Sourdough Guide

- Log in or register to post comments

- 4 comments

- View post

- Doc.Dough's Blog

Since this is a process of discovery more than an exposition of well understood science, the update number in the title will change when enough significant changes have accumulated that you might want to re-read from the top. At some point it will stabilize but in the beginning it is somewhat volatile as I discover/uncover truth and apply a dope slap for what proves to be erroneous.

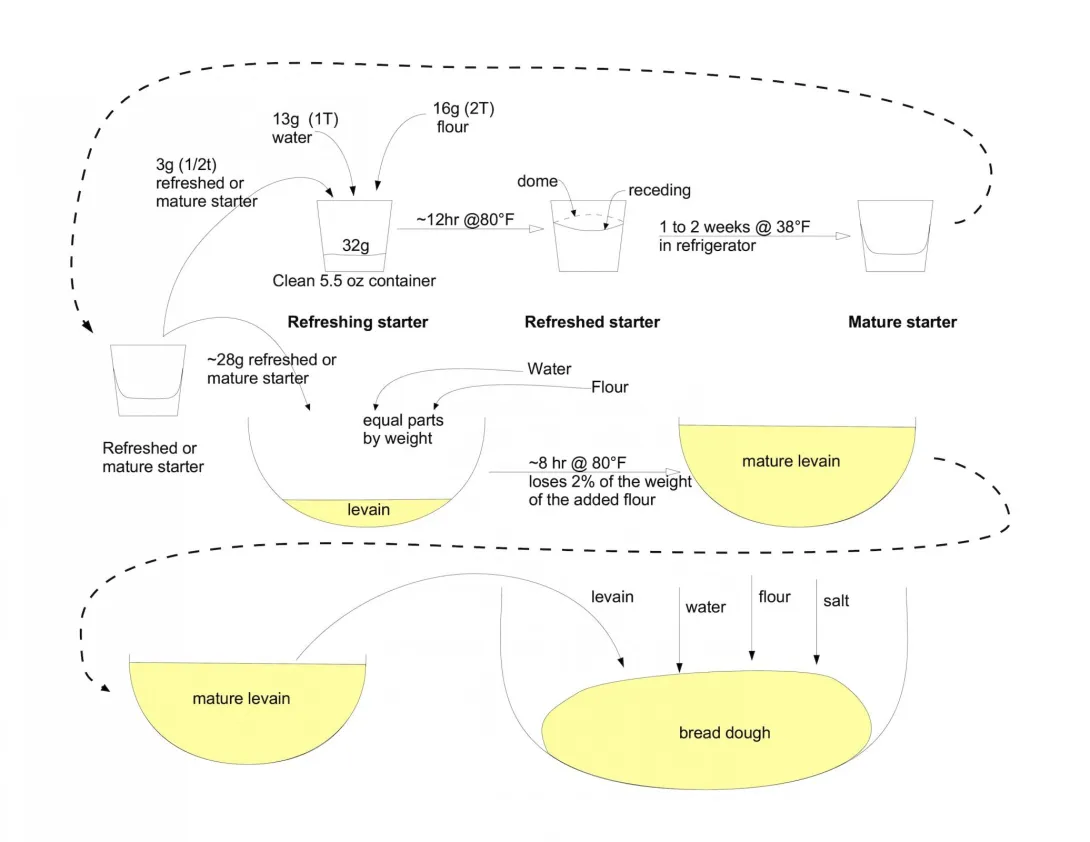

Since the facility for uploading fully formatted Word and PDF documents has not been implemented, the details of this post can be found here and I have loaded (above and below) a pictographic shorthand version which lacks any explanation of the rationale. The artwork covers the whole bread-making process of which the illustration above covers starter maintenance, elaboration into a levain, and then using the levain to initiate a batch of bread dough. The linked paper covers only the starter maintenance and

In reviewing a few month's worth of baguettes, I found that a batch from 9/21/20 that had a nice open crumb and an unusually long and high energy mix. It was made with high gluten flour, 68% hydration, long mix time (5 min @speed 0 [low speed], 18 min @4 [high speed]), and 78.6°F dough temperature at end of mix.

9/21/20 (high gluten flour, 68% hydration)

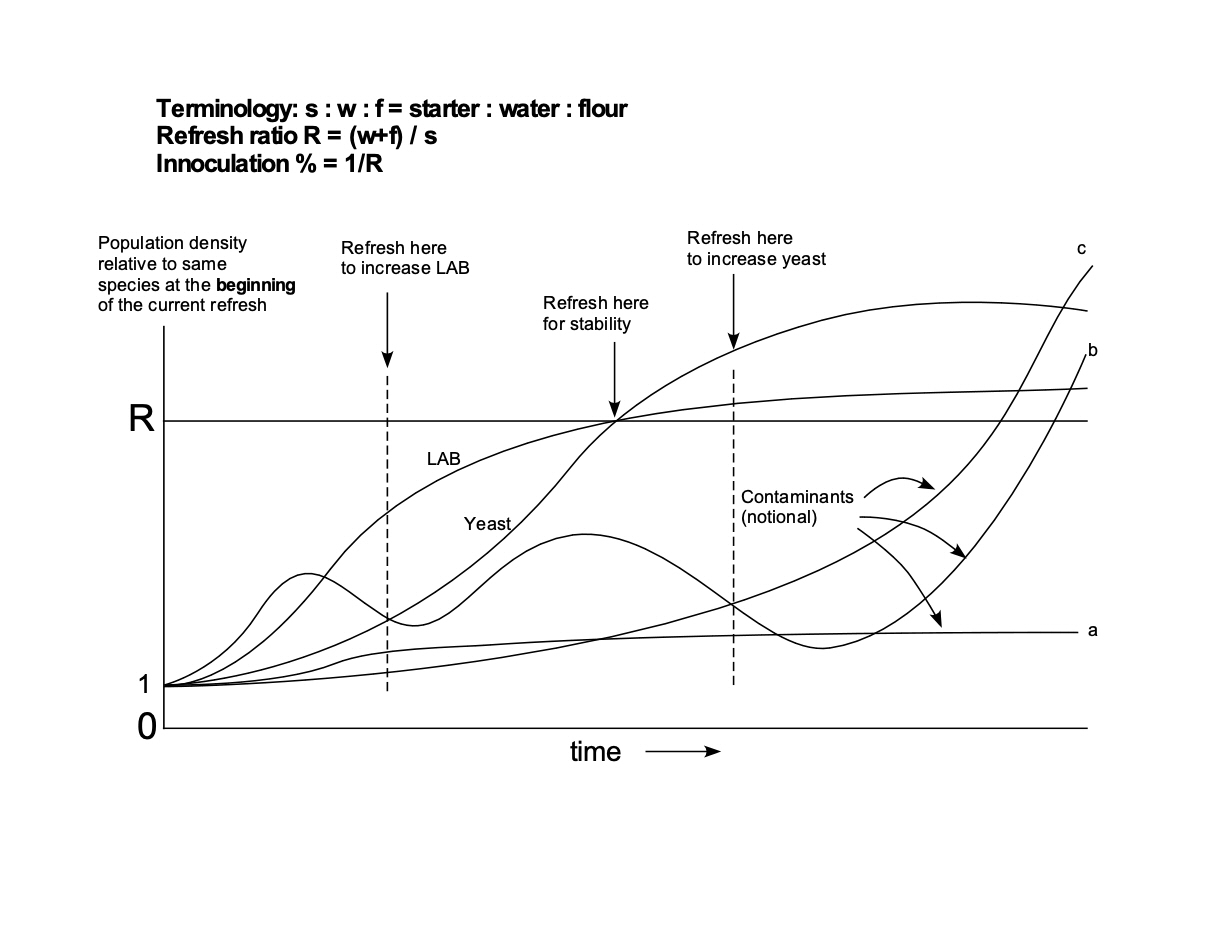

Since the facility to accept text from Word documents is not yet implemented here, the text of this post can be found at this link. The figure below is notional but while it does not reflect lab measurements, it should be thought of as an aid to thinking about the underlying issues.

A friend asked for some help with a recipe for a Portuguese corn bread known as broa, and the formula she had been given was not working for her and was producing hockey pucks. So, having not made any corn bread for a long time I decided to try and figure out what it should be.

It turned out to be one of those on-line formulas that was probably never tested as written and was destined to produce pretty good hockey pucks if you followed it. But it did give some history and I found some photos that were helpful but nothing that seemed to be really authoritative.

Below is a proofed demi-baguette that was marked with lines spaced 1.25" apart. It is about to be baked without any steam as a baseline for testing the hypothesis that steam facilitates the stretching of dough. Since this loaf is not scored, we should expect it to blow out along the side. But still, if the surface stretches in response to internal pressure generated by the expanding CO2, then we will be able to observe and measure how much stretch there is.

This post has no pictures and is not going to interest a lot of readers since I did it to help my own understanding of what is going on in the oven. Writing it down forced me to explain more when I didn't understand why and fix apparent inconsistencies. If it is too much technobabble, just jump out and find something interesting.