Hello all,

I would appreciate any ideas on what I can do to take this loaf to the next level.

Here is the formula:

- 92% Cairnspring Mills Sequoia T85 flour

- 5% Nash's Hard Red Whole Wheat Flour

- 3% Fairhaven Mill Whole Rye Flour

- 82% Water

- 2% Salt

- 6% Prefermented flour

Here is the process. Temperature is in Fahrenheit. (I know this is obvious, but I teach math and am incapable of not giving units of a number. Also, I can't stand that we continue to use imperial units the US.)

- Autolyse was 1.5 hours.

- Starter was incorporated 3.5 hours after being fed.

- After 5 minutes of mixing, give the dough 30 minutes of rest before adding the salt. Did Rubaud mixing for about 8-10 minutes.

- FDT was 77 degrees. My proofer was set to 77 degrees. (Nailed it!)

- Folds were done in half hour intervals. The first two were stretch and folds, the last six were coil folds. One interval was 45 minutes while I was walking my dog. I forgot to put the dough back in the proofer during this time, and the dough cooled down to 73 degrees. It took about 90 minutes to get it back up to 77 degrees.

- Bulk fermentation was a little over 8 hours.

- After preshaping I gave the dough 35 minutes of bench rest.

- Shaped the dough into a boole and gave it 30 minutes of rest at room temperature before putting it into the fridge.

- Left the dough in the fridge for 22 hours.

- Baked for 40 minutes in a Dutch oven. First 20 minutes with the lid at 475 degrees. Twenty minutes without the lid at 450 degrees.

Here are some pictures.

Thanks in advance for any feedback!

SImple: give it to me.

What didn't turn out as you hoped/expected? It's perhaps not the final word in open, airy crumb but then there's not a speck of plain white flour anywhere in the recipe either!

For me, I might even prefer a slightly more closed crumb because I enjoy that in a non-white bread. Not exactly 'denseness' - more that I just like more bread in every bite!

I'd possibly pre-shape a little more strongly in an attempt to achieve that (something I resolved to do after a recent pane di semola) but that's just personal preference.

I think Benny or Mini will be able to tell you to the minute/degree what you need to do : )

(Perhaps I should have left the commentary to them but that's a really nice looking loaf.)

d

Come up to the Pacific Northwest and I'd be happy to share a loaf with you!

I do want to open up the crumb on this bread. (I'm not interested in open crumb for the sake of open crumb. My understanding is open crumb is a side effect of bread with really good flavor.)

Even though there is no white flour strictly speaking, the T85 flour has had some bran and germ removed. I'm under the impression that T85 flours can be regarded as 50% WW, but I'm not completely sure of this. It turns out that the Tartine Bakery uses flour from Cairnspring Mills so I believe a baker with more skill than me could produce a loaf with a more open crumb using this flour.

I also prefer a more closed crumb in a non-white bread. I have a mostly whole wheat pan bread that I'll share on a later post as I need some help with that one as well.

A spread of butter and some of my homemade fig jam.

That oughta' do it!

Just sayin'

Duly noted!

Although I tend to prefer butter and honey with this bread. The complexity of sourdough paired with honey is out of this world.

Have to say that is a good looking loaf of essentially 100% whole grain bread.

A couple of comments I might offer, you did quite a few folds during bulk, were that many necessary? The more folds you do and the later you do them in bulk will create a more even crumb. If the dough doesn’t require a fold because it hasn’t relaxed, don’t do a fold. So fewer folds especially in the final couple of hours of bulk.

Another think to try, shorten bulk fermentation, shaping earlier and give the shaped dough in the banneton more time warm before cold retard. Because you are giving the dough more fermentation after shaping you can attain a more open crumb rather than shape, which can close the crumb, a short bench rest, then refrigerate.

As I said though, that is a fine loaf and none of my comments are criticisms whatsoever, just comments trying to answer your questions.

Benny

I wouldn't regard this bread as 100% whole grain. I'm still not clear on what a T85 flour is, but I know it has some of the bran and germ, and it feels more like a white flour dough than a whole grain dough.

I've been wondering lately if stretch and folds have diminishing returns. Good to know that the number of stretch and folds that I do contributes to a uniform crumb. I frequently use this bread for sandwiches, so if I can achieve the same flavor as a bread with a more open crumb, that would definitely suit my purposes.

How will the shorter bulk fermentation affect the flavor? I'm not interested in open crumb for the sake of open crumb, flavor is my main motivation. (Perhaps I'm being too rigid in my thinking by associating flavor with open crumb.)

Thanks for the tips Benny! I appreciate having some new ideas to incorporate into this bread.

I don’t associate a loaf with more open crumb with one that has better flavour than one with a more even crumb assuming both are fermented the same. In fact the one with more even crumb might have more flavour per bite. You should do an experiment and see for yourself. Make a dough, divide it in two give both identical treatment with respect to fermentation but just give the one dough more folds than the other then compare them when baked and see if there is a difference in flavour. Again, if the fermentation is the same the flavour will be the same regardless of crumb. Perhaps you are associating poor flavour with underfermented dough which is dense.

You’re right of course, T85 isn’t whole wheat, T150 would be whole wheat.

Benny

For the most part, my baking fails have tasted quite good. I think I'm far more likely to overproof rather than underproof. I'm also quite fortunate to live in an area of the world that is rich in quality mills that use grain from local farms. So all my bakes have high quality flour, and I rarely bake anything that goes straight to compost. I have a >95% whole wheat pan bread that I'm working on that frequently has issues with crumb and overproofing, yet the loaf always has an outstanding flavor.

If I understand correctly, the flavor of sourdough comes from trapped gas, so it would seem to make sense that you should get just as good flavor from a more even crumb as opposed to a more open crumb. (Assuming you don't degas too much while shaping.)

When it comes to high extraction flours, is it reasonable to divide the number by 150 to get the proportion of whole grain? That is, is the ratio of T85 flour that is whole grain 17/30?

Yes some of the flavor of bread comes of the gases produced during fermentation but certainly not all the flavor.

Here is a section from Daniel Leader’s book on European flours you might find interesting or confusing.

European Flours from Living Bread ~ Daniel Leader

Flour in France

The same straightforward system of flour classification is used throughout France. Flour is assigned a number that corresponds to its ash content in milligrams per 10 grams flour. Because minerals are concentrated in the bran of the wheat kernel, ash content corresponds with color. Darker flours have a higher ash content than lighter flours, which have had more bran extracted during milling.

FRENCH FLOUR TYPE

ASH CONTENT

Type 45

Less than 0.50 %

Type 55

0.50 to 0.60%

Type 65

0.62 to 0.75%

Type 80

0.75 to 0.90%

Type 110

1.00 to 1.20%

Type 150

More than 1.40%

Type 110

1.00 to 1.20%

Type 150

More than 1.40%

Type 55 is the standard hard-wheat white flour for baking, including puff pastries (pâte feuilletée). Type 45 is often called pastry flour, and is a finer extraction flour (this corresponds to what older French texts call farine de gruau). Some recipes use Type 45 for croissants although many French bakers use Type 55 or a combination of Types 45 and 55. Types 65, 80, and 110 are stronger bread flours of increasing darkness, and Type 150 is a whole wheat flour.

German Flour

A similar system of classification is used in Germany as in France, where numbers are assigned to flour types depending on ash content. The numbers are different, but still coordinating with ash content:

FRENCH FLOUR TYPE

GERMAN FLOUR TYPE

ASH CONTENT

USES

Type 45

Type 405

Less than 0.50%

Typically used in baguettes, croissants, and soft white breads

Type 55

Type 550

0.50% to 0.60%

Slightly stronger than Type 405, used similarly in wheat bread

Type 65

0.62% to 0.75%

Type 80

Type 812

0.75% to 0.90%

Used in darker wheat and mixed grain breads

Type 110

Type 1050

1.00% to 1.20%

High protein content and strong flavor, ideal for mixed grain and other hearty breads

Type 1600

1.50%+

An even darker color and has the highest mineral content among wheat flours except for whole wheat; suitable for dark mixed bread and for hearty, rustic wheat bread

Type 150

Type 1700

1.50%+

Whole wheat flour

Type 550 is comparable to American all-purpose flour. Type 405 is the equivalent of American pastry flour. Types 812 and 1050 are bread flours of increasing strength. Type 1600 is almost 100 percent whole wheat flour.

Rye in several forms is so extensively used in Germany that German millers have developed a separate classification for rye flours.

GERMAN RYE FLOUR

ASH CONTENT

CHARACTERISTICS

Type 815

0.815%

Finely ground white, the lightest and finest rye flour; suitable for light rye bread, more common in southern Germany than in the north

Type 997

0.997% to 1.09%

Light rye flour with some bran, suitable for mixed grain breads

Type 1150

1.15%

Medium to dark rye flour, good for mixed-grain and sourdough breads

Type 1370

1.37%

Medium to dark rye flour, very flavorful and especially good for 100% rye breads

Type 1740

1.18%

Medium-ground whole rye flour, used for hearty rye and mixed grain breads but also for gingerbread and fruit bread

Type 1800

1.37%

Coarsely ground whole rye, strongly flavored and used in traditional German seeded whole rye breads

The Complicated Case of Italian Flour

In the U.S., flour is classified primarily by its protein content. In Italy, the story is more subtle and more complicated.

First of all, most Italian mills do double duty, selling flour to pasta makers as well as bakers. Flours milled from hard wheat are labelled grano duro. Flours milled from softer wheat are labeled grano tenero, meaning “tender grain.” Mills blend these two wheat varieties based on the type of flour required.

Italian mills market their baking flours according to two systems of classification. The first is based on grind, ranging from fine to coarse. Numbers range from Tipo 00 to Tipo 2 and are obtained by measuring the quantity of flour in kilograms after milling 100 kg of wheat. The higher the number, the coarser the flour. Tipo 00 is ground as fine as talcum powder, Tipo 0 is less finely ground, and so on. These numbers also indicate the ash content and extraction rate of flour. Tipo 00 has maximum ash of 0.5 percent. The most highly processed of Italian flours, it has an extraction rate of just 50 percent. Tipo 0 can have an ash content of 0.51 to 0.65 percent, and an extraction rate of 72 percent. Tipo 1 has an ash content of 0.66 to 0.80 percent. And Tipo 2, with an ash content of 0.81 to 95 percent and an extraction rate of 95 percent, is almost whole wheat.

The most common misconceptions in the U.S. about Tipo 00 flour are that the classification has something to do with the flour’s protein content and that it is the indication that a flour is good for pizza. Neither of these is true. In fact, Italian millers grind grain of varying protein levels into this extra-fine flour, for a variety of baked goods, from the most tender shortbread cookies to the chewiest artisan breads. Molino Grassi in Parma, for example, sells five types of white flour with the designation “00,” with protein contents ranging from 10.5 to 14 percent.

Because protein content is not necessarily an indicator of gluten quality, Italian bakers also rely on an alvéograph assessment before choosing a flour. The essential number for Italian bakers, along with “Tipo,” is a flour’s “W” value, which indicates the relationship between a dough’s rising power (strength) and its extensibility and elasticity. Generally, Italian mills recommend the following W value flours for the corresponding uses.

W VALUE

CHARACTERISTICS

<120

Poor-quality flours, unusable for bread making

120 to 160

Weak flours, appropriate for the production of biscotti

160 to 250

Medium or average strength flours, used for soft doughs (paste molli) in the production of Pugliese, ciabatta, Francese, pane piuma, etc.; for firm doughs (paste dure) in the production of pane ferrarese,and also for the refreshment of natural yeast (lievito naturale)

250 to 310

Flours of strength obtained from high-quality national wheat and strong wheat of national or foreign origin, used in the production of maggiolino, baguette, rosetta, soffiato, and biove

310 to 320

Flours extracted from strong wheat, used primarily for doughs with a long fermentation; indirect method doughs employing a biga or lieviti (natural yeasts) with long rises; or for sweet raised doughs such as pandoro, panettone, Veneziane, etc.

This is very helpful.

Mr. Leader talks of misconception yet he is subject to it!

poor fellow!

Only qualified millers can solve the issue!

Still it is good you posted this Benny, thanks.

You know a lot in this particular area Michael, I’d love to know, if it isn’t too much trouble, what parts of Daniel Leader’s post isn’t correct.

Benny

Hi Benny,

If I may?

This is either a misunderstanding born of conflating two concepts or simply an unfortunate choice of wording that results in the same!

Without getting all Latin (I don't CARE where Caecilius and Matella 'est in'!*) there are two relevant species in the wheat genus: 'common wheat' and 'durum wheat'. So far as we care, durum is durum is durum. On the side of common wheat, there are many varieties that concern us.

Broken down, these these varieties of 'common wheat' are classified broadly as either 'hard' or 'soft'. This level of 'hardness' relates directly to the gluten content of the wheat because it is the protein in the endosperm that matters (and the protein in the endosperm is gluten-forming, unlike that of the bran and germ fractions).

Why does this matter?

Ignoring the utility for food production, it matters to the grower as it is this level hardness/strength in the structure of the the endosperm that governs how readily water is absorbed and is able to reach the germ and allow . . . germination! This is a reason why 'winter wheat' is harder than spring wheat. It's not that there is some specific wheat that is 'winter' wheat or 'spring' wheat so much as the HARDNESS (i.e. protein content of the endosperm) is a requirement for a wheat that will survive through winter. There are other factors of course but it's not really greatly different to what you see with certain species of fruit, such as apples, some varieties of which require more or less 'chill hours' and are thus suited to different climates and will fruit at different times, as seasonal cues dictate.

It also matters to the miller as, generally speaking, they are grinding the endosperm and the harder the endosperm, the harder a wheat berry - of whichever species - is to grind. (Incidentally, this is one reason why higher protein wheats absorb more moisture as the increased force required to grind the harder endosperm also results in more starch damage and damaged starch absorbs significantly more water than undamaged starch. It's also easier for the enzymes to work on, facilitating the break down into maltose for the yeast to then convert into glucose.)

ANYWAY, I digress (as is routine for me).

Just as some breeds of horses are larger or smaller (or faster or slower or black or chestnut,) so too are some varieties of common wheat harder or softer. Common wheat and durum wheat share the same relationship as horses and donkeys. (The analogy works passably well as we tend to care immensely about horse breeds but donkeys are just . . . donkeys.)

I said I wouldn't get into latin but, of course, 'durum' is exactly that and here is where the real confusion comes in: 'durum' is latin for hard. The name is apt as the endosperm of 'durum wheat' (which, again, is what matters) is indeed harder, in general, than 'common wheat'.

But, as with our horse/donkey comparison, it's a generalisation and not and absolute: there is of course a general size difference between horses and donkeys but there are horse breeds barely 3ft high and donkey breeds that, at 5'8" are taller than the average horse. Just so with wheat: there are softer durum wheat varieties and there are varieties of common wheat harder than durum wheat.

That said, the generalisation holds and this was (and still is) especially true in the 'old world', where wheat (as a genus) originated. There, the common wheat that grows are generally of the softer varieties and it was not, really, until wheat was brought to the 'new world' that the rather different conditions led to the much harder varieties being developed.

Thus, in Europe, 'durum wheat' was notable for being hard, relative to the 'common wheat' available in the region at the time and was therefore named for that property.

So there are two types of 'hard wheat' here: 'durum wheat', which is considered 'hard' as an entire species and hard varieties of the separate 'common wheat' species.

And this is what Mr. Leader is either conflating or, at best, explaining very poorly. It has been said that to write clearly, you must first think clearly and it seems that, on this point, his thoughts were, to be charitable, unclear. (So that I, at least, am clear, I claim to no great grasp of clarity and long ago abandoned all pretenses of concision.)

Now, Italian millers ABSOLUTELY mix in harder and softer wheat but when they do so they are mixing in harder and softer varieties of the 'common wheat' species (with the harder ones coming from the US, Canada or even Australia - yay us!). What they are not doing is mixing grain from both the 'common wheat' species and 'durum wheat' species, which is what the sentence strongly implies, if not outright asserts. Think of it like making an apple pie with both Granny Smiths and Cripps apples - so as to get an appropriate blend.

On to the next . . .

Now, here he is not quite so incorrect as he is in the previous paragraph, such that it could just be a (really) poor wording and he is thus doing the reader a disservice rather than propogating misinformation.

Tipo '00' may indeed be marketed as finer ground but that is, so far as the classification is concerned, irrelevant. Where a difference in fineness of grind exists between (for example) '00' and '1' flour, that is either a side-effect or something that is simply easier to do with '00' than '1'.

That's because what matters is the ash content and the ash content tells us how much bran (and germ) is included. The bran is harder and so any flour with bran in it will be harder to mill to finer consistency (requiring more specialised and thus more expensive equipment). Thus, if you want to offer finer flour - for whatever reason - the easiest way to do that is with the 'purest' fraction, which will neccessarily contain the lowest ash and thus fall under the '00' classification.

What that means is that, all else being equal, Tipo '1' will tend to have particles of a larger size (i.e. the bits of bran) than will Tipo '00', which has (effectively) no bran.

But, of course, all else is not equal, or at least not always and there can be Tipo '1' flours that are finer than Tipo '00' flours.

Possibly the simplest way to look at it is that 'type' number indicates how fine a flour is (easily) able to be milled but not how fine it must be milled.

Again, it's a conflation but seems to stem from a misunderstanding on Mr. Leader's part, as indicated when he says:

This implies that the ash content is somehow secondary when, in fact, it is the PRIMARY concern of the (legal) specification. (Other technicalities like the moisture content are in the spec, as is the minimum protein content but, really, I would suggest that those details are, first, to ensure all flour is measured on equal terms and, for the protein, simply to ensure consumers aren't being sold an inferior an ill-suited product.)

To be complete and fair, the relevant Italian law is from 2001, so it is possible that Mr. Leader is reprinting information he gathered for earlier works, prior to the passing of this law and that his information was correct at that time. His only published book pre-dating this was his 'Bread Alone', from 1993 and, while I don't own the book, the synopsis does say that it "chronicles his crossings of America and Europe" so one can suppose that he learned the above information at that time, prior to the new law of 2001 and is simply reprinting that.

However . . . two problems arise: first, the law of 2001 replaced an earlier law of 1963 (revised 1972) and I do not know what this law states. Second: reusing old information from more than two decades earlier without checking to see if it is still valid is not a good look.

So there it is. Phew. (And sorry to all, especially any who made it to the end.)

* - Anyone who was forced to study Latin at school will know what I'm foaming about.

Very helpful, thank you both Dan and Michael. This is an area that I have never spent anytime reading about. I haven’t used any Italian flours other than semola rimacinata so clarifying and correcting the information in Daniel’s posts is very helpful.

Benny

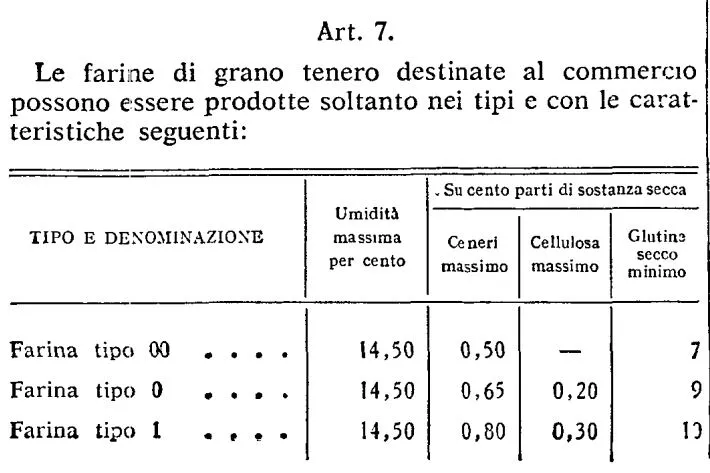

Even in 1993, Leader would have been wrong as the 1967 law states:

Image

The document also outlines, in text, the characteristics of tipo 2 and 'integrale'.

It seems that the main differences in the specifications are the removal of the maximum cellulose and a change in the protein measurement from 'minimum dry gluten' in the original 1967 law to 'minimum protein' in the revised 2001 law, the latter having specifications on 9, 11 and 12% minimum protein for tipo 00, 0 and 1 respectively.

The ash content limits, however, are identical and, as with the 2001 law, there is no mention of the fineness of grind, except as follows (which is the same in both laws):

Remembering that the law dictates that only the listed 'types' are permissible, the above says, simply, that type/tipo 00 flour can also be produced in granular form (which is termed 'granito', translating as 'granite'.) And, again, this is the same in both the 1967 and 2001 laws and is the only mention of particle size pertaining to 'grano tenero' flours.

The section on 'grano duro' (durum wheat flours) does talk about teh size but only in so far as is neccessary to differentiate between semolina (i.e. the coarser granules 'with a sharp edge') and 'durum wheat flour', being the fine product generally known as semola rimacinata.

So, Mr Leader's information, is by at least 42 years.

d

"First of all, most Italian mills do double duty, selling flour to pasta makers as well as bakers. Flours milled from hard wheat are labelled grano duro. Flours milled from softer wheat are labeled grano tenero, meaning “tender grain.” Mills blend these two wheat varieties based on the type of flour required."

As discussed in other recent threads, grano duro = durum wheat, grano tenero = non durum wheat. It would have been helpful if Leader had made it clear that these are two different wheat varieties, triticum turgidum durum and triticum aestivum.

I think it is unlikely that Italian mills sell blends of grano duro and tenero as a matter of course in the way Leader describes.

Lance

That’s really good to know Lance, thanks for clarifying it.

Benny

Hi Lance,

On a technicality, Durum is a different species, which is the level above a 'variety'.

Because I love analogies (and animals,) you can think of 'common wheat' as a dog and 'durum wheat' as a wolf. Wheat varieties are then the different sub-species - in domestic animals like dogs, the term 'breed' is common. (In botany, it's vairety or cultivar.)

So Red Fife is a Doberman and Lancer is a Labrador or whatever. Neither of them are wolves.

There are different varieties of durum, of course, just as there are different varieties (sub-species) of wolves, but the differences between two wolf 'varieties' is not super imporant to people as there will either be wolves near them or there wont; it doesn't much matter to people what type of wolf that might be. The difference between dog breeds is not only much more important but also much more varied because we humans have been selectively breeding dogs to specialise them for a long time. It's the same with wheat - as the significantly more important species to humankind, we have spent a large amount of resources creating new varieties of 'common wheat' to suit our various needs; 'durum wheat' on the other hand is less specialised.

The main gas that inflates the dough is CO2, and it has no taste (well, when dissolved it's slightly acidic, but nothing compared to other acids produced during fermentation, and it's not really retained during baking anyway - solubility of gases drops quickly with increased temperature - the reason why corral reefs are dying due to climate change, btw).

The main flavour compounds are organic acids, primarily lactic and acetic. They are not gases at room temperature, and moreover their boiling points are above 100°C, so they are still liquid when the bread is baked. There is also a not insignificant amount of ethanol produced, which actually boils at 78°C, so would (mostly) evaporate by end of baking.

The flavour does not come from gases. But the gas production can be an indicator of how much fermentation progressed, and hence can correlate with final flavour - but the structure of the crumb definitely has no direct relationship with taste. The eating experience is different, of course, so I'm not saying it doesn't matter :)

Thanks for expanding on this Ilya.

So my belief that degassing dough degrades flavor is incorrect? Is shaping and trapping gas more for aesthetic purposes? That is, can a "poorly shaped" loaf taste as good as a "well shaped" loaf?

I love baking. The more I learn, the more I realize how much I don't know!

I know that Chad Robertson has written that the gases do have flavour components in them, at least that is my recollection. But as Ilya points out CO2 is the major gaseous byproduct of fermentation and it is flavour less. I think that degassing will mostly have an effect on the texture of bread. Certain grains may be of milder flavour, so if baked with a super open crumb may have less perceived flavour, that makes a bit of sense to me.

I did get this idea from Chad Robertson's Tartine book.

Trevor J. Wilson's videos also leave me with the impression that you don't want to degas. I don't recall if he says this has to do with flavor, or just to open up the crumb.

I think most bakers do not want to degas excessively because it will tighten the crumb.

As Ilya points out, from a purely chemical perspective, CO2, will acidify any water it is dissolved in (think carbonated water, which is actually rather acidic).

I suppose it is possible that degassing would cause some of the trapped carbon dioxide to dissolve into the water in the dough but whether it does or not would depend on the whether there is sufficient free water for this to occur and/or whether this is possible with bound water. Even then, as Ilya again points out, the effect is likely to be small and thus insignificant compared to other processes.

There is another process that is impacted by acidity, which is the action of the amylase enzymes. The big job of these in bread making is to catalyse the reaction that breaks long starch molecules to produce maltose, which can then be further converted into glucose by the yeast and consumed.

Now, here you have the very two people who know about this - Benny is the master of pH and Ilya knows her enzymes, and their interaction with pH levels through her virtuosity with rye.

I will try, however, to make the best of it I can.

The amylases free sugars and, the more sugars so freed, the more there may be left over (i.e. that the yeast doesn't have time to finish eating!) and thus the more there will be to contribute both to sweetening the bread and caramelising the crust. (This is why 'malted flours' produce a darker crust - the malted barley that is added to make malted flour contains elevated levels of amylase enzymes which means more sugars are freed.)

The salient point is that amylase works better at more neutral pH levels and worse at lower (i.e. more acidic) pH levels. Thus, anything that contributes to lowering the pH will contribute to a reduction in amylase activity and thus a reduction in generation of sugars.

How much and whether that really matters is unknown and, again, it would depend on whether the act of degassing does actually cause some of the carbon dioxide to dissolve into the dough.

Which is all to say that I can see a possible mechanism for degassing affected flavour, though it would be indirect, of questionable magnitude and contingent on several factors I can't speak to.

Definitive, no?

d.

Pretty sure the dough is saturated in regard to dissolved CO2 anyway, and no kind of handling would change that.

I'd say likely the bubbles in the dough can only significantly grow after the concentration of CO2 reaches saturation in the liquid phase, so it's certainly saturated soon after the start of bulk fermentation.

If I understand correctly, this is why we autolyse?

Adding starter lowers the pH of the dough. So if we mix flour and water before adding starter, this gives the amylase enzymes more time to produce maltose?

That's almost incidental but I did actually experiment with this a few times and I think I noticed a difference in sweetness, overall, when I did an overnight cold autolyse. HOWEVER, our flours in Australia are not malted so I was trying to give it a natural boost in that fashion. More rigorous tests are likely called for here : )

But, while it is something that occurs during the autolyse, it is not the reason for it.

I have written at some length on this topic (this should not surprise anyone by this point) and I'll throw in a link if I find it but the autolyse was promoted in order to reduce the required mixing time.

You will have seen this - when you autolyse, you spend a minute (max) mixing and then, when you come back to the dough after however long, it will look like a much smoother and more homogenous mix.

Again, while many other processes are occuring as soon as flour and water are mixed, the benefit of reduced mixed is the key reason as the problem for which a solution was sought was what happens to a dough when it is mixed too long - especially in a commercial mixer: oxidisation.

In short, mixing oxidises the dough and this degrades the cartenoids (think beta carotene, which gives carrots their colour). This 'bleaches' the flour, which may or may not be deisreable, but also reduces the flavour these compounts are able to contribute.

So, the less mixing, the less oxidisation and the lower the negative effect of flavour and colour.

Here's the link to the aforementioned post. It contains my usual level of verbiage. You have been warned.

https://www.thefreshloaf.com/comment/492039#comment-492039

Dan.

Most of the flour I get is not malted. I just had a look in my kitchen, and the only malted flour I have is KA bread flour. The majority of the flour I use is local, so it won't be a good representation of what is found in a typical North American supermarket.

This may be why I am able to get away with long autolyses. I frequently do a two hour autolyse with my rustic loaf made with T85 flour, and I often do a four hour autolyse on my whole wheat pan loaf.

Now that I think about it, this may be why I have troubles with my whole wheat loaf. It's a very coarse flour, but I often get a gummy crumb with tunneling. (I'm sure misreading fermentation contributes to this as well.)

If you’re going to do such long autolyses you might want to consider adding salt to your autolyse, call it a saltolyse. I have done this quite a bit and it works well as the salt slows the action of the amylase somewhat. Also if you refrigerate the dough during the saltolyse that also helps slow the amylase. Although your flour may not have amylase added to it, it will have the naturally occurring amylase so doing such a long autolyse may not be beneficial and maybe detrimental.

My own experience (which is not a patch on Benny's) tells me that I can do a 2 hour, moderate temp (~18C) autolyse with no ill effects noticed.

That was with unmalted, mid-protein (11.5%) Aussie flour. The same flour has also survived an overnight fridge autolyse with no (observable) deleterous effects.

Neither had salt included.

I would say, however, that I don't necessarily see much point going beyond 2 hours at room temp in the first place so there's no real cause for a 'saltolyse'. Keep it to two hours max on the bench or, for scheduling purposes or to soften particularly coarse particles, mix, cover and refrigerate until the next day. (Or do it in the morning and take it out at night as suits.)

If you find yourself ever considering adding salt to an autolyse step then I think you need to ask why.

To my mind, there are only two (good) reasons:

What Benny says is absolutely true - salt will slow enzyme activity during the autolyse. The follow-up, however, is to find out why you are looking for an autolyse so long that this becomes and issue (with unmalted flour).

d

I think the idea of overnight cold saltolyse was originally for whole wheat: full of enzymes that would otherwise degrade the flour, hence salt and cold, but long time to form the gluten and soften the bran.

That makes sense - more enzymes to reign in. I suppose it depends on what 'overnight' means for people. I tend to only get around 6h sleep most nights (and not infrequently less) so I suppose I don't view 'overnight' as an overly long time!!

d

This is definitely true, but also out of convenience so that an overnight levain build could be done and to autolyse the dough without having to wake up in the middle of the night to start the autolyze.

I just made a loaf of whole wheat bread where I accidentally added salt to the autolyse. (I made a lot of enriched doughs this week so I was going on autopilot. I usually mix the flour and salt with enriched dougs.)

I will start keeping my autolyse to about 2 hours. I use a low percentage of prefermented flour on my whole wheat bread so that I usually get about 8 hours of total time fermenting. It sounds like a long ferment gives the enzymes enough time to work their magic?

Yes, it will.

Enzymes, unlike yeast, do not multiply. The upshot of that is that they work at a more-or-less linear rate. Flour contains some smallish quantity of free sugar as it is so this is what the yeast start on while the amylas gets to work. I think wheat flour contains ~2% free sugars at the get go, with wholemeal a bit higher.

Remember, though, as Benny said: amylases are present in wheat flour anyway - adding malted barley just boosts that.

The enzymes in wheat are activated with water* and then are able to start breaking things down. This is what 'germination' is - the wheat kernel gets water inside it (after rain) and this sets the various processes going that break it all down and provide fuel for the germ to activate and start growing. (This is why you dry seeds you wish to keep for next season - so that any moisture in them that might start those reactions is removed.)

The 'germ' is the growning baby wheat - like a growing chicken embryo in an egg - and the endosperm layer around it is its food for growing, as the egg white is in chickens. Again, as with chickens, the outer layer is the protection.

Roughly speaking, of course!

The point is that the wheat kernel itself contains these compontents because, in nature, they are require for propogation of the plant.

d

* - This is not strictly true. Enzymes are catalysts and, as such they 'assist' other reactions, making them easier. In some cases, the reactions they assist with are so 'difficult' that they would not be possible otherwise, or would require prohibitive amounts of energy or time. In the case of wheat flour, the breakdown of starch (amylose and amylopectin) is via hydrolysis, where a water molecule 'breaks' the bond between adjacent glucose molecues, which are what makes up starch. Amylase (so named because it works on amylose) kind of pushes the water into the reaction and thus greatly increases the rate at which these reactions occur. As such, the water molecule is consumed but the amylase is not and, after the reaction is complete, it finds another water molecule to press into service.