Three French breads with three French flours

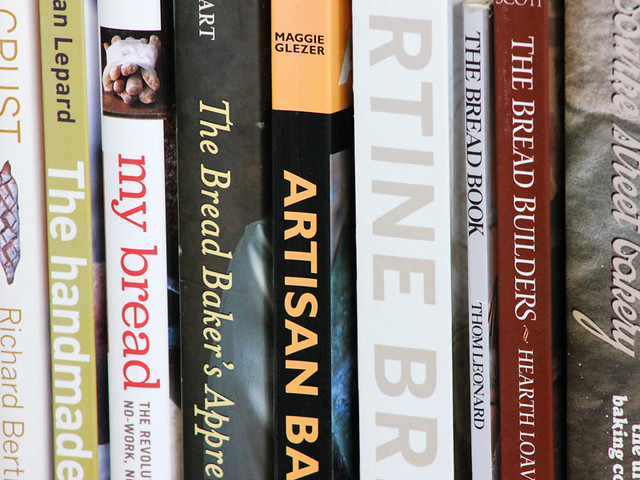

I bought a new book. Yes! another bread book. I wasn't planning to ... and thinking back I'm not completely sure where the inspiration came from, but sometimes inspiration just happens. (or in Nat's version of events ... self indulgence just happens...)

[/url]

[/url] [/url]

[/url] [/url]

[/url]