Hi, I have been baking sourdough for almost a year and am still learning so much! Apologies for the length of this post but I know you guys need detail when you deal with questions!

I normally follow a Maurizio best sourdough style approach of young levain, warm bulk then overnight cold retard but recently I found a book of recipes from London based bakery Bread Ahead which outlined a pretty much 100% cold fermentation process which takes place over 3 days.

I thought 'this can't possibly work' but the results were pretty tasty, although the crumb was a little dense (although that could be the hydration levels. The advantage primarily is that it's a whole lot more flexible than warm bulk - the dough seems to sit happily in the fridge for ages and still gives a decent rise.

Below: Cold bulked loaf profile

Below: Cold bulked loaf crumb

Below: warm bulked loaf crumb

Ingredients (both loaves, per loaf)

450g extra strong Canadian flour (organic, Marriage's)

30g whole organic rye flour

336g water

9g salt

170g stiff starter, made 24 hours prior from 80g plain flour, 20g water 59g liquid starter (cold bulked loaf)

50g liquid starter - wholegrain + plain flour 100% hydration (warm bulked loaf)

Cold bulk method used

1. Day 1 - Mix flours & salt, water and starter. Knead 8 mn then refrigerate for 24 hrs.

2. Day 2 - Next day, take out and fold - 30 min bench time , then fold again. Pre shape, rest 10 mins then shape and refrigerate again for 15 hrs.

3. Day 3 - Bake in 220C in dutch oven (spritzed with steam) with lid (20mn), then 180C with lid (10mn), then 35 mn at 180C without lid

Warm bulk method used

1. Levain - approx 6 hours at 25C

2. Autolyse 20 mn

3. Mix with levain - rest 10 mn

4. Mix with salt and slap & fold 5 mn

5. 5 stretch & folds - 3 at 15 min intervals then 2 at 30. Total bulk time 4 hrs 30 in Brod & Taylor @ 25C.

6. Pre shape, 20 min bench rest, then shape and cold retard for 14 hrs.

7. Bake same as above.

I have included pics of the two loaves for comparison. I forgot to take one of the warm bulked loaf's profile but it hadn't risen as much and spread more.

My questions to the forum - anyone else had success with this cold bulk method vs the warm bulk and are there any tweaks you can suggest to me to help me improve the crumb?

Also, any ideas from the method above why my warm bulked loaf hadn't risen as much? Is it a touch overproofed?

Thank you, Alex.

Alex -

"6 hr @ 25°C"? I can't tell from that description how well fermented the levain is when you use it.

The way I reconstruct your formula it looks like 18% pre-fermented flour, 67% hydration overall, and ~1.5% salt

For your warm bulked loaf, 4 hrs seems about right if the levain was mature, but 6 hrs at 25°C may not actually be enough to assure that the levain is ready. If you mixed it at 1:1:1, maybe, but without knowing more about the seed starter that you used to initiate the levain it is hard to make a call. I ususally run my levain as 1:6:6 (actually 27:168:168) for 12 hrs @ ~83°F so longer than yours, but also warmer, and I can't tell if the feeding ratio is close. My suspicion is that the levain was immature and a 4 hr bulk was actually not long enough. If you used an aliquot jar to monitor the bulk fermentation you might have a better basis for stopping it at a particular point. Some of us ran a series of experiments to try to determine in some sense the "optimal" amount of volume increase you should seek during bulk and arrived at a range of end points from 20% to 50%. I have found that for a low hydration loaf (as yours is) a little more bulk time can make things easier when you get to divide and shape while at higher hydrations (68-78%) a shorter bulk makes handling easier. Also as the hydration goes up, introducing a retard step to chill the dough improves handling both before divide/shape and again before baking to improve the slash. But you should be in good shape with 67%. The tightness of your crumb suggests that you could use more time in a combination of BF and proof but how you want to divide it up is sort of up to you.

There is also the matter of the exact temperature of your refrigerator where you put the dough. At 39°F, the yeast will pretty much shut down once it really gets to that temperature but the LAB will continue to produce additional acid (slowly). The models for both yeast and LAB growth rates at low temperatures are not very good so it is up to you to iterate your cold time block lengths to get what you need when you take it to the oven. One option is to let it bulk at room temperature longer before you put it in the refrigerator. Figure it will take 2 hrs to get cold all the way to the center.

A difference of a few degrees can make a big difference when your cold bulk and cold proof times are long. Hamelman suggests 42°F for 16 hrs but I have found that there are a lot of undisclosed variables in those numbers so best to figure out what works for you.

You are getting good oven spring and crust color without any diastatic malt (DM) so I would not change anything there. You could increase your salt up to 2% without any impact on overall performance. And your crumb looks like you are developing the gluten adequately, though a low hydration will hide a lot of flaws in mixing and folding.

If you want a more open crumb, there are a number of things you can do:

1. take the rye out until you are successful and then put it back in (slowly) and watch what happens.

2. increase the hydration about 2% at a time and see how your dough handles as you make the change.

3. increase the gluten development by mixing longer and folding more during BF. When the gluten is close to its maximum development you will know it by the fact that you can no longer fold the dough and get it to stick to itself (it wants to form a ball rather than stretch). Increasing hydration will allow you to more fully develop the gluten but it is a narrow path to walk between more extensibility and a dough that is harder to handle.

Consider getting a copy of Open Crumb Mastery (Trevor Wilson) at this link

You are doing very well so take all of this a coaching not criticism, and keep on baking bread.

Doc

Wow lots of super useful information in this response, thanks for taking the time to share it all Doc.

Benny

So true Benny I agree! something very informative, Thank you to the post and thank you Doc!

Carlo

Wow so helpful and encouraging. THANK YOU.

The levain (for the warm bulked loaf) was 17g mature starter + 17g whole wheat + 17g plain + 35g room temp water. When I used it, it looked like it was just starting to fall and seemed ready... perhaps it wasn't quite...

The dough didn't seem as gassy and 'jiggly' as it should have done when I ended the bulk. However, when I took the dough out of the refrigerator the next morning it had exploded right over the banneton and felt 'flabby', like it was over proofed. My refrigerator sits at around 42F

I am going to try your tips this very week. Thank you again for your hugely helpful advice. This is why I love and value this forum. Alex

Your levain build was 1:2:2 @ 25°C which is a little short but not out of bounds (the timing does depend on your starter so if you have an exceptionally fast one it will be different). Think of it as using less levain than you planned. The result is you need a longer bulk fermentation. I would probably let the levain go another 3-6 hrs, but once it is mature it is good for an additional 8 hrs at room temp so don't worry about precise timing.

Strongly suggest you begin using an aliquot jar to actually measure the volume increase during BF. It is a good but not a perfect tool because it is never at the exact same temperature as the bulk dough and you are monitoring an exponential process that is reasonably temperature sensitive so the longer you have to BF the larger the error will be. And focus on consistency rather than precision.

Your refrigerator is warm (warmer than FDA would suggest; I think their guidance is <40°F) so turn it down a notch and check it. The best way to measure average refrigerator temperature is to put a quart of room temperature water in the refrigerator where you will put your dough (because there can be a few degrees of difference top to bottom) and measure the temperature after 12 hrs. The mass will do a nice job of averaging over the time period.

If you are going to leave the temperature at 42°F then you will need to compensate by shortening the proof time. The other thing you can do is to shape early and let the dough get the additional fermentation time at 42°F. Just make sure that the whole process is balanced. There are real benefits to a 42°F proof in that the dough continues to produce CO2 which is largely absorbed by the liquid in the dough (because as it begins to cool the dough goes from saturated to unsaturated with CO2). The result is that when you bake it, the CO2 comes out of solution and strongly contributes to oven spring (and if you have good steam it will give you some surface blisters too).

It is probably more common to go to the oven too soon than it is to overproof. The "jiggly" dough is a good sign that you got there, but if it didn't fall on you, you got a taller loaf than you otherwise would have. So it easy to go to the oven too soon and hard to wait for the dough to be fully proofed, but it is a good experiment/lesson to divide a batch into three parts and bake the first one when you think it is ready. Wait for the first one to be done and the DO reheated, then bake the second one. Repeat for the third loaf. You will be surprised at how conservative you are in deciding when to bake and it should change your behavior.

I would note that if you wait too long and still insist on slashing the loaf, you may induce a crash. So caution is advised. The slash is there to let the dough expand after the surface is cooked, and if you don't slash a loaf that wants to expand, it will just blow out someplace where it is not pretty (usually along the side down where it contacts the baking surface).

CQ, I take your warm/cold crumb shots as a confirmation to my test below. To be sure, artisan bread is a fickle thing...

Just yesterday I ran a comparative test. The only variance was the temperature of each dough during retardation. Like Doc said, 39F will slow down the yeast to the point where the retard can go for 12 hr or more without noticeable dough growth. BUT at 43F the growth is noticeable. My goal is to produce a crumb without large holes. To many, that sounds strange. LOL

Below overnight @ 39F

Below overnight @ 43F

More testing is needed to confirm, but this test indicates that more fermentation rather than less will produce smaller alveoli.

BTW and for what it’s worth, this crumb is my goal to constantly produce.

Danny - can you clarify? Same batch of dough just split for proof? Or same batch of dough split before BF then proofed differently? Or one batch of dough split before BF and one with cold BF and the other run at room temp then retarded for proof.

Doc, the dough was BF together and separated during the divide and shape. The only variance the 2 doughs rec’d were the 4 degrees of difference in the overnight retard. The weighed the same and were handled and shaped identical. One dough @ 39F, the other @ 43F.

BTW - both loaves have the same blisters. The reason they were blistered (I’ve baked for years with no blisters) is because they were shaped and placed in split PVC cylinders with parchment paper - seam side down. The bags were also misted with water. It seems in. My case that bannetons with floured liners absorb too much moisture from the tops of the loaves.

So what do you think happened to the alveoli that became large holes in the 39°F loaf? This deserves some thought.

I think that less fermentation produces larger alveoli. Remember how Benny started fermenting his baguettes to 30% or less and how gorgeous the crumb was. Before that time most of us (seeking super open crumb) were fermenting much more.

There is so much to learn... Ain’t it great!

Chances are this theory is incorrect. LOL

BUT, to that I say, “ There is so much to learn... Ain’t it great!”

I am still looking for the reason why less fermentation produces larger alveoli. While we have a few cases where larger alveoli emerged from dough that spent less time in bulk fermentation, they were not instrumented well enough to ask hypothetical questions about the influence of other factors and then design new experiments. Maybe Benny was just doing his magic without recognizing that he is doing something different from the rest of us. It has happened before.

I would like to know the definitive answer to that question.

when I think about it, I am still reasoning that the yeast activity generated n the very initial stage of the bake is pumping up the dough with gas. But upon learning more, this does not seem to be the case.

I’d bet our buddy Tom Cucuzza has a video dealing with this, but don’t have time right now to investigate.

https://youtube.com/channel/UCvFd727zQvioesPXe3eKkfg

Actually, what was happening at that time in the baguette CB was that I was getting nice crumb but not ears when bulking to 30%. Remember that final proofing then took the baguettes past 30% so the crumb was great but there were no ears. Then after repeating the bakes thinking that it was my shaping etc. I finally decided to reduce bulk and proof. So now I bulk to 20% and proof to 30% max. At this degree of proofing (by aliquot jar) I am able to get the crumb I want and also good ears assuming my shaping is up to snuff. So it wasn’t that my crumb improved when going from 40% to 30% proof, the crumb was about the same, it was the ears that improved.

This doesn’t help the question that is being asked, but I wanted to clarify my recollection of what was happening at that time.

Now, with non baguettes, I am definitely noticing that more fermentation without overproofing does get better crumb in terms of openness. As I have been pushing fermentation and proofing, with a strong dough gradually going higher and higher, I am finding a more open crumb. This doesn’t mean necessarily bigger holes, I don’t want that, but thinner cell walls and less and less areas of any density. I don’t think less fermentation gives bigger alveoli unless the dough is underproofed. More fermentation will give bigger holes if one allows that in dough handling, with less handling late in bulk and very gently shaping without patting down one will get bigger holes with more fermentation relative to a less fermented dough both being adequately fermented and not underproofed.

Anyhow, that has been my experience.

Using my aliquot jar, I bulk to 48ml after starting with 30g (~30ml) of dough + 10ml of additional water = 40ml.

So 8ml of volume expansion by 30ml of dough or a little more than 25%. Then I divide, pre-shape, rest, final shape and begin proof at that point, but the aliquot jar has progressed from 48ml to 60ml while I am doing this. I then wait for the aliquot jar to show >80ml before I go to the oven which, assuming that 48ml = 26% volume expansion, and proof started at 60ml (which is 66% volume increase from the start) and ended at 80ml which is 133% volume expansion from the start and 66% from the start of proof. I would say that I bulk fermented to 48ml and proofed to 80ml with the qualifier that the starting point was 30g + 10ml of water = 40ml.

Let’s say I start with the dough a and thin layer of water on top to make it easier to read the level and it is at 30 mL when the aliquot jar is started. I will end bulk at 36 mL, or a 20% increase in volume or 120% of original volume and go to pre-shape. After a rest shaping is done and baking will start when the aliquot jar has risen to 39 mL which is a 30% increase in volume or 130% of original volume.

Benny

I am glad I asked because that is not what I thought you meant.

That seems like a very short proof (at least compared to what I am used to).

Yes it is a very short proof, far shorter than what I’d employ for any other sourdough bread. My typical batards using strong flour I’ll bulk (all describing aliquot jar volume increase) until 60% (160% of original volume) shape immediately and then bench proof until 90% (190% of original volume) and then cold retard. Way more than for baguettes, which is why I was so hesitant to reduce bulk from 30 to 20% volume increase during the baguette CB because I never thought that the crumb could possibly be any good with so little fermentation. Again baking when the aliquot jar shows a 30% rise.

To this day, I still follow these aliquot jar rises when I bake baguettes and so far they haven’t failed me. When the kitchen is too warm and I don’t get the baguettes in the oven and the aliquot jar has gone past 30% then no ears, it is very predictable.

And it is a variable that I would not have considered to be reasonable at that value, but you now have tweaked my interest and I will have to try it. The very long proof for batards is something I do occasionally when I have a low hydration batch and I know it won't crash on me (90% aliquot jar target for oven entry) but I don't retard it first, just straight to the oven.

I have a series planned to try starting the bake at 100°C with steam only for a minute or two to get the surface starch fully gelatinized, then turn it up to 250°C and see if it gets brown before it gets done. I can get 0.5°C/sec temperature rate with my current setup so it should work. And if that works and puts some shine on the crust I will start working the retard time/temp trades to improve oven spring and max out the blisters.

My goal is to attain an open lacy crumb reliably. No deviations to making 100% whole red fife notwithstanding because there is no way I can attain this without overproofing it and then other loaf parameters are not attained. So I intend to find the combination of things that will help me achieve that crumb regularly. Fully develop the gluten up front with slap and folds, I’ve been doing hundreds up to 800 on one loaf until good windowpane is achieved. The leaving the folds for organizing the gluten to build strength. Shaping as late as possible, for me that is 60% aliquot jar rise since when tried 70% it was just too difficult for me to do. Gently patting down bubbles or popping them along the way then seen during lamination and folds. I’d like to avoid a wild crumb with huge bubbles. Then that final bench rest with the aliquot jar rising to 90% followed by time in the fridge.

It still surprises me how little my baguette bulk and proof and somehow turn out.

You mention that you will do a long proof for low hydration batards, I've been doing this with high hydration batards in the range of 78% and higher. With good upfront hand developed full gluten development so the dough can keep all the gases made so shaping at 60% and cold retard at 90% bake the next day. The goal is to have lacy crumb every time. I haven't reached this in part because I'd been working on the 100% red fife and I also like to put a lot of inclusions into my bread which effect the crumb depending on their % and size.

What is your retard process? Time? Temperature? What does the dough rest on? Bagged in plastic or covered with linen or both? Does your cooler/refrigerator circulating fan generate a lot of air movement? I am trying to get a sense of the time/temperature profile at the center of the dough.

For baguettes, once bulk fermentation is done, I place the covered bowl (reusable shower cap) into my 3ºC fridge, low shelf at the back (previously confirmed temperature) and it is usually there for between 12-24 hours depending on the schedule. For batards, they are shaped and in a rattan banneton and loosely covered by a reusable shower cap and goes into the same fridge low shelf at the back 3ºC. In both cases the shelves in my fridge are glass. The reusable shower cap is plastic and loosely surrounds the banneton with large gaps. I don’t know how to quantify or qualify the airflow in my fridge, it is a side by side Bosch of around ten years of age or so. The airflow seems good.

So it is really to stop the yeast and improve dough handling qualities rather than to slow it down and develop more acidity/flavor.

I could be wrong but I thought at 3ºC although the yeast are no longer replicating and producing much in the way of gas the microbes are still metabolically active and producing flavour compounds. Is that understanding incorrect Doc? So yes I definitely want to make the dough easier to handle and for batards, easier to score and improve the ovenspring and blisters. But I thought the flavour continued to improve during a cold retard at 3ºC.

For a long time I was using Gänzle's growth models to characterize both yeast and LAB growth. Then one day I realized that he was being driven (perhaps by choice but perhaps by his PhD advisor) to pick a model that would work for the objective of his dissertation topic and didn't need to be accurate outside of some (realistic) bounds. Thus his model is a behavioral approximation over the whole operating range of the species he was studying and is not grounded in causality in any way. One byproduct is that the details at both the high and low temperature ends of the spectrum are inaccurate by construction and perhaps very much so. With that in mind I went looking for better models and found none. That was when I began questioning what the real behavior is under those extreme conditions. It turns out (which should not surprise anyone) that some of the required measurements are hard to do. For LAB, it was possible to measure TTA for levain that was grown at low temperature for a long time and I could measure the acid being produced, but it was much more difficult to measure the results of yeast activity at low temperature. When you chill dough (or levain), the solubility of CO2 goes up and any thought you had about watching the volume increase and using it as a measure of CO2 production at low temperature is confounded by the fact that almost all CO2 produced at low temperature goes into solution or just makes up for CO2 that diffuses out of the dough through the surface. Some of the previously produced CO2 goes back into solution and I don't know of an easy way to tell the difference or to measure how much goes into solution and how much escapes. I have not examined the contribution of the low temperature metabolic products as major contributors to the flavor profile of bread - I suspect it would require some pretty tricky chromatography (GC or HPLC) to quantify what is being produced at what rate as a function of temperature but I have not even looked for research results down that path. My observation is that there is no significant volume growth of yeasted dough after it has been completely chilled to below about 38°F and that I have measured increases in TTA in levain samples that were left cold for extended periods of time. I also know that I see weight loss in starter samples that are maintained at temperatures of 39°F (± some operating fluctuation). So I treat sourdough as a black box that continues to get more sour with cold fermentation but does not increase in volume due to some combination of CO2 absorption by the liquid phase of the dough or by loss to the atmosphere through diffusion.

Doc, I remember a similar post of yours pertaining to retardation and flavor. If I remember correctly it was dealing with CY. Many bakers, including myself strongly believe that overnight retardation makes a very noticeable affect in the flavor of the bread.

Flavor is subjective and a personal thing. Do you think this is all in our heads?

I am only interested in learning, and in no way trying to be rude. I have great respect for you and your opinions.

Danny

”inquiring minds want to know...”

But the underlying phenomonology (even if known by others) remains a mystery to me. There is a lot of chemistry going on in bread dough, but whether it is yeast or bacteria that are the dominant contributors is a question for the bread science community. I suspect somebody knows (though the low temperature rate constants may not be well characterized).

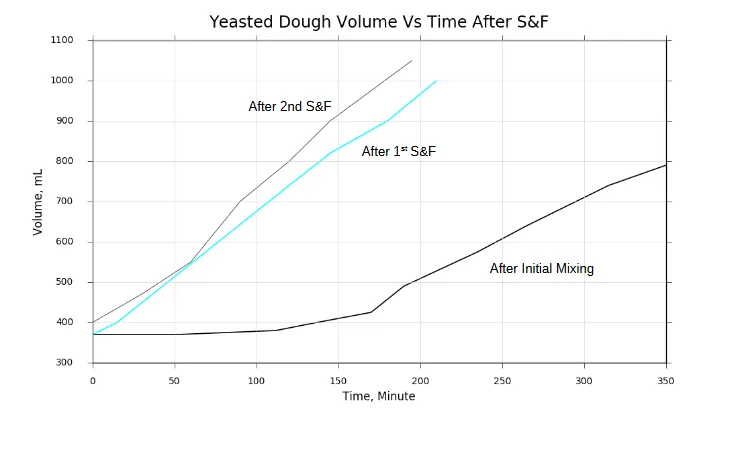

Picking up this discussion after a few years (I just came across it), Here is some data on dough volume vs time that I measured years ago using AP flour (sourdough-leavened dough performed similarly in tests, though with different time scales):

Image

I take it that the rate of increase of volume pretty much tracks the rate of gas production. Not shown here, if you let things go on too long or do too many S&Fs, the rate of rise will drop off (no surprise). If your goal is to bake when the dough is producing a lot of gas, then it's clear that you should wait after the lag time has passed and the dough has begun rising well, then do one or a few S&Fs and bake soon after.

I think this fits in with what Benny has written.

TomP

Baking with PVC sounds dangerous. I asked my husband and he said that sewer pipes aren't made to handle oven temps, but you might be able to get away with it with hot water pipes. Still, pvc fumes don't sound safe.

SugarOwl, either I mis-communicated or you misunderstood. The PVC is used in place of the Banneton. It only supports the shaped dough as a banneton would. It is not used for baking.

I'm glad it wasn't what I thought. I went back and I apparently misread it. That is a good idea if you have extra pipes laying around though, definitely cheaper than proper bannetons. I bought a couple of thick wicker baskets at the thrift store, There are always a lot them.

And really interesting on fermentation time vs alveoli. Will properly test fridge temp - we were cooking a fancy meal that night and probably opening / closing the fridge frequently over the course of an hour or so while the loaves were in there which probably boosted the temp to a point where fermentation was cracking on. Thank you so much Dan and Doc.

Sorry to revive an old thread but I am not sure if a conclusive reasoning was given/deduced for the above conundrum?

Without knowing details to your method, this is a stab in the dark.

I'm inclined to say the smaller alveoli obtained from the 43F may have been due to more break-down of the gluten structure possibly due to higher proteolytic enzyme activity as well as break-down of gluten structure from acids?

If you follow my chain of thought. . .

At 43F vs 39F, yeast activity should be somewhat higher at the warmer temperature (albeit both doughs would have retarded yeast activity due to the lower temperatures anyway). Higher yeast activity, more CO2 production on the assumption that there is still fuel left to feed on.

At the same time, we know that LAB activity also reduces with temperature. Comparatively, the metabolic pathways taken should produce more acetic acid to lactic acid (ratio) at 39F vs 43F. However, at the same time, there is increased overall LAB activity at the "warmer" temperature, so higher total acid production in 43F vs 39F. At 43F with the higher total acid production, gluten structure may be further more destroyed than at 39F?

Lastly, all else the same, proteolytic activity may be increased in 43F (due to both higher temperature and higher acidity). https://www.journalofdairyscience.org/article/S0022-0302(85)81085-7/pdf. Granted that the study is on dairy and I don't have any journal references to LAB in sourdough breads but the posts from this discussion supports the notion that lower pH activity (up to a certain extent) increases proteolytic enzyme activity https://www.thefreshloaf.com/node/67923/acidity-effect-gluten-strength . Perhaps one of the other experts here such as Debra Wink could chime in?

Keep in mind though without knowing actual pH values of the doughs above, the aforementioned is just an "educated" guess of the reason. One thing I'm not exactly sure is whether a higher acetic:lactic acid ratio at 39F would contribute to a lower pH than a total overall acid activity at 43F (even though acetic:lactic acid production here is lower). I bring up the ratio of acetic:lactic acid because from what I recall, the pH from acetic acid is generally considerably lower than lactic, but overall acidity in the combined state is at the stage an unknown to me without any measurements for comparison.

Based on my rabbit hole dive, I've been on the inclination to say that crumb structure is a high-wire balance act of elasticity & extensibility of the dough. Yes, you do need some break-down of gluten structure (for high extensibility) to obtain larger alveoli, however you also need some elasticity to hold that form. When the gluten structure is broken down too much further, you don't have enough elastic strength to hold a large bubble which then ultimately collapses which brings you back to smaller alveoli. From my experience, I notice that there seem to be distinctive differences between fine crumb structure from high elastic (from strongly working the dough for example) vs fine crumb structure from collapsed gluten structure (due to overfermentation). The latter to me always seem to appear much finer and in more random smaller clusters.

Hope this makes sense. Also, hopefully someone else along this journey might be able to fact check my arguments and correct as necessary.

Hi, thank you for this recipe, I will be trying it for sure as it would fit so well in my schedule. Could you link to the book you are referring to?

Also, I'd be keen to know if this cold bulk method would work with different flours, esp wholegrain ones-my normal loaf is 50/50 white and wholemeal, sometimes with another flour mixed in like emmer or rye.

Hi, here it is.

https://www.breadahead.com/wp-content/uploads/complete-sourdough-workshop.pdf

I have so far tried the Brown (using 5050 stoneground wholewheat and roller milled Canadian strong white flour) and white (roller milled Canadian strong white with a bit of rye) and both worked out (no mega open crumb as per my post but made great bread nonetheless). The brown one was tastier as if often the case. Really flexible - impressive!

Alex.

Excellent, I'll give the book & recipes a try- looks like they are right up my street. Just when I was on the verge of ordering a proofer...maybe it is a sign that I should save my money lol.

Your loaf looks amazing, I wish mine would rise so tall.

To be honest it's the highest one I've had an it's not typical of my bakes... I was so surprised that it was the cold bulk technique that created it! However, it also might be the extra strong flour, I normally use stoneground flour or normal roller milled and I haven't been getting as much height with those. Good luck and enjoy! Alex.

Made the stiff starter this morning, I am loving the fact that I don't have to babysit the starter OR the dough. thanks so much for sharing the recipe and the book!

Re flours: I am currently using a strong white flour (Mulino Marino 00 mixed with no 4 Shipton Mill) and the wholemeal part is currently The Prior's organic wholemeal, from bakery bits. I really enjoy experimenting with different flours but there is a lot to learn in terms of what I can achieve with each.

I know the stiff starter is a great thing... love Mulino Marinos products. Are you based in Europe? Would be great to see how you have adapted US recipes for European flours as I have had to quite a bit of experimenting to get it right! I am based in UK and like to use local and stoneground flours which tend to be lower in protein and can't take as much water.

I'm in London- in answer to your question about adapting, I just wing it :-D

I am still learning about flours but would love to find a place with all comparisons already made- so for example what's the equivalent of 'all purpose' flour? Is there such a flour in the UK?

I have so far tried the bread flour from Stoate's organic (bakery bits) and struggled to get my loaf to rise (as with Gilchester's emmer flour which I still use in small quantities just for the flavour). Realised that I needed to add less water as my dough was turning out very wet and slack.

I have just ordered another Mulino Marino flour called Pandisempre, which has rave reviews on bakery bits, so I look forward to trying it out.

I am London based too and also buy from Bakery Bits. I bought a huge sack of Stoate's white and love the flavour but really struggled to adapt it - see my post https://www.thefreshloaf.com/node/66339/overproofing-crust-texture-troubleshoot-me-friends

For all purpose I just use Marriage's Organic Plan flour. have you tried making a 100% all purpose loaf yet? I know Maurizo has a few formulas.

I have used MM's pandisempre to make a delicious pizza base!

I've just read the reply to your post about the stoneground flour, so interesting. I figured when using Stoate's myself that it was more like a wholemeal flour rather than a traditional strong white. The flavour was nice but the rise very disappointing.

My Pandisempre flour has arrived today, I'm going to bake with it next- will probably mix it with Shipton Mill's no 4. I've read some reviews that suggest mixing it with other flours works very well, but also using it on its own.

Never tried Marriage's plain flour. I have been looking at Maurizio's recipes but they scare me lol. I don't think I am that advanced yet in my baking, plus (as you experienced) I fear that adapting to my flours won't work, as he uses very specific ones and I have no clue how and where to look for local equivalents.

How exciting re your delivery - let us know how the combo turns out and what you make.

I have done a few of Maurizio's leaves - I love the very detailed description of what happens, when and the images are handy too. But before I realised just how different the flours I'm using are I had a few loaves that could have risen better or were overproofed because the stoneground flour fermented quicker than the one I was supposed to be using and I was using way too much water. All delicious mind you!

When I feel more confident, and will post a picture. I think I have been over fermenting too as I always use half wholemeal flour in my loaf. However, when I look at photos of what the dough should look like at the end of the bulk fermentation, mine never looks like that. It is really frustrating...

I have been reading on how important the dough temperature is (and I finally bit the bullet and bought a proofer!) but not really giving the difference in flours much thought-until now. Keen to see if the proofer will improve my processes.

Water, yes I use less than American recipes recommend and it has improved my results-certainly made the shaping much easier.

Agree, calling time on bulk is the hardest bit of the process for me still. When the pandemic is properly over I will invest in a real life workshop to see for myself what pros mean by all these terms - if anyone knows of a good one do let me know!

I also wish someone like Stoate's would produce some guidelines or, even better, an ebook or similar with stoneground specific guidance and formulas... again if you know of anything like this that exists please send it my way! I love the flavour of stoneground but it's a tricky one to manage. Certainly compared to this Marriages extra strong which makes shaping and rising a breeze (but doesn't pack as much of a flavour punch in my opinion).

There is a gap in the you tube market for a UK based baker demonstrating things, I have been watching videos by this guy Tom, his channel is called the Sourdough Journey. You might know him already!

Very good videos but he is American so again, same issue with different flours! The Sourdough Journey - YouTube

Yes I would greatly appreciate it if somewhere like the millers own site or even bakery bits, there was a space for recipes with that specific flour.

Bake With Jack is a great channel, and Jack is based in the UK.

I don't know that one...I'll check him out! thanks.

My experimental loaf with the above Bread Ahead method didn't work!! Perhaps my fridge is way too cold for this. Dough had zero rise and no bubbles at all after 24 hours. I followed the recipe by the letter, shaped it anyway as per instructions but instead of putting it back in the fridge, I decided to do the final proof in the proofer, (3 hours at 22 degrees- in hindsight I should have left it there longer I think). It rose a bit in the oven, but nothing like my usual loaves, and it looks like a small brick :-(

Oh well

Oh no! That is so disappointing... As you say it's very possible your fridge is just too cold. Great news for your food but bad news for bread rise..! I am measuring the temp tonight using the glass of water method suggested previously in the thread.

I am going to try the method this weekend but using stoneground flours and maybe some einkorn instead of rye.

Thanks for the sympathy! I'm still to bake the kind of tall loaf I see on the internet ahah. It doesn't help that I want to be healthy and always include wholegrains. I have never made one with 100% strong white flour.

I'm sure that this one will taste very nice despite the density of it.

Got to try the glass of water method myself to see what temp my fridge is at.

Good luck with the next loaf.

Hi all, for convenience I have been continuing to play with the 100% cold bulk process. The other day I made a 50:50 roller milled white Canadian strong bread flour / white spelt loaf and the flavour was delicious (66% hydration). Good rise and nice crust too. Note - I like a loaf with a bit of sour in there.

This week I am trying 50:50 with same roller milled white and wholegrain stoneground spelt. Will keep you posted.