I've been using the information and everyone's helpful suggestions on TFL to help me fix up my N-50. The last step I needed to do was to replace the power cord. It was stiff and brittle with the outer casing/covering starting to break open. Before any wires would be exposed, I wanted to get this taken care of and make sure it was safe. The cord enters my older N-50 at the base of the mixer and not at the motor end-cap as found on the newer models. Finding the original cord set as being unavailable from Hobart, I took a gamble and went online and found another cord assembly that is available from Hobart. It comes with a strain relief as part of the cord and with a "C" clip that slides over the strain relief once inserted into the mixer body. The only modification required was to cut the crimped terminals that were on the black and white wires of the cord set, then strip off the insulation and wire nut the connections together as they were previously found in the mixer. The ring terminal for the ground wire attached perfectly where the old cord ground was attached. The Hobart part number for the cord I used was 00-123856-00001 . I look forward to working perfectly for years to come.

Any pics on the finished product?

I'll get them when i have a chance. My wife is having it run overtime making Christmas breads and cookies. Today, while not breads or cookies, it was a double batch of pierogi dough.

Here's my attempt at pictures. This first couple show the typical degradation of the grease that was inside of the transmission.

Finished and back together with 20oz of LPS Thermaplex FoodLube as directed by Hobart service. you can see the new cord set I put on it with the strain relief.

While I'm at it, here's the N-50's big brother we have, an A200 . It has the 12 QT bowl and beater on it right now, but if needed we can easily put on the 20 Qt bowl and attachments.

A lot of old grease in the gearcase

Yes Camarie, it was a dirty job. I even got my wife involved as she was able to reach into nooks and crannies I could not get my sausage fingers to get in to. We got 2 containers like you see below out of it.

What kind of grease did you replace it with?

The grease we used was directly from Hobart. It was listed as Part number - 00-937751-00001, Description -LUBRICANT/CONTAINER ASSY ( 8 oz. ) . Hobart Service said 20 oz was needed so 2 1/2 - 8 oz cans of this lube was required. It looks like the grease Hobart supplies is LPS Thermoplex Foodlube. They want an arm and a leg for it, but I think you can find the same grease MUCH cheaper online.

Thanks Could be used for the n50 as well, right?

Yes, Camarie, this is what was recommended by Hobart for the N-50 and what I used in my N-50. My A200 was a different story. Hobart recommended 32oz of # 00-103881-00047 LUBRICANT,/CONTAINER ASSY grease in that.

The N50 has been working very well since the last time I posted here about it, UNTIL this morning. We were making some GF cherry squares and all of a sudden there was a burning smell. It was very slight at first, sort of like the smell you get when you use an toaster over for the first time. It then rapidly got worse to the point were the blade stopped turning. As I went to get my tools, my wife experimented and found she could still run it on speed 1. Not what I would have done!

What I thought what was wrong with the N50 was that the motor had burned up as it smelled just like it. I unplugged the unit and took the rounded back cover off, to inspect the motor windings. They looked fine and shiny not darkened or charred. I then thought the next culprit could be the on-off switch. I pulled off the switch plate and switch and I found the "smoking gun"!

Looking at the picture below, you can see the round barrel contact that is burned away on one side. When the switch is on, the round barrel is supposed to roll to the left and make contact with the brass part. It was burned away so much, it did not roll well AND it was eaten away and not making contact anymore.

For reference, this is what the other side of the switch looks like. Notice no burned away edges on the round barrel.

So I went to the Hobart site only to find the switches were no longer available there. I took a magnifying glass and looked at the burned switch. On the side I could make out A-H+H and some other info including USA. I googled "A-H+H". Low and behold I got a hit for at a company located at Tedss.com. Looking through the 12 pages of switches there I found switch model # 8000L . While the wire attaching points look different than the original, I think it will work fine and allow the interlock with the power switch to continue working. A picture is below. Best of all the price for the switch was really decent. At only $ 5.00 I have nothing to loose and only an N50 to get back. When I get the switch in, I will add to this thread. I thought this info could be useful to others that may be in the same predicament.

I am in this predicament - except my switch simply won’t flip back to the off position. Thanks!

Hi,

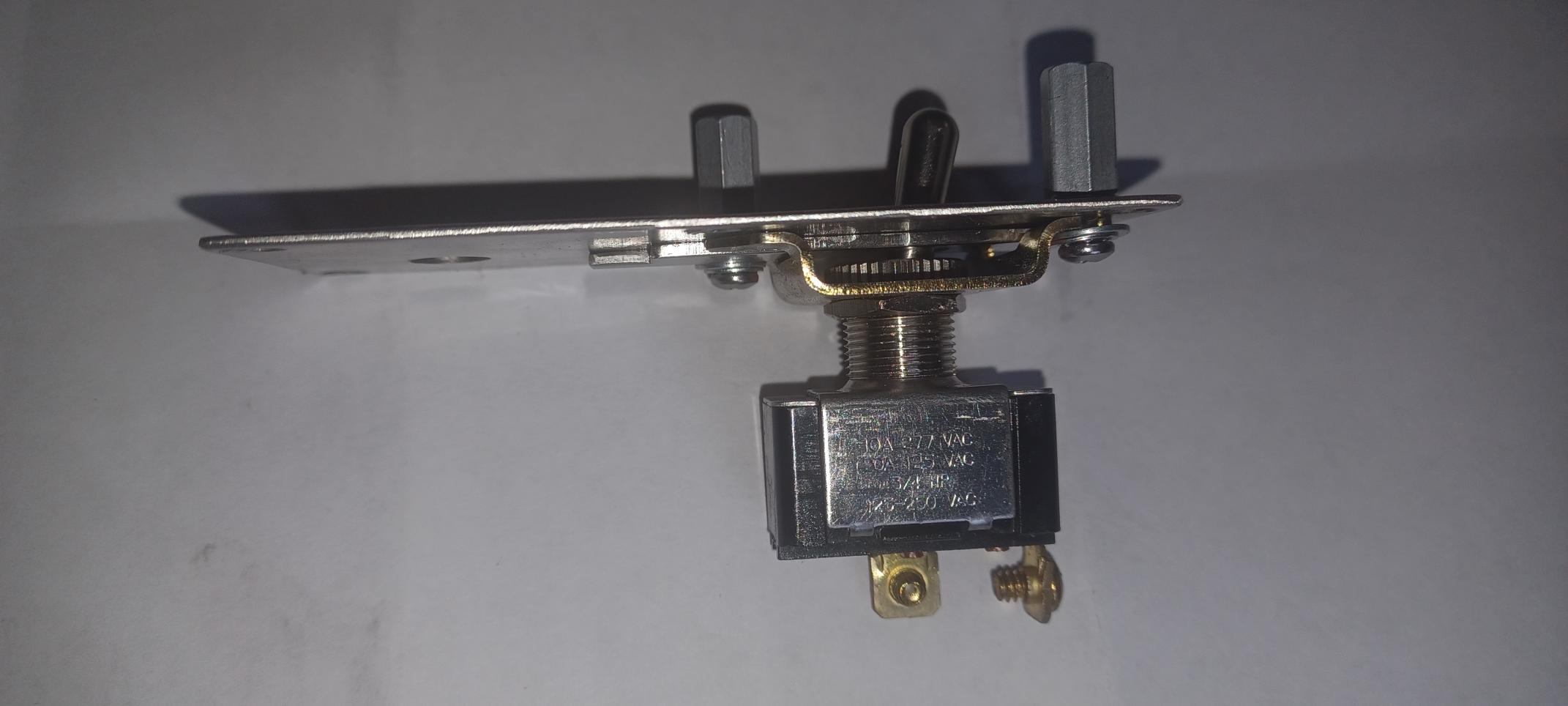

Did you end up fixing your switch plate assembly? If not, I finally got around to putting an updated kit together with a new toggle switch, slider, switch plate, and torx mounting screws, but you would have to use your own shifter handle Let me know if this will help?

Hello everyone,

Though the N50 rebuilds that I have done in the past I have encountered the problem of the disintegrating bakelite switch. I always wanted to put together a kit but never got around to it. I have had the switch plate made for a while and have not done anything with it until now. My costs were not cheap between machining, etching, switch costs, bracket and hardware which I am still getting together. To be honest there is an online seller with a lower price than what I intend to sell the kits I have but I need to cover my costs. In the end I will have a higher price. The picture is what the assembly looks like but will not include the lever. The two hexagonal studs act as guides to prevent accidentally switching the mixer on just the modern N50s. My hardware will include torx screws for mounting instead of the slotted factory screws.