For some time I've been trying to bake breads with a bit higher hydration and a more open crumb. Each attempt I did that was over 68% hydration (20% whole wheat) failed miserably (flat breads). Then finally I realised my flour might not be up to it. I was using a bread flour that had about 11,5% of protein. So then I bought another type of flour that had 13,5% of protein. I made a nice 80% hydrated yeasted ciabatta in advance so I know it can handle this amount of water.

After this, I baked two batches of three breads, a week apart from eachother. Below you can find the recipe (same for both batches) and the schedules I followed. I'm unsure if I'm under or overproofing. I'm guessing though I'm underproofing but would like to hear all of your thoughts.

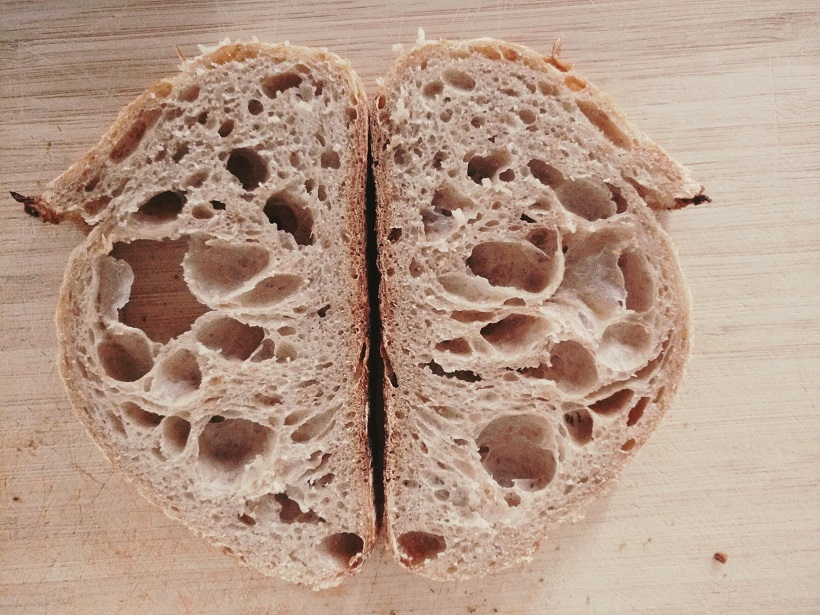

In the second batch, I bulk proofed longer than in the first batch just to see what would happen. When pre-shaping the second batch I noticed where the dough was cut, it looked glossy and was very sticky. I thought I had over fermented. The final result isn't too bad though and it's certainly edible but the crumb wasn't what I'm aiming for. I'd really appreciate insights on how to improve this.

One of my theories is, that my 100% hydration, 100% whole wheat starter is fine (doubles in less than 6hrs and doesn't smell acidic) and my schedule/handling is quite ok (though timing the proof can be better) but that the room temperature is too low (around 69°F or less) to give an optimal rise to this relatively white dough (80% breadflour, 20% wholegrain). The 100% whole wheat starter and 100% wholewheat levain (pre-ferment) have a lot of nutrients for the yeast to thrive, even at a lower ambient temperature or so it seems. Then when I add the levain to my autolyse to make the main dough, the yeast cannot grow at the same rate anymore because the white flour contains less nutrients (and also because of the lower hydration in the final dough). So what I'm wondering is, could it be possible because of the lower ambient temperature the lactic acid bacteria are catching up with the yeast and taking over before the dough is fully proofed and puffed up? This would explain the glossy look of the dough after cutting it, the lactic acid impeding the growth of yeast and preventing a better crumb.

In despair I was looking into a bread proofer online, wondering if it was the only solution to this situation. A higher ambient temperature would boost the yeast's CO2 production, giving the lactic acid bacteria less time to acidify the dough and deteriorate the gluten. Does that sound right? Is it even possible to get such an open crumb at these lower range proofing temperatures?

I've tried placing my dough in the oven at 30°C during bulk before, but this didn't work. After measuring I noticed the actual temperature in my oven was 40°C (which is too high of course) and I cannot configure a lower temperature on that oven. Also I cannot find a warmer place in my house for the dough. The fridge and freezer are built in to a cabinet so I cannot place it on top for some added heat. Any advice is much appreciated! So here's the recipe and schedules, together with some pictures.

Recipe:

20% whole wheat 75% hydration (500g/loaf)

Levain: 214g (25% of weight of total flour)

Water: 536g

Wheat flour (13,5% of protein): 686g

Whole wheat: 64g

Salt: 17g (2% of weight of total flour)

Schedule batch 1:

I took my 100% whole wheat, 100% hydration starter out of the fridge and fed it equal parts starter, water and whole wheat flour (1:1:1) at the following times:

Friday 9AM

Friday 9PM

Saturday 9AM

Saturday 3PM

Saturday 9PM (I intended to feed 1:2:2 so it would peak later, but forgot and did a 1:1:1 feeding instead)

Then on Sunday:

8AM: made the levain (pre-ferment) from 71g of my starter (which didn't smell acidic and doubled in volume), 71g of water and 71g of whole wheat (1:1:1)

11AM: prepared the autolyse from the remaining water, flour, whole wheat and salt

1:45PM: the levain has more than doubled in size so I incorporated it in the autolyse. Bulk proof starts here. The ambient temperature is around 21,9°C (71F) which is quite warm for my kitchen.

2:45PM: did some strong stretch&folds in the mixing bowl

3:30PM: lamination (stretching the dough thinly over the kitchen counter). I left the dough lying there for about 5 minutes before picking it up to create additional dough strength. I saw this technique in this video on high hydration Roman pizza dough. In the second batch I try to determine how much water evaporates by doing this. Then transferred the dough to a rectangular pyrex dish which I cover with a plastic box turned upside down (to prevent drying out the dough)

4:20PM: coil folds

5PM: coil folds (large bubbles appeared on top of the dough, dough was starting to feel airy)

5:40PM: coil folds

6:20PM: coil folds

7PM: pre-shape. Divided the dough in three parts without weighing them (to minimize handling the dough to prevent escape of gasses) and carefully made circular shapes by gently folding the outsides of the dough to the inside

7:30PM: final shape. I flip the dough upside down, fold left and right side to the middle and roll-up the dough from top to bottom. Then transferred to bannetons. One of the three doughs went immediately to the fridge for a cold retard. The other two I keep in my oven (turned off) for a final proof.

8:35PM: second dough goes to fridge

9:15PM: third dough goes to fridge

On Monday at 7:30PM I start baking these. I don't have a Dutch oven but use a 'tajine' which has a cast iron bottom and a ceramic lid. Unfortunately it has a small hole on the top where steam can escape but surprisingly it still works well. The highest my oven will go is 225°C (437F) and that's where I bake at (fan always off) for 20 minutes in the tajine with the lid on. Then I remove the lid and continue to bake at 200°C (392F) for another 15 minutes with only the bottom heating element from the oven turned on. The inner dimensions of my oven are quite small and when I do use the top heating element without the tajine lid, the crust get thick really quick because of the heating element being close.

Although the loaves had different proofing times, the crumb of each was quite similar. I didn't take pictures of each.

Here's the pictures:

Schedule batch 2:

I took my 100% whole wheat, 100% hydration starter out of the fridge and fed it starter, water and whole wheat flour as follows:

Friday 1PM (1:1:1)

Friday 9PM (1:1:1)

Saturday 9AM (1:1:1)

Saturday 3PM (1:1:1)

Saturday 9PM (1:2:2)

Then on Sunday: 7:45AM: made the levain (pre-ferment) from 71g of my starter (which didn't smell acidic and doubled in volume), 71g of water and 71g of whole wheat. Ambient temperature was 20,5°C (68.9F)

9AM: prepared the autolyse from the remaining water, flour, whole wheat and salt

1:30PM: the levain has more than doubled in size so I incorporated it in the autolyse. Bulk proof starts here.

2:20PM: did some strong stretch&folds in the mixing bowl

3:05PM: did some strong stretch&folds in the mixing bowl

3:50PM: lamination (stretching the dough thinly over the kitchen counter). I left the dough lying there for about 5 minutes before picking it up to create additional dough strength. The weight difference before and after lamination was 14 grams. This included dough that stuck to the counter, my hands and the evaporation. 14gr makes 0.9% from the total dough weight. Then transferred the dough to a rectangular pyrex dish which I cover with a plastic box turned upside down (to prevent drying out the dough)

4:45PM: coil folds. Dough temp 21,3°C (70F) (large bubbles appeared on top of the dough, dough was starting to feel airy)

5:30PM: coil folds. Dough temp 21,5°C (70.7F)

6:15PM: coil folds. Dough temp 21,5°C (70.7F)

7:10PM: coil folds. Dough temp 21,7°C (71F)

7:50PM: coil folds. Dough temp 21,9°C (71.4F) (large bubbles on top of dough dissappeared)

8:30PM: pre-shape. Divided the dough in three parts without weighing them (to minimize handling the dough to prevent escape of gasses) and carefully made circular shapes by gently folding the outsides of the dough to the inside

9:10PM: final shape. I flip the dough upside down, fold left and right side to the middle and roll-up the dough from top to bottom. Then transferred to bannetons. One of the three doughs went immediately to the fridge for a cold retard. The other two I keep in my oven (turned off) for a final proof.

9:50PM: second dough goes to fridge

10:20PM: third dough goes to fridge

On Monday at 6:30PM I start baking these the same way as batch 1. Here's the pictures:

Sorry, I can't help with your breadmaking problem because, as you say, your thread looks bad and is difficult to read!

Two thoughts:

1) You have no paragraphs. Text needs to be split up into paragraphs to make it presentable. A little intuition should help you determine paragraph breaks. Also make sure you have a line space above and below each picture and between picture and text.

2) Your post is suffering from information overload - there is just too much information there for the reader to take in - can you precis it down, trimming out any unnecessary information?

Perhaps try editing your post and it will make it easier for us to help you.

Lance

Hi Lance,

something went wrong with the text after I hit the 'save' button, so today I removed and added the text again and now it's looking better. Thanks! :-)

Well done - I can read it now!

Mariana has given you good advice - the "modern way", which is actually the old way, of developing gluten up front either by hand or in a mixer and then doing a few folds at half hour intervals to give structure will give good results.

I agree with your comments regarding a proofing box; many bakers don't feel the need for one, but I can't imagine baking without one - it's so much better to have a constant temperature and know that certain things are like to happen at time x or y. Of course there will always be some variation, but a lot less than if you are not using one.

I guess it also depends on where in the world you live and the ambient temperature in your home. But in Northern Europe I would say it's very useful!

You can easily make a proofing box with a closed container, germinating mat, thermostat and small fan - lots of designs on TFL or Google. It can be as simple or sophisticated as you want it to be.

Lance

Hi,

my advice would be to go back to that excellent video that you linked (Pizza al taglio ad alta idratazione) and watch how this person kneads their dough before they add the second portion of water, and AFTER. Their gluten is fully developed even before they start folding it, layering it with oil, water, etc.

You will get excellent results if you copy what they are doing with your high hydration bread dough. If you don't have a mixer, then develop gluten by kneading by hand, like so, for 20-30 min non-stop

And only then introduce the remaining water to make dough softer and ready for folds.

Flour protein and provenance is pretty much irrelevant. You can make great holey crumb with 100% and even 120% hydration dough with type 55 bread flour that has only 10% protein. No problem. The trick is to knead it well, to develop gluten sheets before you add all that extra water in small increments, drop by drop if necessary. Once gluten is developed, it becomes impermeable, strong, and will retain all that water inside dough and give you the crumb of your dreams.

Of course, it is possible to develop gluten with the aid of time - the no-knead dough way. The same person shows how they do it by giving their high hydration pizza dough 40 hrs in the fridge - a very slow alcoholic fermentation develops gluten in yeasted and sourdough doughs as well.

Lactic acid doesn't impede growth of yeast. Not in the slightest. Yeasts are ok with any acid and any amount of it. Mold (which is yeast, fungi) grow even on lemon slices and those have a very low pH, lots of acid. Sourdough starter for panettone is kept at pH equal to 3.2, which is incredibly acidic, and sourdough yeast thrives in that super acidic very stiff sourdough.

White flour doesn't make yeast grow slower either. It is perfect for starters and all French and Italian style starters, both stiff and liquid, are fast rising and are made exclusively with very white bread flour.

Bran in whole grain flours acts as prebiotic for sourdough bacteria, they multiply like crazy in whole grain environment. And where bacteria grow, there yeast will grow as well, since they are in symbiotic relationship with each other.

Thanks for your input Mariana! So you think the issue here is with gluten development?

The lamination I do is in fact one big 'window-pane test' and to me it seems the gluten are even at that early stage already pretty well developed. After lamination there's still plenty of time and coil folds to keep developing the gluten.

Anyway, I'll definately keep it in consideration to do additional kneading/stretch&folding next time I'm making the dough :-)