Inspired by Benny's red fife bakes, and an earlier red fife by @suminandi that caught my eye, I wanted to see what I could learn from working with this flavorful but fermentation intolerant heritage grain. I'll be doing a few bakes with this one using desem at different percentages of PFF.

Based on Benny's baking notes and comments from others, I erred on the side of caution in this one, and it might be a little underfermented.

Details to follow.

Update:

- 20% PFF

- hydration by feel in lower 70's

- final pH 4.12 (very sour to taste)

- headupinclouds's Blog

- Log in or register to post comments

Well well well, that is a good looking loaf of whole red fife. It is gorgeously plump and has lovely blisters as well. I can’t wait to see the crumb. Well done especially for your first go at this grain.

Benny

The photo probably paints an overly optimistic picture. The feel of the loaf in my hands suggests it is a little too dense to be a notable whole-grain bake. Actually, this is a do-over from the initial version I mentioned in your thread. I was making the ruisreikaleipa, sourdough pizza, and the red fife on the same day. Needless to say, I don't have the precision timing required to pull this off reliably, and the fermentation schedules ended up colliding. I also had to restart the rye sour. Too much in one day! The initial red fife dough (the one I mentioned was behaving strangely) got away from me while I was shaping and baking the ruisreikaleipa, so I quickly queued up a second one (shown here) after finishing the rye. Something definitely went wrong, so I wanted to simplify the approach. The second time around I just milled and mixed, and kickstarted things with @mariana's food processor mixing trick with a conservative 30 seconds of pulsing to save time, followed by Rubaud. No soaker, no sifting, no bran toast-and-scald with postponed inclusion. That's probably where I should have started. Interestingly, the dough was *much* better this time around. A little bit more fragile than other wheat, but nothing like the first one. Your comment about acid and enzyme attacks got me thinking. From WGB I was under the impression that cold temperatures and salt would protect the dough from enzyme attacks, but now I'm curious if even this is too much for some active freshly milled flour. I can't say for sure the soaker was the culprit (as opposed to milling or treatment of the bran), but it seems like the most plausible explanation to me. It is probably worth a dough strength comparison similar to what Kristen does in her 100% whole wheat video to confirm this. I had planned to bake this on the same day with a warm final proof, but it was only at 25% by the time I was craving sleep, so I stuck it in the fridge in a just below 40 F location and baked it the following morning after measuring a pH of just approximately 4.2. I let it sit on the counter while the oven preheated, but probably should have waited for more of a visible rise before sticking it in the oven. I believe The Bread Builders mentions gluten degrades at 3.9 (need to double check) and mentions a target pH for desem of 4.2, so I'm going to use the latter as a conservative cutoff for these whole grain red fife bakes. I *think* bumping the % PFF is one tool we can use to achieve the same (or higher) level of proof for a given pH cutoff, but have no confidence in application of this theory. It will be interesting to see if this helps things. I was also curious about exploiting discrepancies in yeast and LAB lag cycles as outlined in GeorgeQ's discussion w/ Debra and others in his 100% spelt loaf post. I'd like to make better use of the pH meter, since it is one of the few things we can measure, and if your acid/enzyme theory is correct, this would be a good loaf to learn from with it.

The addition of salt for saltolyse is for me mainly to slow down amylase action. Because there is no levain in there yet to acidify the dough I’m not yet worried about protease actions. You’ll recall protease enzymes in the flour are activated when the pH fall to < 4. So the gluten shouldn’t be degrading very early on at all. Knowing this I really should have consider following pH as the guide to when to end bulk and shape and when to bake. I know some bakers have collected data that suggest that shaping done at pH around 4.4 and baking when pH is 4.1 is quite ideal. That 4.1 would make sense since it is above the pH where proteases are yet activated.

Benny

Thanks for your input and precision. I would love to see your pH experiments with this grain. It seems amylase reactions and starch damage would be the culprit in the first dough. I recall some discussions suggesting there isn't quite enough salt in a standard formula to halt such reactions entirely, so perhaps it could still be a point of concern. This leads to the first question.

Are there adverse reactions that can still occur in hydrated freshly milled whole grain flour assuming standard 2% (bakers percentage) salt levels and cold (< 40 F) storage for periods less than 12 hours?

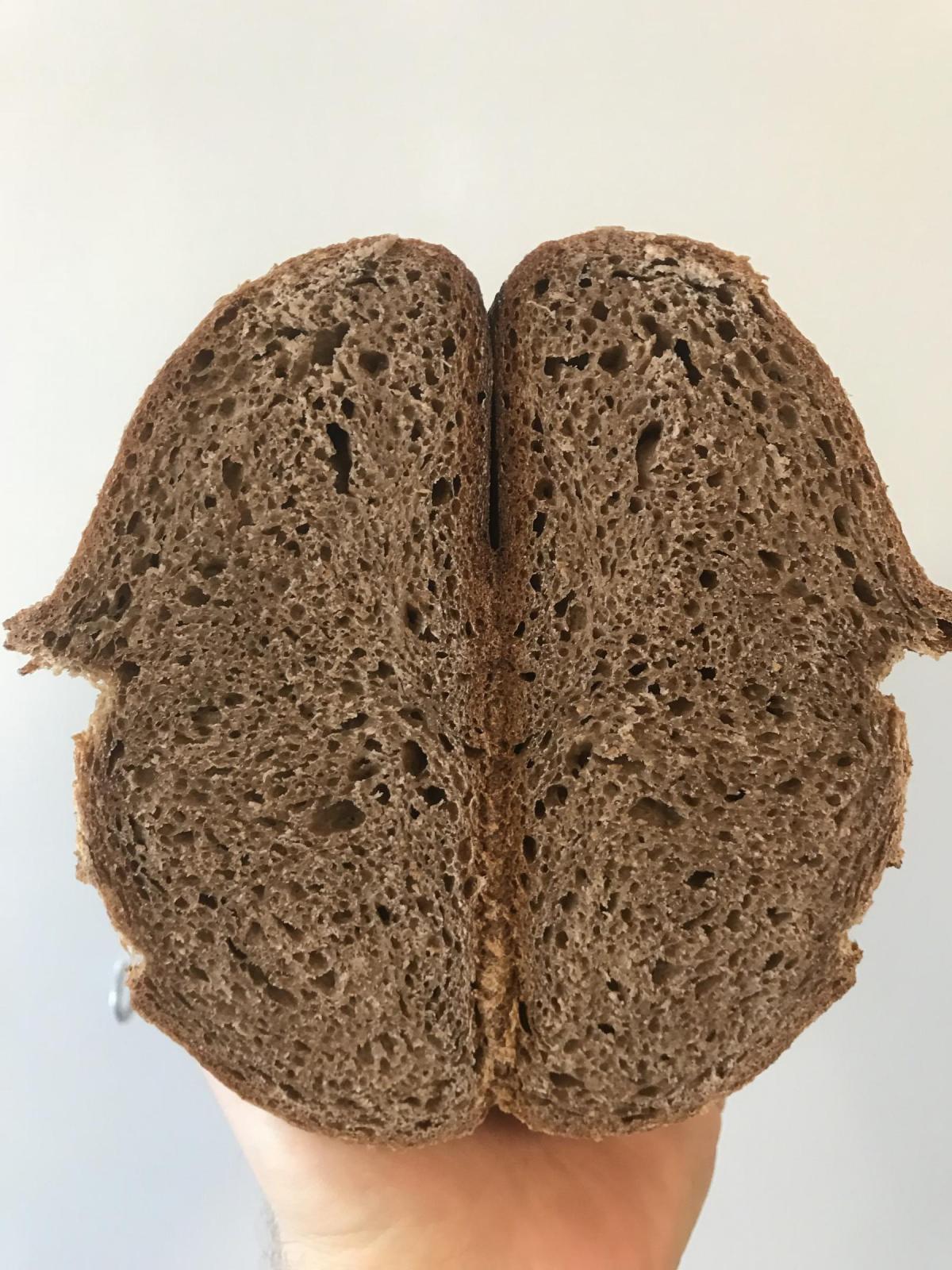

I've updated the post with a crumb photo. It is fairly dense as expected and sourer than I would like. I'm going to try another one with a higher % PFF and a same-day warm or room temperature final proof terminated at a higher final pH. I don't yet know what final dough pH to target for a target final bread pH, but presumably, some allowance needs to be built in for the increasing temperatures early in the bake combined with dough at a very active period. I think running the final proof at a cool (but not cold) temperature might also be helpful in this case, as in Kristen's 100% whole wheat video, although I haven't experimented much with that. My understanding is that cooler temperatures should be favorable to the yeast, but longer fermentation times at lower temperatures could potentially reduce any advantages from yeast and LAB lag cycles. I'm hoping to use these bakes and this forum to make this all a little less abstract. It is a complex optimization process that I don't have models for. This leads to a second question.

For a given flour and target hydration and a small amount of starter, What schedule of temperatures and feeds will achieve the highest pH for a final rise of 2X (or 1.5X, etc)? (I'm not implying that goal is always desirable, but it helps simplify the problem.)

The answer will, no doubt, vary according to the starter and grain, but I would be curious to see a working model for any starter and flour to help clarify these tradeoffs.

I don’t have answers for either of your bonded questions, however, I wanted to say that your crumb is quite nice and better than my 5th and most recent bake. My only more open crumb happened with I grossly overproofed the dough but then was able to get more open crumb.

I’ve forgotten what I may have said but wanted to also add that I did a flour stress test on the weekend because I bought a better quality bag of white flour and wanted to compare it to my current bread flour, 10% protein flour and whole red fife. So I mixed each at 80% hydration and after 90 min of autolyse, compared the quality of the gluten at that hydration. Amazingly my new flour which is an organic all purpose but said to have over 12% protein had better gluten strength and extensibility than my bread flour at 13%+ protein. Not surprisingly the 10% protein flour didn’t fair well but the whole red fife faired poorly as well. This leads me to think that 80% hydration is definitely too high for this flour. I’d have to test it more but if I were to try another 100% loaf of red fife I’d want to be higher than 75% but less than 80%.

I found this post and comments very helpful. I really like this variety of wheat and want to like it more, but wow, my first attempts really tested my expectations. I did not truly understand the implications of a wheat commonly described as fermentation intolerant until the surface started tearing halfway through the bulk. What the heck! Gentle hands and whispered curses eventually turned out a flat, but wonderfully complex loaf. Even though I home-milled the flour right before mixing, these loaves started out so strong I thought I was going to nail it on my first go! The coiling felt beautiful and shape was holding very well until the second half of the bulk.

I typically inoculate at 15%, and bulk at room temp taking dough temp readings after every stage. I shoot for 75F and can usually maintain that in the Summer months. From inoculation to retardation, I'm usually performing the final shape and getting them in a 36F fridge in about 4.5 hours. These guys simply began to fall apart half halfway through-- completely lost their pre-shaping and exhibited tearing on the surface. Caveat: I do an overnight salted autolyse at room temp. I want that amylase! I like my loaves dark and complex. Because of the visible surface tearing, I thought I was dealing with a runaway protease problem chomping away the gluten mesh I had worked so hard to align. But from what I have read here, it should not have been an issue because the PH during the autolyse would not have kicked those little buggers into gear.

So, does it follow that the real gluten-chomping proteolytic activity happens within the LABs instead of on the surface of the wheat? I had hoped that incorporating some sort of mild, natural protease inhibitor such as legume flour-- chickpea, red kidney, buckwheat, possibly soy-- after autolyse and before inoculation might mitigate the outright slaughter of my gluten mesh down the road. Would a such an inhibitor make any difference at any stage in the process? Or am I simply chasing the wrong rabbit down the wrong hole by clinging to my assumptions about protease-cum-culprit based on my observations. I would know the thoughts of those of you who have worked with this lovely and challenging variety.

My understanding is that the primary proteases that affect our doughs are from the grains. I’m sure that LAB have proteases within their cell walls but I have never read that they had any external effect, ie they are not secreted. I have never been able to find any explanation for red fife’s fermentation intolerance so I have just come to my own conclusion that it likely has higher protease levels than most other grains. Thus when the pH gets below 4.5 and peaking at 4.0 the proteases start their work of breaking down the gluten.

My experience with 100% whole red fife sourdoughs mirrored yours in that the dough starts out after the long saltolyse feeling very strong and well developed only to end up overproofed when baked.

Benny

Hi Benito,

I've have followed your particular blog here for a bit. Your intensive exercises with Red Fife fascinated me and contributed heavily to my decision to pull the trigger on the 50lb bag I've been playing with. After reading through your trials and victories with the big Red, I have have achieved a true and lasting peace with a 25/75 blend of patent/wholemeal (wholemeal blend predominantly Red Fife), though I still dream of a 100% loaf that actually resembles a loaf! Isis, grant me patience! I have not baked at the same pace I did last year, so I feel quite jealous of what kitchen laboratory time I can steal these days. But I will continue to lurk this site, keeping a keen eye out for more insight into this tricky variety. I think I will try adding about 5% chickpea flour on my next go. Still so curious if this would indeed inhibit protease activity enough to produce an observable change in the late stage rheology. At around 6.4 PH-- just below neutral-- I *think* I can rule out the chickpea buffering general dough acidity and introducing a new variable to consider. I'll report out when the I get back in the lab. Thanks for your comment!

You mention pH 6.4, is that the pH of the dough when you add chickpea flour or is that the pH of chickpea flour mixed with water? I would be interested to know what the buffering ability of chickpea flour is? pH of the dough without chickpea and with chickpea flour.

I’ve been thinking about what to try next with 100% whole red fife with the stash I currently have left which might just be enough for one loaf. I’ve been considering using Yeast Water and some sourdough or a hybrid IDY and sourdough both in the hopes of reducing acid and reducing gluten degradation. Unfortunately when I was going through my 100% red fife phase I didn’t have a good pH monitor, because it would have been good to know the pH readings at the end of bulk that those bakes had.

Yes, I meant 6.4 for just the chickpea flour. I just Googled chickpea flour ph and went with the first hit of 6.36 to 6.48. Though I have some concerns about my assumptions and my current approach to this challenge, I keep circling back to this thought experiment:

I wonder if by adding the relatively neutral PH chickpea four to the dough, during or post-saltolyse, would overall dough PH raise significantly enough measure with consumer-grade PH testing.

I like the taste of sour, and appreciate the other benefits of acidity in bread-- preservation, bound mineral freedom, etc.. I would not wish to raise the PH of my loaf significantly, though high-percentage wholemeal breads seems to roll with the punches and keep some tang even with fairly alkaline enriched dough additions.

Correction:

What I wrote:

What I meant to write:

During the baguette community bake last summer there were some bakers playing around with adding legume flour to their baguettes early on. The idea being that it increased the extensibility of the dough. Ultimately those who tried it weren't enamoured with the flavour added by the legume flour if I recall correctly. I always wondered what the mechanism was for increasing the extensibility.

Oh wow, that peaks my curiosity! I would also like to understand that mechanism. Everything I have read about dough development attributes protease's gluten sheering to extensibility. So odd! Legume flour has been used to treat flour milled from wheat whose gluten potential had been damaged by insect activity by inhibiting protease activity.

Sadly, most of this research remains behind paywalls, and I have mostly just found study abstracts upon which to form assumptions.

This abstract mentions legume flour to address insect damage: wheat: https://www.researchgate.net/publication/283106237_Effects_of_Natural_Protease_Inhibitors_on_High_Protease_Activity_Flours

I found the full text of a paper which addresses natural proteas inhibitors and dough quality:

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6616451/

Take a look at the section with the following text:

For example, proteolytic degradation of gluten will reduce bread loaf volume and product quality. However, incorporation of natural protease inhibitors into such high protease flours can assist in preventing deterioration of gluten quality and enable production of high quality dough.

You might find this table useful. You'll see that wheat grain doesn't contain metal proteases but do contain serine proteases.

I find that table incredibly useful; thanks for sharing it.

Check out this study. You can download the full text:

https://www.researchgate.net/publication/257638026_Serine_protease_inhibitors_in_plants_Nature's_arsenal_crafted_for_insect_predators

It mentions chickpea:

"In chickpea (Cicer arietinum) seeds several Kunitztype isoinhibitors of trypsin are differentially expressed."

and

"Kunitz-type inhibitors form a separate family. Although the members of this family are generally active against serine proteases they also exhibit inhibition against other proteases as well including the aspartic protease..."

Benito, I worry about confirmation bias and my limited understanding of most of this, so I would love your thoughts. Does the idea of using plant-based PIs -- probably in the legume family-- to stabilize late stage dough integrity have legs?

I’m really not sure whether or not using legumes for their protease inhibitors will work or not. I think there are too many moving parts to this question that can only be answered by trying it and finding out.

Benny

Oh another thread just reminded me of another thing to try with red fife, adding a pinch of a crushed Vit C tablet. The Vit C is supposed to strengthen the gluten helping it create more disulfide bonds. This in theory should make it more resilient to proteolysis. I haven’t tried this but it was on my list for the next red fife bake.

Benny

Thanks, Benito,

I'll look for that thread. I may have lurked it already as I have considered using laboratory isolated compounds for this particular challenge. I already have some microbial transglutaminase. You may already know about this enzyme, more widely associated with meat glue, but also used extensively in commercial baking. I've used it for making very pretty turkey roulades with good success. I have a small bag of Activa® RM, which also includes maltodextrin and sodium caseinate.

I have read that transglutaminase encourages protein bond crosslinking, where vitamin C discourages naturally-present glutathione from interfering with crosslinking.

I definitely feel motivated to experiment with incorporating some chickpea flour-- probably 5% max. However, before I do that, I believe my general 100% WW technique could use some tweaking. On my last attempt, I believe I agitated too aggressively. I also used the lamination technique, which I think overstressed the mesh. I hope that Rubaud agitation and gentle coils will convince big Red that I really do want to work together!

I'm on a baking hiatus for these hot months and just noticed this. I had better luck with 100% Red Fife bakes in a follow up effort using my new (at the time) home grown desem starter here. I was feeding close to 5:6:5 prior to the bake with 10% PFF in the final mix and used a shorter bulk fermentation than I was accustomed to prior to retarding. I too had been using an overnight salted autolyse in my standard process, but dropped that to 1.5 hours in these bakes.