your technique with the Five-Grain Levain. HERE IS A LINK to an example of your technique. At this time I can’t find the exact post. Can you refresh me on the complete technique?

Here is ANOTHER LINK using your technique.

Danny,

Here is my post on the 5-Grain Levain CB. The photo is on the left side about 3/4 of the way down. What I do for this bread is place the shaped loaves on parchment paper (rather than a couche) on an inverted cookie sheet and place the whole thing in a bag for the overnight refrigerated retard. When I peel the loaves, still on the parchment, there is already a fine film of water, presumably condensate. I steam with a saturated towel from above the loaves.

With my more hydrated dough I use a lined brotform and retard overnight, again in a plastic bag. But the top of the loaf is against the linen so I don’t think the mechanism is the same. But the steaming method is the same. The majority of my breads are retarded overnight and are bagged, so maybe you are thinking of someone else.

Hope this is helpful.

-Brad

Brad, it is probable that I remembered it wrong. Pretty sure it was you that taught me that technique. Could have been some years back.

Do I understand your success that produces those gorgeous blistered, mahogany colored, glossy loaves?

Goal - to prevent anything that would dry out or absorb moisture from the crust

Please add or correct anything necessary. I have never baked a more beautiful loaf than those using your method. When I followed your instructions the loaves were gorgeous like yours and it never failed. Some how I forgot about it, but want to start using it again.

Brad - what do you think about placing batards seam side down in the banneton?

Thanks,

Danny

OH! Another tidbit I learned from you...

Batards that are slashed “sausage style” produced the most beautiful round slices.

Batards below are Hamelman’s Five-Grain Levain and were baked by Brad.

Danny,

With the loaf seam side up I the basket, the linen wicks away a fair amount of moisture. This gives a uniform amount of moisture on the surface. I have not had success with misting the loaves as the result is often a splotchy bake.

I have not really tried to place the dough seam side down unless I wanted the unscored rustic look.

-Brad

Brad, “ With the loaf seam side up in the basket, the linen wicks away a fair amount of moisture”

I was under the impression that the micro droplets of water on the surface of the dough was a good and lead to your success.

Have I missed something?

I think I had success with the loaf (Hamelman’s 5-Grain Levain) below by following your advice and retarding the dough seam side down on a parchment lined couche that was sealed in a plastic bag. The dough (seam side down) and the parchment were placed in the oven to bake. If memory serves me well the dough was covered with micro droplets of moisture when removed form the plastic bag after retardation.

Danny,

I was just reporting that my linen is very moist by the time I peel the loaves. Since they are cold, any steam in the oven should evenly condense directly on the loaves and I’ve always assumed that was the source of the sheen. I don’t get the same look with nonretarded loaves. The same reasoning applies to the 5-grain levain if it has been retarded.

-Brad

This is what I usually do. If the loaf can hold its shape, I put it on its parchment paper on a cutting board, cover it with plastic film, and retard it that way. I suppose if I had come up with some large plastic bags I would do it that way, but the plastic sheet seems to work well enough. The cutting board serves as a peel when it's time to bake, and the loaf slides right off, parchment paper and all.

TomP

Dan, Can you expand on what you mean by wet vs dry steam?

I was told that high pressure steam has less moisture than low pressure. So the steam made by boiling a pot of uncovered water is more moist than the steam made in a pressure cooker than has a 15# regulator (wiggler).

This old post from Eric Hanner is worth reading.

Lance

The comments from coffeeman are correct in that post.

In your experiment, the conditions of the steam in your oven were the same. The second the steam passed your valve it was no longer 5# steam, and the second it entered your oven it became atmospheric steam. However, the advantage of a pressure cooker, is that it allows you to add the same mass of steam at a higher rate. Aka... The time from closing the oven door until you have a saturated steam in your oven will be shorter.

My initial guess is that the 90 seconds in your first experiment wasn’t long enough and your oven air became dry before the bloom was complete.

Troy,

Ck out Test #2 above. The non-pressurized steam flowed into the oven without pause for the first 15 minutes.

Do you think the really open crumb is because you had so much more bloom there? Did the loaf expand beyond what the alveoli could sustain and they collapsed and coalesced?

Almost like the extra steam kept things too moist, maybe?

Yes, the oven spring caused the expansion of the alveoli. Because of this, I am baking 2 more loaves today that I plan to ferment more. Since large holes are not what I want, my theory is to ferment longer in hopes of exhausting more of the gas production before the dough hits the oven.

I actually spoke with Benny yesterday about huge oven spring and large alveoli. We both considered the idea that huge oven spring will result in very open crumb. Any thoughts?

This is how I plan to do that -

The BF was not allowed to ferment more than usual.

The overnight retard temp was raised tp 44-45F instead of the typical 39F. I expect this slight temp difference to cause the dough to continue fermentation considerably more than the typical 39F. Took a peek this morning and that seems to be the case. As an added benefit I am hoping that the flavor is enhance in the process.

What do other bakers think about this? Pro or Con.

Yep, that might work. It pushes you closer to the limit of going overproofed, but could help with gas expansion.

One other thing... I couldn't tell for sure, but in your first bake, it looked like you started loaf #1 very shortly after reaching 500 deg F. Loaf #2 benefited from an already well heated oven, and you might have experienced more oven spring from hotter surfaces. Again, couldn't tell for sure, so disregard if that's not the case.

Regarding your other question about timing... I would say 5# and 0# steam both for 10 minutes.

Troy, the oven was thoroughly preheated for both bakes. The thermal charts are started after the oven comes up to temp.

Nice! I have a 4-probe digital thermometer that I use for smoking meats. Your charts have my wheels turning on how I could use them and still keep the oven sealed well. Some good information there...

Troy, take a look at this link.

https://share.fireboard.io/DE3D01

It is an interactive chart showing the bake that is going on right now. You can zoom in and out, read notes and many other things. Play with it to see what you can do. The notes will help a lot in understanding what is happening at that particular time. For example the note will indicate when the oven door was opened and you’ll know the exact time and be able to see the temp swings.

I think you’ll have a blast with it...

That is slick! Both loaves look good to me. Nice and shiny with some great blistering!

With the difference in shape it's hard to say, but looks like both loaves have about the same volume? Loaf #2 certainly taller/plumper, but Loaf #1 being longer?

The session and test are complete. Brad’s Blister Method worked miracles for me. I bet they’d blister without any steam at all.

Revisit the link for all updates for this test.

https://share.fireboard.io/DE3D01

Wow Dan, if you ever wanted blisters galore and a shiny crust you have done it now, congratulations on your new method!!!

Benny

You'll probably get better at it than me.

-Brad

Danny, please can you clarify what was the retarded storage procedure and containment equipment used for these loaves. I am confused as to what exactly "Brad's Blister Method" is.

Lance

Troy, loaf 1 was shaped by rolling up. During the shaping of loaf 1 it was apparent that the dough was weak. Because of that loaf 2 was shaped like Kristen’s method for batards. That is why #2 has more loft, I believe.

Read all of it.

The article had me thinking about using a cold cover on a preheated stone. See THIS LINK. The thermal data indicates that lightweight metal covers heat and also cool extremely fast. Other thermal data indicates that steam does not cool the oven near as much as we thought. See the thermal charts on the original post.

IF the unheated cover should heat rapidly, maybe the protection from radiant heat (that causes premature hardening of the crust) and also wetting the inside of the metal cover (to initiate instant steaming) or using 1 or 2 ice cubes would help. Initially the dough would be heated from the bottom with the super heated stone.

Been thinking about THIS GLASS VESSEL for a long time. Just placed the order so I can watch the magic :-) my attic is full of contraptions like these. LOL

Danny, have you tried misting the loaves with a fine water spray just prior to putting in the oven?

I have tried it and it did improve the crust sheen somewhat.

Lance

A big yes to misting!

Covered vessels have produced better results, especially if the cover is closely sized to the expanded dough. If the cover is too large the results are not nearly as good.

THIS is an example of my obsession with steam. The aluminum cover fits tightly over the baking stone. The results were less than stellar. I think the cover was too large to contain the steam in close proximity to the loaves. The cover was also heavy to handle when super hot.

My very best visually pleasing crust results were produced with Brad’s technique. I realize this is a cosmetic thing, but who doesn’t like baking gorgeous looking breads :-)

I think my oven bakes FAST & DRY. But for the life of me I can’t figure it out. Maybe I need to focus on sealing the fent in the bottom of the door.

The use of steam is an important factor in the production of good bread, if you have steam then you can make better bread, or at least you have the facilities for making it better. Steam in the oven is necessary, it improves the bloom and appearance of the loaf, helps the dough to rise evenly in the oven, and in so doing tends to lessen excessive oven spring, and if properly used gives to the bread a thin crisp crust. Too much however will give a glaze on the crust which is not wanted except on certain types of bread, principally Vienna bread and rolls, and similar varieties of Continental breads.

Wet steam should be allowed to enter the oven before setting and while the bread is being set; this gives a little moisture or dew on the loaves, preventing them from becoming dry and almost baked on top before it is possible to fill the

BAKING

115

oven and close the door of the baking chamber. It is of no use taking great care in covering up the dough to prevent dryness on the top, and then immediately setting the loaves in the very dry atmosphere of the oven; the steam cock should be slightly turned on during the setting of the batch, and, when the door is closed, 30 seconds should be sufficient at full pressure to get in the oven all the steam necessary for the baking of ordinary bread as distinct from the Vienna type; the loaves will then keep moist during the time they are expanding in the oven, and baking will proceed in an atmosphere created from the evaporation of the moisture from the loaves. This method will not give a pronounced glaze on the loaves; where such is desired, the steam should be kept turned on for 3 to 5 minutes after closing the door.

The effect of the use of steam is that a fine film of moisture is deposited on the surface of the loaves during the dough's expansion which prevents the dryness and often colouring on top before the gas has caused the loaf to spring to its full capacity, thus helping to prevent unsightly breaks and misshaped loaves; steam should not be used for too long a period, and so prevent the natural moisture from leaving the loaves; use of steam prevents some of the loss of weight due to the baking process.

If an excessive quantity be used, that is, if the steam cock be left turned on too long a period, the crust will be tough and leathery, and unlike that which baked bread should possess.

WHAT STEAM DOES AND ITS EFFECTS

Wet steam facilitates and helps a normal oven expansion of the dough by preventing crust forming too quickly, acting as a medium for mellowing the heat from the oven crown. If used in moderation, gives a pleasing bloom and helps retain the moisture in the loaf, with a corresponding lessened loss of weight; helps the symmetry and shape of the loaf by keeping dough moist during the first few minutes of the baking period; assists toward the formation of a thin crisp crust, and imparts a rich appearance. By preventing excessive oven pull it assists in the production of an even texture. It tends towards the better baking of the loaf by preventing early crust formation, the heat being better able to penetrate to the interior than if a hard crust was quickly formed.

It is obvious then that the use of steam in the oven has sufficient good points to warrant its universal adoption in bakeries solely from the point of view of assisting towards the production of the perfect loaf. The final baking off should be in a dryer atmosphere than is required during the first few minutes.

Steam at 15 to 20 lbs. pressure at the boiler is sufficient for bakery use, as the drop in pressure in the piping will give you about 10 lbs. at the oven, and, if anything is superior to that, then it is steam from a lower pressure. At a higher pressure you are not getting wet steam unless a reducing valve is used, and it is just as well to use none as to have dry steam. For the sake of safety or assurance that you are obtaining wet steam, the boiler used should be set to blow off at 20 lbs. pressure, and when sufficient steam is not obtainable at this pressure, then a bigger boiler is necessary and not a higher pressure. It should be remem bered that moisture is wanted and not steam as steam; moisture to prevent crust forming too quickly on the loaves, moisture sufficient to keep the surface dust while expansion of the loaf takes place.

Boilers installed in bakeries for the purpose of supplying hot water are usually at too high a pressure to be suitable for oven work, although these can be readily adapted if in the connecting pipes to the oven a patent valve is fitted to allow boiling water to enter the steam pipe; the high pressure steam will force the water into the steam line and so create wet steam. Where a large boiler is in use, sufficient wet steam could be obtained for a number of ovens if the boiler is working as low as 5 lbs. pressure, but for oven work, to work a boiler exceeding 20 lbs. is a waste of fuel, and the steam produced is of no use for oven humidity. Ovens should be as near as possible steam-tight, at least there should not be defective dampers; no oven is so tight that steam will not find an exit, and, when steam can be seen emerging from the bottom of the oven door, then the oven is full of steam; it may be seen emerging from the tops of the door before it comes from the bottom.

It is important to remember that the oven should be hotter when using steam, particularly portable steampipe ovens which are inclined to flash heat. A drop of more than 40 deg. F. may be shown on the oven thermometer when the steam is injected, and if the oven is not solid, the baking results will not be satisfactory. Too much steam is not good practice. No steam at all is better than too much; used in moderation, it is an improvement; used in excess, it destroys the signs of under-fermentation by creating an unnatural appearance on the loaves. Judiciously used it gives a crisp crust; too much, and you can expect a crust resembling leather.

Are you planning on another trial, Danny, where you run the 5psi steam for longer?

Lance

Yes, the bake will take place in a couple of hours. What do you propose?

10-15 min @ 5# of pressure. (Keep in mind the valve will need to be cracked in order to keep the pressure up)

What about the second test dough? Yesterday I ran 5# for 90 seconds and 0# for 15 min.

I am of the opinion that retarding dough at the appropriate temperature allows fermentation to continue. This produces CO2 which is then absorbed by the liquid phase of the dough. Since the dough goes from saturated with CO2 to unsaturated as it cools, this allows for the absorbtion (and thus storage) of additional CO2 during retard. If you retard too cold, you don't generate enough CO2 to fully saturate the dough. So it is important to go to the retarder soon enough that the dough can still expand without overproofing but no so soon that it fails to completely proof before you bake. This is balanced by the increased solubility of CO2 at lower temperatures.

If you get the timing and the retard temperature just right, the dough emerges from retard ready for the oven. The steam then condenses on the surface assuring adequate moisture to fully gelatinize the starch (source of shiny crust) and cooks the surface starch to form a gas-tight membrane. Then as the oven heat penetrates the dough, the local temperature rises and the dough becomes supersaturated with CO2. The CO2 then comes out of solution as a gas but cannot escape through the now gas-tight membrane and thus forms blisters just under the surface. Once this has taken place (which requires wet steam that quickly condenses on the dough surface and sufficient steam to fully gelatinize the starch, and sufficient heat to cook the surface starch) you can allow the steam to dissipate for the remainder of the oven cycle.

The remaining CO2 stored in the cool dough comes out of solution and contributes to oven spring (this is actually a major mechanism for inflating the alveoli as the bread bakes). Thermal expansion of the CO2 is the other mechanism that generates oven spring, but that happens later in the process at higher temperatures. The CO2 comes out of solution at much lower temperatures (while the loaf can still expand through cracks, slashes, and blowouts and the crust is not acting as a pressure shell). When the starch is fully set it becomes structurally strong and the alveoli leak letting the CO2 escape (to see what it looks like find good micrograph of sliced bread). That is the earliest point where the bread is "baked" and can be removed from the oven without falling or having a gummy crumb.

Doc, “ Once this has taken place (which requires wet steam that quickly condenses on the dough surface and sufficient steam to fully gelatinize the starch, and sufficient heat to cook the surface starch)”

Can the wet steam that condenses on the dough be seen with the naked eye? I want to be sure this is occurring during my bakes.

You are so correct about getting the fermentation of the BF and also the fermentation during retard dialed in...

In the typical case of retardation in the fridge @~39F fermentation almost ceases. The dough can remain in the fridge without a lot of critical timing. BUT, when the retard temps are raised, even slightly, fermentation proceeds at an exponential rate. I fermented the last 2 test doughs @ 45F and they over fermented in 12 hours. I anticipated fermentation during retard so the BF was cut a little short. In spite of this both doughs over-fermented. To succeed with higher fridge temps the BF will need to terminate sooner and/or the retard temp lowered a few degrees to compensate.

This method of fermentation makes the timing much more critical than typical ~39F retardation. An aliquot jar for BF may be in order...

Yes, wet steam contains entrained water droplets, while dry steam does not. And when you mix wet steam with dry hot air, the dew point of the mixed gases goes up not down and to get water to condense on the surface of the dough you have to drop the temperature of the diluted steam to below the local dew point. My suspicion is that in a commercial deck oven immediately after loading, the principle heat transfer mechanism from the oven heat source to the dough is radiation, which can move a lot of heat quickly even though the air temperature in the oven is quite low since the radiation is weakly absorbed by the air and the water vapor. This allows you to simultaneously have a very hot oven and a relatively cool charge of mixed air and steam. Cool enough to allow the steam to condense on the cool dough surface until the dough has heated up above the local dew point. Once convection has begun to equalize the air (air + steam) temperature, the oven surface temperature, the heat source temperature, and the surface temperature of the dough, the dough surface rises above the point where the steam will condense on it. After this, the steam adds no value to the heat transfer process.

So you should be able to see water on the surface of the dough if you are getting condensation.

@ Danny - in case it is not clear, if the convection fan is on, then the oven temperature equalizes very rapidly and reduces the time during which the steam can condense on the dough. Your steam injector may serve as a proxy for a convection fan by stirring up the air. In fact, this may suggest that there is a benefit to letting the oven cool off a lttle while you load the bread.

You might want to put a conical aluminum foil heat shield (shiny side out and open end pointing at the bread) around one of your temperature sensors to act as a radiation barrier to see if the air temperature is different from the radiation temperature.

Doc, I have never thoroughly understood Dew Point, and I live in southern Louisiana. LOL

I understand the simple explanation, but questions remain. I think the dew point is the coolest air temperature at which the moisture in the atmosphere can no longer remain contained within. At this temp moisture droplets form and come to rest (because water is heavier than air) on near by objects. Is this correct?

Point #4 -

I assume that the dew point in an oven varies according to the humidity in the home and also atmospheric pressure. So an oven in south Louisiana and an oven at super high elevations in Montana (hi Don) will vary greatly. Is this correct?

I have many questions. There is so much to learn.

BTW - Doc, your thought that the steam flowing into the oven from the pressure cooker is causing convection, is interesting. It seems obvious that the air within the oven has to be circulated as the steam enters the cavity. I will be mulling this over and over.

The convection fan is never running during the initial phase of the bake when steam is being generated.

on the dough during the early minutes of some bakes. I haven’t made a systematic study of the conditions but can tell you that it occurred with room temperature (rather than chilled) dough, since the loaves weren’t cold retarded.

Paul

If 2 loaves were baked in the same oven at the same time, one loaf cold from retardation and the other RT since it was final proofed at room temp, wouldn’t the colder dough gather more condensation?

Water will condense on the dough until the surface temperature exceeds the local dew point. Assuming that the dew point in the oven is relatively high (like 80-90°C) then water will continue to condense until the dough gets that hot, and a loaf that has a lower initial temperature has to absorb more thermal energy before it will reach the temperature at which condensation stops.

It seems likely that a colder dough would condense more steam than a warmer dough. One way to find out...

Paul

Just dropped in today. Wowed at your testing, Looks like your doing well and that's good news.

It's been a very long time. Just saying. My loaves baked in my Clay Bell are covered in those birds eyes you like. Have a wonderful bloom and crust I love.

When I bake bread..we no longer consume near as much. I use this CBell and a covered enamel pot,,both fit nicely in my oven together. Towel steaming is reserved for when baking on a heated stone. I'm satisfied with these indoor oven methods.

What have I been doing,,:)) Right now I'm temporarily working with vision in only one eye and can't wait to get back to my sewing and bake a couple of loaves. I just had my first Great Grand child born to my oldest grand daughter and SIL this March. He's in Palo Alto and I won't be able to see him in person for while :(.

Sylvia

Great to hear from you, Sylvia. You and your Steaming Towels are legendary.

I have been fortunate to bake nice breads, but my never ending quest for perfection and inquisitive nature is too compelling to resist :-)

Baking on covered vessels have provided very good results, but I hate the fact that I can’t watch the show. THIS is my latest purchase and it is due to arrive in the next week or so. Will publish my findings.

https://www.amazon.com/gp/product/B07MF3S5JK/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

Hope you regain full site soon.

Congratulations on the grand GRAND baby...

Danny

Seems you forgot to put in the link Danny, but I assume you are getting some glass bowl for baking?

When I bake a single loaf I always do it in a preheated upturned pyrex casserole dish (this is European pyrex that is proper borosilicate glass, but I think American pyrex should work too...). It works really well, and indeed I wouldn't want to go to a cast iron dutch oven or any other non-transparent vessel! Really nice to see the oven spring, and see when it stops to remove the cover. I got the idea from Patrick Ryan's video on youtube, and that's how I actually started baking a year ago.

Ilya, thanks.

Here is the link.

https://www.amazon.com/gp/product/B07MF3S5JK/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

Looks good, as long as it's tall enough ? I'm sure you'll love having a covered vessel where you can see the oven spring and browning without opening.

Remembering Glass bowls and observing the baking process. Do you remember back in the day, when Susan baked her loaves in what was called the magic bowl or I believe. She covered her loaf with a glass bowl and baked it. It put on a show.

Sylvia

That’s what I’m looking forward to. I shoot time lapse in-oven videos to study the event.

*** HERE *** is an example.

Very interesting read and a very good idea, I also have an issue with my oven having air coming out but from the top door so steam is always an issue. but I noticed that when I bake 2 loaves at a time with steam on a baking steel it will give me a very nice oven spring. This may be because temperature has drop while dough is being loaded(Which is what I need to check and learn)Thanks for this wonderful post!

Carlo

Carlo, the steam escapes my oven from the top of the door, but it enter through the bottom of the door. Open your oven door and look at the very bottom edge for holes. My dooe gasket is purposely left opened (about 5 inches) at the bottom.

I tried this steam thing in my domestic oven several times but it didn't seem to do much for the crust. In the end I got myself a hand-held plant sprayer & just before the dough goes in the oven I spray it a couple of times, sprinkle a little flour on top then slash it. It produces a perfectly fine, non-teeth braking crust. It may not look as spectacular as some loaves I've seen here but then I'm not baking bread to look at, just to eat & enjoy.

I often get shiny loaves that look almost as if they have been lacquered. If I don't quite get that, I expect to at least see a matte sheen. Here's an example:

This loaf, like most of mine, was proofed free-standing on a sheet of parchment paper covering a plastic cutting board. It was covered by a piece of plastic wrap during proofing. The cutting board serves as my peel, and the parchment paper goes into the oven along with the loaf. I remove it 20 minutes later, when I turn the bread end for end.

I use a cast iron steam pan filled with rocks in the bottom of the oven, underneath the baking steel. I slide the loaf in, close the door, put on an oven mitt, pick up the Pyrex measuring cup with 1 - 1 1/2 cup of tap water, and toss it onto the steam pan. Then I close the door right away. My oven has a large vent and steam will pour out of it copiously.

Typically I do a bulk ferment at room temperature for 10 - 12 hours, shape, and proof for 1 1/2 - 2 hours, though sometimes I do a cold retard during bulk or proof. During bulk ferment the dough will typically triple in volume.