Since this is a process of discovery more than an exposition of well understood science, the update number in the title will change when enough significant changes have accumulated that you might want to re-read from the top. At some point it will stabilize but in the beginning it is somewhat volatile as I discover/uncover truth and apply a dope slap for what proves to be erroneous.

The time has come to see if I can make an acceptable injera at home. I found a few injera-related posts here on TFL though while I found them interesting (and one provided a compact summary of an excellent YouTube video) none seemed to improve on what I found on YouTube and in some quite excellent reference sources.

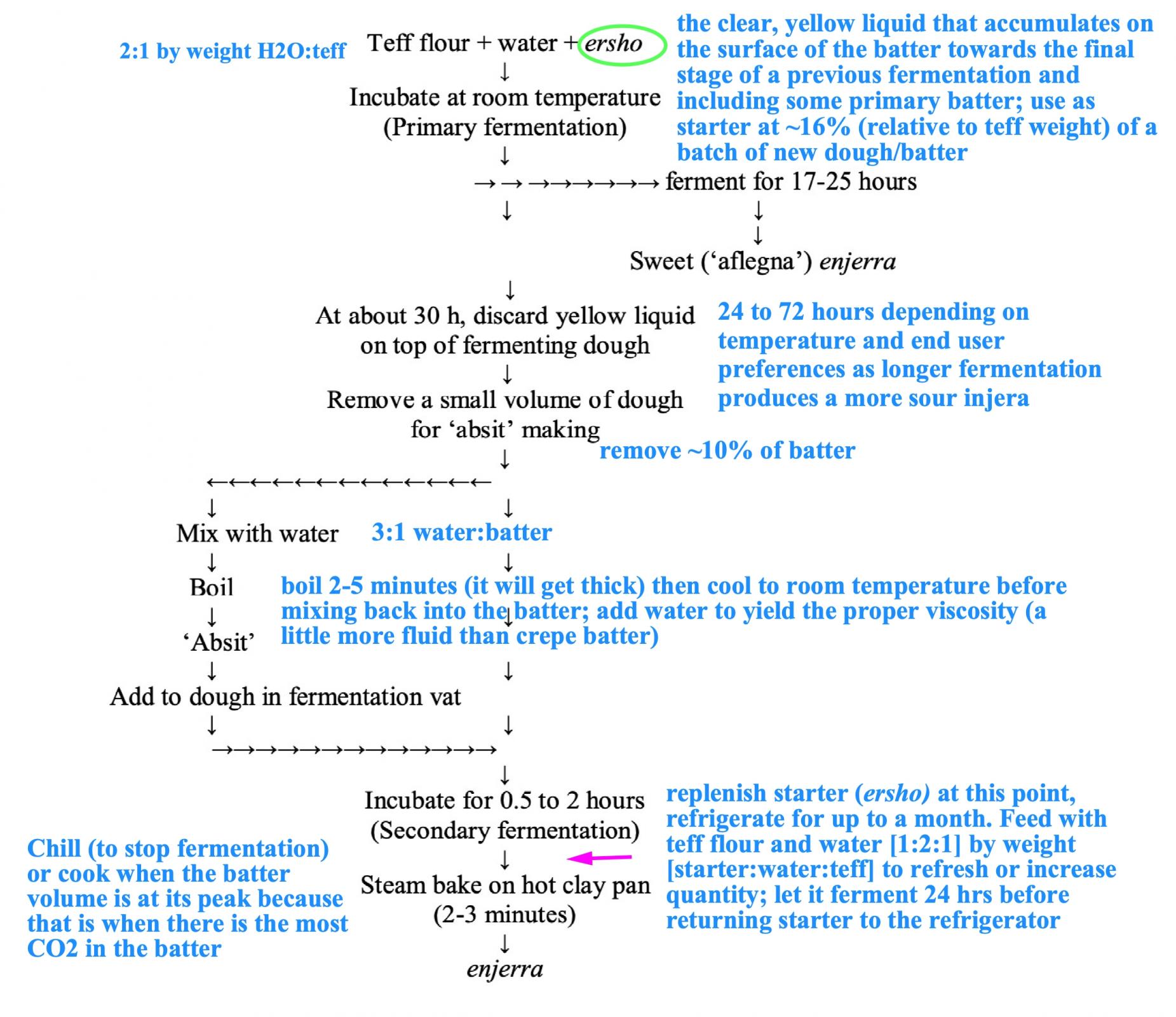

Having watched a number of videos explain how to make injera, I found some common threads which I have tried to interpret using my general understanding and knowledge of other fermented foods (mostly sourdough and idli/dosa). I present here my evolving observations which are open for discussion and prone to elaboration, enhancement, and correction based on superior knowledge from other members of this community:

An outstanding publication on Ethiopian fermented food containing a fairly complete section on injera

Ethiop. J. Biol. Sci., 5(2): 189-2245, 2006 [section on injera begins on page 205]

Annotated injera flow chart from linked paper:

It appears that an injera starter culture contains multiple yeasts and multiple LAB, though it is not clear to what extent there is a progression of activity from one yeast and LAB to others over the course of a typical fermentation cycle.

The pouring off of the liquid layer that accumulates on the surface of injera starter and batter is essential, and discarding the liquid layer results in loss of soluble compounds (amino acids, sugars and minerals) and a large portion of the microorganisms. It seems that one function served by the liquid layer on the surface is to keep mold and aerobic yeast off of the batter. I found that after a few days a layer of aerobic yeast forms on the surface of the ersho, and mold will eventually begin to grow on any bits of batter that remain on the side of the fermentation container. Thus washing the sides of the container before you begin the fermentation is an act of sanitation and contamination reduction while pouring off the ersho gets rid of the aerobic yeast that tends to accumulate there. As a result of experimentation I have discovered that if you run the fermentation near the optimum/elevated temperature (37°C/99°F) the aerobic yeast and mold never show up, perhaps because the cycle is so short. They may be there but not at levels sufficient to cause a problem.

The use of self-rising flour (apparently an adaptation of the Ethiopian method and now commonly used in NA) seems to be a way to get by with a less than fully active starter, letting the baking powder in the self-rising flour serve as an alternate source of CO2 to produce "eyes" in the final fried injera. Another possibility is that the microflora in injera are incompatible with wheat flour, or wheat flour will not ferment quickly enough to generate the required CO2 and an alternative is to use baking powder. There is no evidence that the resulting injera are of lower quality in any way. In fact, in many parts of Ethiopa (and in NA) grains other than teff are used to make injera, including sorghum, millet, wheat, barley, and corn (maize).

I found a paper that used modern PCR methods to characterize the yeasts in injera batter and there were clear differences in the constituent yeasts between injera batters prepared at home, in hotels, and by what were characterized as microenterprises (which I presume means that they were producing commercial injera).

Pichia fermentans was the only yeast that was found in all 97 of the injera batter samples (which may indicate that it is brought to the mix by the teff flour itself); and our old friend Saccharomyces cerevisiae was also found in all of the batters prepared in hotel kitchens (though it does not speculate as to whether the source was intentional addition or cross contamination from other yeast-based products being produced in the hotel kitchen). This may indicate that any yeast that will tolerate the low pH conditions of the injera batter is sufficient to produce the CO2 needed to make "eyes" (bubbles) in the resulting injera (or not if baking powder is needed to provide additional CO2).

A final warm fermentation followed by cooling the batter may be just a retardation step that drops the temperature of the batter and allows any additional CO2 (being produced in the batter) to be absorbed into the liquid phase, but the guidance to use the batter when the secondary fermentation peaks (I assume that means that the height of the batter in the fermentation container peaks) is consistent with frying when the CO2 in the batter is maximized. The CO2 then comes out of solution when the batter heats up on the mitad (frying surface) and makes the "eyes" as the bubbles are called. The size of the eyes seems to depend on the viscosity of the batter with a thicker batter producing larger eyes, and a thicker/less desirable injera.

Covering the injera for a period at the end of the cooking cycle keeps the surface from completely drying out by retaining moisture from condensed steam on the surface of the injera while allowing the dough to fully cook and solidify.

It is clearly not essential to mix injera batter by hand and any mixing method that fully hydrates the flour(s) and eliminates lumps is adequate. I found no obvious reason not to use a whisk, blender, or simply a spoon.

In some of the YouTube videos there is a step where the batter is put into a blender and blended for perhaps 10 seconds to eliminate the "sandy texture" of the batter. I haven't figured out what this is about. The boiling of some batter with water for a couple of minutes to make the 'absit' which seems very similar to making a tangzhong (water roux) is claimed to have the same effect of smoothing out the batter texture. I found another video where the batter was blended after incorporation of the self rising flour to get rid of lumps.

To test the hypothesis that absit is just a tangzhong, I mixed 50g of brown teff flour with 250g of RO filtered water and heated it to 65°C/149°F while stirring, as I would do to make a tangzhong. The behavior was exactly as expected, the mixture thickened and stirring with a whisk was sufficient to see the bottom of the pan so the starch in the teff is gelatinized at about the same temperature as wheat flour. A search for gelatinization temperatures confirmed that teff gelatinizes at 145–176°F (63–80°C), a few degrees above wheat [124–140°F (51–60°C)].

I am struck by the similarity of the injera process to making dosa, where the final batter viscosity is set by the need to spread it suitably on the frying surface and depends on many factors which make it difficult if not impossible to predict exactly how much additional water will be needed. The acceptable band of viscosities is quite narrow and when it is too low the injera produces fewer eyes and large cracks form between isolated islands of cooked dough. If the viscosity is too high the injera does not flow to the edge of the mitad, is thicker than desired, cooks more slowly, has larger eyes, and is harder to handle.

Having spent a couple of weeks verifying the described features and issues, it was time to try some variations on the general theme and see if there was any significant difference in the result.

First, I tried raising the fermentation temperature to the reported optimum of 37°C/99°F and was amazed by the increase in fermentation rate and reduction in the time required to deplete the fermentable sugars and halt the generation of CO2. At 99°F the primary fermentation was complete in less than six hours (since it is a very liquid batter with no gluten to give it structure, it may rise and collapse multiple times before the yeast run out of food). Mixing the batter using 120°F water produced a 100°F batter so that there was no delay in getting it up to the 99°F fermentation chamber temperature and reduced the time needed to rise and fall once and develop a nice sour flavor to about 4:30 from mixing the ingredients and the secondary fermentation completed in about 90-120 minutes followed by 90 minutes in the refrigerator to slow it down, cool it off, and allow it to absorb the CO2 suspended in the batter as bubbles. This CO2 promptly comes out of solution to form the "eyes" when the batter is poured on the griddle.

If the objective is to cook the injera when the CO2 trapped in the batter is maximized, the strategy that seems to achieve that end seems to be to allow it to ferment until it reaches 80-90% of maximum height without collapsing then refrigerate the batter to dissolve as much of the trapped CO2 in the liquid phase as possible.

There is some point at which if you don't refrigerate it, the continuing production of CO2 will outstrip the capacity of the batter to hold it and the batter will collapse anyway. If you begin cooling it too soon, the batter cools down and stops producing CO2 before it has depleted the fermentable sugars. So it is a fine line that encourages a slightly early termination of secondary fermentation to avoid a collapse before the batter has absorbed the maximum amount of CO2.

It is also possible that if there are fermentable sugars remaining in the batter when the temperature has stabilized at the final storage temperature, fermentation may continue (slowly) for an extended period of time keeping the batter loaded with CO2 and capable of being converted into freshly baked injera with lots of eyes. Since the source of fermentable sugars to support the secondary fermentation is the abjit, it may be (speculation here on my part) that increasing the amount of absit that is added back to the batter may influence how long the batter can be stored and still be used to make high quality injera, though unless the absit is made with excess water, increasing the absit may make the batter too viscous to pour properly.

Thus I offer my current modified improved method for making enough batter for 1.8 - 14" diameter injera cooked on a 16" griddle:

{why 1.8 injera you ask? - because that much fits into a one quart wide mouth Mason jar without overflowing}

Ingredients:

40g starter + 250g water (@110°F )+ 180g teff (@105°F) + 5g salt (added to the water)

then for absit/tangzhong

25g teff + 180 water make absit (~1:7)

Process:

- Place the starter in a bowl and add the warm water, whisk to combine

- Add teff flour and slowly whisk it in until the batter is smooth (a whisk with fewer rather than more wires helps keep the flour from splattering)

- Pour into a container with sufficient head space to allow a 70% volume expansion (it will expand by at least 50% and you don't want it to overflow).

- Place the batter in a 99°F fermentation chamber or well controlled low temperature oven (combi. or an oven with a light on that you have confidence will settle at ~99°F) and let it ferment for 6:00; remove and stir down the foam then put it back to ferment for another hour. At 5:00 stir down again and let it sit at 99°F for another 20 min or so; it should not rise again. This seems to be the indication that all of the fermentable sugars have been consumed. Taste to be sure that it is appropriately sour (if not let it sit longer since yeast and LAB have different cycles).

- Mix and cook the tangzhong by combining the 25g of teff flour with the 180g of water, mixing until they make a smooth slurry. Cook over medium heat until the tangzhong reaches 180°F, stirring constantly; when it reaches the fully gelatinized state the scraper will leave a permanent streak on the bottom of the pan. Remove pan from the heat and continue stirring over a bowl of cool water until the tangzhong reaches ~130°F before adding to the injera batter and whisking it in.

- Adjust the viscosity at this point if needed. I have found that it seems still a little thick at this point but will thin out during secondary fermentation. Put the container back into the 99°F fermenter and allow it to undergo a second fermentation for about 90 min to 2 hrs;

- Then transfer it to a refrigerator without mixing and leave it to cool off for 90 minutes or so. The level of the mixture will recede to near the level at the beginning of the secondary fermentation when it is fully cool and the CO2 has been fully dissolved in the batter. Stir well to re-suspend the solids (resist the tempatation to make viscosity adjustments here) and pour onto the griddle.

- Heat the griddle to 330°F (based on IR thermometer measurement) and spray the griddle with a very small amount of non-stick spray (vegetable oil + lecithin) before pouring batter in the middle and picking up the griddle and rotating it to spread the batter to the edge. I found that 325ml at the appropriate viscosity (to test the viscosity, it should pour smoothly from a 3 oz ladle in a few seconds at a height of about 8" without breaking up into droplets) will spread all the way to the edge of a 16" griddle.

- Turn up the thermostat to 400°F and cook uncovered until about 70% of the surface looks dry and then put the lid on for a minute (steam will be coming out of the lid by then) before removing. Wait for the bottom surface to become sufficiently cooked that there is an obvious separation at the outer radius where you can get a thin Teflon or other high temperature spatula (or lefse stick) under the injera then use a sefed to transfer it from the griddle to a cloth surface where it can cool off and lose some of the moisture. If you use a lower temperature you can turn the griddle up to 400°F after taking the lid off to hasten the final cooking stage so that it comes off the griddle sooner and more easily. But you have to wait for it to be ready - otherwise it will stick badly to the spatula.

- Do not try to stack until they are fully cool and no longer sticky on the surface.

- If you find that there is not enough dissolved CO2 in the batter to make the eyes you like, add about 2t of baking powder (not baking soda) per quart of batter and stir it in. Wait a minute or two before continuing to fry injera. I have found that at this concentration the baking powder leaves no distinctive taste.

Jan 28, 2022 - a note of some potential significance:

I was pointed to a video on YouTube where a chef makes beautiful injera without any absit, which poses the question "what makes absit important"? Thus far I have been operating under the assumption that the absit is needed to pump up the dissolved CO2 in the batter just before cooking the injera to form the eyes. But it seems clear that the incorporation of absit followed by a secondary fermentation is perhaps not an essential step if you can get the CO2 into the batter via another route. This opens up a range of options going forward. I am already fermenting injera batter in eight hours which bypasses mold and aerobic yeast growth on the surface of the batter as well as reducing the planning time. Making the absit and timing the addition relative to when you want to cook them remains a process constraint that now may conceivably have a workaround. In the video you will notice that the chef has three griddles, of which two are from ADDIS. This is the model that I finally selected after some considerable study, but I will not make this into an ad more than to say that my rationale for selecting it turned out to be valid.

July 30 2022 - see an added comment below with a 30 July 22 date for how to refresh and maintain an injera starter.

- Doc.Dough's Blog

- Log in or register to post comments

This is delightful. A very thorough self-discussion, question and illustration of injera. I wish I knew more about the subject but I am certainly learning a lot and enjoying it!

It, once again, shows that people have more similarities than differences. Across the planet-desert,mountain,fields-we ALL enjoy a well-fermented bread to wrap our food in.

Keep going! Thank you!

Watching multiple YouTube videos just shows how a wide range of practices all seem to produce a similar end product, which I take as an indication that the underlying microbiology is pretty reliable so long as you provide food and don't kill the critters that are doing the work.

I first tried transferring one of my wheat sourdough starters to teff, and that worked well in terms of producing an acidic end product after 12 hrs, though since there is no gluten in teff the relatively low hydration to which I mixed the starter (5:13:17) opened up cracks through which the CO2 escaped without rising (expected). After 12 hrs the mixture had lost ~ 250mg of CO2, and had a pH of 4.2 so less active than when it is fed wheat flour but that was just the first feeding. At that point I added enough water to form a residual, relatively clear layer on top after the sludge had settled. It is still making some CO2 with an occassional bubble. I will watch this at room temperature for a few days to see if the pH drops further. I expect the pH to end up around 3.5 if the native teff LAB are numerous enough to become dominant before the food supply runs out.

Next I am watching a teff + water mix (55g brown teff flour + 110g RO filtered water at mid 70's room temperature) to see when it begins to spontaneously ferment. The expectation is a few days. After 12 hrs there is a thin layer of clear tan liquid on top and the pH is ~6.2 and no indication of fermentation (bubble formation) but before bubbles will show up the liquid has to become saturated with CO2 which will normally drop the pH to below 6.0. Based on what I have read and observed on YouTube this is normal. Historically (for me anyway) when the initial pH is that high some contaminant species quickly begin to multiply, produce (sometimes nasty smelling) gas and die down only after the pH begins to drop. This batch was mixed in a glass jar and thus is too heavy to weigh on either of my high accuracy scales so I will not be able to accurately measure the early phases of CO2 production.

Having added some teff flour and water to a little wheat sourdough starter and let it ferment overnight, then after weighing it to determine how much CO2 had been created (presumably by fermenting the added teff) I added some additional water to thin it out and form a protective cap over the settled teff paste, and I thought it was done. Now after another 24 hrs there is a burst of activity with active fermentation taking place in the solids under a layer of clear brown (some might call it yellow, others would call it gray or black) liquid. I am suspicious that there are two independent fermentations taking place in the same container:

1. a continuation of the fermentation of the original wheat-based sourdough feeding off of sugars derived from the teff, and

2. a new spontaneous fermentation of the teff based on different microflora

with the initial weight loss representing the consumption of residual glucose/maltose from the wheat starter and any immediately fermentable sugars (maltose, fructose, and short glucofructans) perhaps liberated from the teff flour by amylase enzymes that came with the wheat sourdough. The spontaneous fermentation of the teff may be a totally independent process based on the activity of yeast and LAB that are unique to teff. The timing (delayed from the initial wetting of the teff flour by 48 hrs, but enhanced by the acidity carried over from and newly created by the wheat sourdough) is consistent with acceleration of the spontaneous teff fermentation that normally takes ~72 hrs.

The container that holds the simple teff flour plus water [1:2} mixture has now (after 18 hrs) begun to show evidence of fermentation, not by active bubbling but by expansion of the combined liquid + sediment layer. The first photo below on the left is from 12 hrs after the initial wetting of the teff flour; the second photo was taken 8.6 hrs later after 21 hrs; the third photo is after 35 hrs; the fourth photo is after 61 hrs.

12 hours 21 hours 35 hours

61 hours

Note both the increased height of the top of the liquid layer in the second photo (compare to the edge of the blue tape), and the increased width of the liquid layer. It appears that by 21 hrs, the hydrated teff settled to be about 93.8% as high as it was at 12 hr while the height of the top of the liquid had increased by about 2.4% so that the liquid layer was considerably thicker. What is the phenomenon that is driving this? My first guess is that the total volume increase reflects some CO2 generated that has not yet been fully absorbed into the liquid but is also not buoyant enough to float up through the teff to the surface as a bubble, and the settling of the solids could be either compaction of the particles under their own collective weight or part of it could be that some soluble components of the teff have now gone into solution allowing the solids to further compact themselves. There was evidence that the top of the fermenting teff had been somewhat higher between 21 and 35 hrs but by the time I took the third photo (35 hrs) it had receded to about where it was at 21 hrs.

pH history:

Elapsed Time pH

12 hr 6.2 layer of clear liquid on top

21 hr 4.6 island of fermenting teff floating on top

35 hr 4.26 still some foam on top but rate of fermentation has slowed down

61 hr 4.18 continues to slowly ferment at room temperature

73 hr 4.14 occasional bubbles and a small amount of floating aerobic yeast (this should be a mature starter)

81 hr 4.19 still bubbling slowly, pH has shown an uptick that is outside what should be related to temperature or instrument error.

Whatever the active organizm is, it is present at substantial levels in the raw teff flour and it seems to ferment well at fairly low temperatures (17-25°C per the reference).

The color of the liquid layer at 21 hrs was light enough to declare that it was a "yellow" which one author opined might be from dissolved riboflavin produced by the bacteria. At 35 hrs the turbulence from the fermentation was still enough to keep the liquid layer from clearing up. At 61 hrs there was little foam on top of the liquid layer but the pH seemed to have stabilized around 4.2.

I'm following with interest. We have domestic injerra in Toronto which I enjoy, and injerra imported from Ethiopia, which I find way too vinegary for me. We have a large Ethiopian community here and I source all my coffee beans from a local market for roasting.

I’ll be following along as well since I make Injera to go with a dish called Doro Wat. The unfortunate thing is that I have no idea what either should taste like since we have no restaurants that make these dishes here. I gather that the injera should be somewhat sour and I was able to achieve that by mixing half a cup of sourdough with 2 cups of teff flour and water and letting it sit for 24 hours. Previous quick versions found on the web didn’t have the tang.

Your post above explains why my Injera didn’t have many eyes. Most of the CO2 must have escaped as it did not have a layer of liquid on top. I will have to ferment it longer next time and add water part way through to create a seal on top.

I hope you post your most successful recipe and method.

I suspect that if you think of injera as just a sourdough starter that you run on teff flour at 200% hydration, you will be in the ballpark. It is the secondary fermentation that I find unusual and I struggle to understand. The two things that would seem to impact it are the pouring off of the accumulated liquid (where a lot of the LAB apparently reside) and the adding back of some absit (or another fermentable component like wheat flour) which seems to raise the level of fermentable sugars. I found a statement last night that the primary sugars that support the secondary fermentation are sucrose and fructose which could be products of amylase activity. There is a sequence of succession in the microbiology and the yeast activity is apparently low until late in the game, enhanced by higher acidity and perhaps the pouring off of the liquid containing the majority of the competing bacteria. But different sources report different yeasts so perhaps it really doesn't make too much difference so long as there is one or more that will do the job of loading the batter with CO2. All speculation of course.

Ok I was below that since I was using volume measurements and I did 2 cups of water to two cups of teff flour. One cup of teff is 151 g so rounding off, two cups are about 300 g and the water was 454 g. I’ll adjust that next time to 600 g of water and pour off the extra water. Thank you!

I think that 200% by weight turns out to be about where you wind up with 1:1 by volume if you sift the flour but of course everybody's cup of (teff) flour is different. But weighing it will get you to where it needs to be, and even then I didn't have very much surface liquid until after some fermentation had taken place. I currently have two small batches that differ by 24 hrs in age and the second one seems to be following the first, with both slowly fermenting on the counter. I have a big styrofoam box (3" walls) with a heater, a muffin fan, and a PID controller with adjustable hysteresis but it doesn't have any cooling so I have to operate it at 80°F or higher which is a little above room temperature. I may initiate another starter and let it run at 81°F for a few days (assuming the weather behaves) to see if things go faster or turn out differently.

fermenting the dough? I only did 24 hours. I realize that temperature is a factor. My room temperature is about 73F but my oven with the lights on and the door cracked open is about 82F.

To be clear, I also used 1/2 cup of sourdough starter from the fridge and 1/2 tsp Himalayan salt.

Once you have a starter that has adapted to teff I think the 24 hr primary fermentation and a shorter secondary fermentation are probably appropriate, with the secondary fermentation stopped at peak volume. But if you don't have a robust teff starter a longer primary fermentation may be required. I am not there yet so I don't have enough samples to give you very good guidance. And as you will see below, the fermentation temperature makes a huge difference!

The salt is a variation that has not shown up in any of the documents or videos that I have seen. A few people seem to clean their mitad with salt and some sprinkle salt on the mitad before pouring the batter, but I have not seen any that ferment with salt.

I tried to find the site where I got the original recipe and of course I couldn’t, but many others that were similar in using sourdough also used salt. 🤷🏼♀️

ETA: Ha ha! I found it. It was a recipe from a post here. https://www.thefreshloaf.com/node/18141/happy-accident25-lbs-teff-flourpart-1-and-2#comment-120291

I guess I wasn’t supposed to ferment the salt with the dough. It should have been added later. 🤦🏼♀️

Here is the one I copied down. This one does ferment the salt with the rest.

https://www.thefreshloaf.com/node/4786/making-ethiopia-injera-bread#comment-150838

Though not sure when the salt should be added. See more about adding salt here.

In looking more closely at what I thought were residual bubbles on the fermenting starter I discovered that while there are some small bubbles, they are not where I was looking, and what I thought were patches of bubbles which (based on the comment below by Danni3ll3) turn out to be an aerobic yeast that can only live where it has access to O2.

Right click on the image and open in a separate tab which you can then zoom to see a few bubbles around the periphery but the light colored patches out in the middle of the image are the aerobic yeast feeding off nutrients brought to the surface by bubbles (which then dissipated). This may be another reason to insist on a layer of water on top of the batter (to allow this yeast to grow but isolate it from the batter)

Scroll down a bit and you will see a picture that looks similar. Apparently it’s not mold, but something perfectly normal. Looks like you are on the right track.

https://www.daringgourmet.com/authentic-injera-ethiopian-flatbread/

Thanks for the contribution! One of the really great things about TFL.

I came across an honors paper written by Scott Strobel in 2012 at Penn State.

I am just beginning to read but it is loaded with useful data from some very nice fermentation experiments.

One item of note: mixing teff with buckwheat flour caused the fermentation to stop at a higher pH than other combinations of flour.

Another item of note: teff and teff + sorghum exhibited the most rapid fermentation, and the optimum temperature was 37°C/98.6°F

And that is just in the abstract.

I have started a new fermentation using some (15g) of the ersho and some (15g) of the batter from the 4-day old starter plus 60g of teff and 120g of water and I am running it at 37°C/99°F. This is my first starter refreshment using backslop from the prior batch and it has taken off like a rocket with the combination of fresh ersho and elevated temperature. This perhaps should have been between 10 and 15g of starter instead of 30g but it was more than adequate. The description should be a refresh at [30:120:60] (starter : water : flour) fermented at 37°C. It will ferment 7 hrs at optimum temperature (37°C) then continue at 81°F overnight while a sourdough starter shares the temperature controlled box and we will see where it is in the morning. Time tagged photos below. Worth looking at at full resolution (right click on the photo and select view in a separate tab). On day 3 the starter was stirred and transferred to a clean jar. The pH was down to 4.24 at 48 hrs. I am beginning to wonder if there is a missing LAB component in my teff flour since none of the starters I have built so far have shown a pH below ~4.0. When fermenting idli, there is a third stage (after the batter has reached pH=4.2 where Pediococcus cerevisiae becomes the dominant strain and drives the pH down to around 3.5 (which is considered sour in idli but that is where injera batter is expected to stabilize).

T=0 T=4:38 T=6:58 T=41:44

With the third round of spontaneous fermentation of an injera starter completed and stable (though with a pH above 4.0) it was time to make a batch of batter and cook some full sized injera. My Addis Griddle arrived from Cincinnatti (more about that later, but I am quite happy with its performance on a test batch of crêpes) so I have a quite uniformly heated Teflon-coated grill to cook on. The following spreadsheet was built to plan the quantity of teff and ersho starter that I needed to make two big injera and have a little left over (to cover for inaccurate projections and process losses along the way). The plan was to initiate the batter using 20% pre-fermented teff starter/ersho, discard 10% of the total weight when pouring off the cap layer before making the abjit. Remove 10% of the remaining batter, dilute it with 3x water and boil it for 2 min to make abjit, then add it back to the batter to initiate the secondary fermentation. I assumed that I would hold back 15% of the total yield as a somewhat batter-enriched ersho that would be held over for the next batch, fry two 350g injera, and allow for 20g of residual batter in the container and on the spoon and coating the Pyrex measuring cup that I would use to pour the batter onto the grill.

In following this plan, everything worked fine for the first 5 minutes. Then I discovered that I had not used a container that would allow for the suggested 50% expansion during fermentation and transferred the batter to a 2qt Mason jar. In the process I added 20g of water to the original container to wash out the residual batter. Now I had a little more liquid in the batter than initially planned. The starting pH was 5.54 and the batter was fermented in a large temperature controlled styrofoam box (2.5" wall thickness) at 81°F, and checked periodically to observe the behavior (see photos below).

Over the 24:30 of the primary fermentation at 81°F the pH dropped to 3.87 which was lower than any samples tested up to this point (the three spontaneous fermentations I had initiated so far). The expectation is that it may eventually drop to ~3.5. The question is why none of the other trials reached a pH below 4.0. Perhaps it is just a matter of time until the essential LAB species that produces this last burst of lactic acid has the opportunity to grow to a sufficiently large numerical density that it can perform its function in the available time. It was noted by Ashenafi that the Ethiopian injera makers told him that a new mixing container had to be used (without washing it out) to make three batches of injera before it worked properly.

The clear liquid that formed the cap layer at the end of the primary fermentation was poured off (77g - which was a little more than 10% of the fermented batter + liquid) and held in reserve to be added back as needed to adjust the viscosity after mixing in the absit.

64g of batter was removed, to which 192g of water was added (3x). The resulting mixture was brought to a boil over medium heat, stirring constantly with a silicone spatula. This is necessary as the teff tends to settle to the bottom of the pan where it gets more heat and if not stirred constantly will thicken quite dramatically in a place where you can't see it and would probably be difficult to remove from the pan when you got done. After boiling for two minutes the absit was removed from the heat, stirred (with the bottom of the pan in a bowl of cold water) to cool it down to ~100°F, then added back to the batter and stirred until fully incorporated. The viscosity of the resulting batter was judged to be thicker than desired, and 59g of the 77g initially poured off before making the absit was added back to adjust the viscosity before putting the batter back into the fermentation chamber at 81°F. A short video [17 sec] is available on YouTube if you want to see what the absit looks like when it boils. As the teff flour reaches its gelatinization temperature [145–176°F (63–80°C)], first the amylose and then the amylopectin become hydrolysed, combining with the water to form a modestly viscous starch paste. The gritty feel of the batter completely disappears from the abjit after it has been hydrolysed so I suspect that the particles that contribute to the gritty feel are starch granules or a starch complex of some kind which is destroyed by heating in the presence of water.

T=0:00 T=3:00 T=4:00 T=5:30 T=6:30 pH=4.11

T=7:30 stable cap T=7:30 stirred down T=9:30 pH=4.11 T=11:40 pH=4.02 T=21:00 pH=3.93

T=24:30 w/ absit pH=3.87

After 3:30 of secondary fermentation (28:00 elapsed time) the pH had declined to 3.82 with a thin layer of clear liquid on top. The batter was hen moved to the refrigerator to stop the fermentation and lock the CO2 into the liquid phase of the batter - though the total batter volume indicates that there is little if any CO2 trapped in the batter as gas bubbles. The viscosity looks about right so I do not expect to have much ersho floating on the surface and I may wind up saving some mature batter as starter for next time.

Enquiring minds want to see the end result!

Very interesting and informative. Mixing with buckwheat flour increased final pH after fermentation is peculiar to me, I wonder if buckwheat has less sugar to ferment so resultant pH is higher?

When I thought of trying to mix corn with teff, I immediately thought: how would nixtamalization affect injera's fermentation? There was research on nixtamalization of African millet and resulting protein and mineral content increased with an overall smaller colony of LAB, consumer acceptability increased as well.

It sounds like nixtamalized injera may be more nutritious and tasty.

From what I have read so far injera is made from available local flour but the preferred solution is teff-based. Many use tef + local to cut the cost and produce a reliable fermentation. I don't have enough experience to judge. I have discoverd that running the fermentation at 37°C/99°F allows it to run to completion very quickly (6-7 hrs with 16% prefermented flour @ 99°F). And with the faster fermentation I found that I didn't need the extra liquid so I could drop back to ~160% hydration from 200% then not add much water at all (if any) along with the absit. And instead of taking batter to make the absit I tried just making a teff tangzong with 1 part teff and 5 parts water by weight (and taking the temperature up to ~90°C or even to boiling where both the amylose and amylopectin will gelatinize because teff gelatinization occurs at a higher temperature than for any other grain I found) where the amount of teff in the tangzhong was equal to 10% of the weight of the teff used in the primary fermentation. When I did it that way and added the absit/tangzhong soon after the batter initially collapsed from the primary fermentation, the secondary fermentation would come roaring back after 10-15 minutes and collapse on its own after 45 - 60 min. So the objective became to cool it and make injera before it collapsed during the secondary fermentation. This provided a big load of CO2 in the batter (cooling before the secondary fermentation completes helps by increasing the solubility of CO2 so that it does not just bubble away). And the CO2 provides a high density of eyes on the surface of the cooking injera.

I will put masa on my list of experiments for augmentating the teff. And I will wait for you to report back on how it goes with nixtamalization of the whole grain teff. I suspect that grinding soaked teff will turn out to be problematic given the extermely small grain size. Perhap re-drying after soaking and before milling might work.

Doc, following your research into Injera making, are you able to give us (or at least me) a quick idiot's guide to making it?

I am somewhat confused about the different steps in the process and their order.

Lance

Check at the bottom of the original post. There is now a new baseline process example.

Thanks Doc - I will get some Teff flour and give it a go.

Will a standard SD starter do as the initial 63g starter?

Lance

You will need to spontaneously ferment some teff flour and water @200% hydration and room temperature for 48 hrs (until it stops foaming and the solids begin to settle). Refrigerate and use as starter. It will be better after you have replaced it with finished injera batter. Academic literature says it needs at least three cycles to mature so you can try that at ~6hr per cycle at 99°F using 1:2:4 (starter:teff:water) before you go for a larger batch. Note that there is no salt in the batter. That is something I am going to challenge shortly just to put a bound on salt tolerance of the yeast and LAB.

Adding salt to injera batter at 2% of the teff flour does not inhibit the yeast or the LAB that are the major players in producing the characteristic sour flavor.

I fermented a small test batch of injera batter at 99°F with 1% salt in the batter and it had no detectable impact on the fermentation so the next day I ran a batch at 2% salt. Still the timing of the fermentation was identical to no salt and 1% salt. The fermentation was rapid and began to collapse/recede at 4 hrs at which point I added the absit/tangzhong and let the secondary fermentation go for 20 min @ 99°F before moving it to the refrigerator where it rose quite a bit over the next 20 min and then began to recede as the CO2 was absorbed into the liquid phase of the batter. After a total of 90 min of chilling the batter was uniformly cold (1 qt wide mouth Mason jar cooled fairly quickly) after which it was cooked. The 2% salt is a better match for the sour of the injera even when the process is run at a relatively high temperature.

Edit 12/29/21 - I have subsequently made it a practice to screw down the cap on the 1 qt wide mouth Mason jar that I use for fermentation after adding the absit/tangzhong. The pressure rises substantially from the CO2 produced and keeping the container sealed encourages it to go back into solution as it cools off. After an overnight refrigeration the pressure is just a little above atmospheric and the dissolved CO2 makes for plenty of eyes in the resulting injera. As an aside, I would note that I left a batch for three days without the cap sealed so added 1/2t of baking powder to the batter just before cooking the injera, whisking it in and letting it sit while the griddle came up to temperature (so not long) and the eyes in the resulting injera were quite nice with no apparent change in the flavor profile - I suspect because the acidity of the batter is so high to begin (meq of H+ per mole of lactic acid equivalent) that 1/2t of baking powder in 500ml of batter is inadequate to substantially raise the pH or drop the acidity very much.

Doc, I wonder if the same technique could be applied to crumpets? I (and no doubt many others) struggle not to produce blind crumpets.

Perhaps if the latter part of the ferment was sealed (with due care regarding overpressure), then the eyes might be encouraged?

I know the baking soda technique is recommended for crumpets, but I'm not convinced it works. You might gain from the soda, but maybe you lose from the loss of gas when stirring it in.

Lance

PS. I have my teff flour now, so Injeera will be a New Year project.

Re crumpets - salt and baking soda are stirred in at the same time in the recipe I use so I would be stiring anyway

If not enough holes, try adding more water bit by bit to see what works best for you / reducing amount of batter in the rings

Looking forward to an injera blog!

Thanks for taking the time to research, distill, and document this wild/natural fermentation injera recipe, with so many quick variants out there. My idli making has benefited from your previous effort (especially lately). This is another one of my favorites (I could eat a whole plate of these), and I feel better equipped to tackle this on my next attempt. I still have a few bags of whole teff in the cabinet. Anecdotally, I found the (blended) whole teff to be much more active than the pre-milled flour in my somewhat improvised experiments. I frequently see reports of a "symbiotic yeast" associated with teff when searching for injera (here for example), but have never found a primary source describing this. I'm curious if this truly implies some mutual benefit. Did you encounter any discussion of this in your research?

Thanks for the encouragement. I am glad that others are able to put my "notes to self" to good use.

Try working your way through the references in this document:

https://journalofethnicfoods.biomedcentral.com/articles/10.1186/s42779-020-00069-x

There are a lot of references, and I found many of them to have full text versions available.

One quote:

Wheat and rye sourdough might be considered to be in the same category as the yeasts and LAB involved seem to be present in the grain though it takes time to develop the starter through repeated refresh cycles. For dosa, I have found that about 1/4t of old dosa batter is adequate to initiate a very rapid fermentation but as you know you don't need it to get a reliable result. Injera seems to be similar except that most practitioners use batter held back from the prior batch (back slopping) to initiate the next batch. I am not surprised by your observation about fresh ground teff having a higher level of activity than commercially produced flour. The source of the yeast/bacteria may not always be the same. Sometimes from the soil and other local crops (contamination of the grain), while sometimes from the grain itself (symbiotic association) as seems to be the case with idli/dosa.

After another six months of experimentation I have settled on a solid method for refreshing and maintaining an injera starter. This assumes that you already have a starter so the initial stage of establishing a spontaneous fermentation is something you will have to struggle with. Maybe I will work on that in the future.

I make and maintain injera starter in 5.5 oz polypropylene food service cups with a lid to match.

The ratios are 10:36:24 by weight [starter:water:teff flour] and if you use 1g = 1 part then his yields about 70g of starter in a cup that weighs 4g.

I let it ferment in my fermentation chamber (81°F) for 6 - 12hrs until it is full of bubbles before transferring it to the refrigerator. The photo below shows what it looks like after 3 hrs of fermentation. You can see lots of small bubbles toward the bottom and fewer at the top where it is quite foamy after only 3 hrs. The initial height lined up with the top of the blue tape so by the time I took the photo there had been ~30% volume expansion which is pretty active. The source starter for this mix was refreshed yesterday rather than having spent two weeks in the refrigerator, but it is pretty fast in any case. I suspect that it would work just fine if it was refreshed at room temperature though I am in the habit of using a temperature controlled chamber just for consistency and because I have one.

I have run a lot of experiments to determine how long it will last in the refrigerator at 38°F before it must be refreshed. The answer is that two weeks of refrigeration has very little impact and refreshed starter still grows well after four weeks, but while I will make injera directly from 2 week old starter, I would refresh a 4 week old starter once before initiating a batch of injera.