Dan's recent questions, and all of the recent discussions about yeast water have made me think of ways of making it more reliable.

With a double build preferment, as was done in the Swiss Farmhouse community bake, yeast water breads can be reliable. We end up waiting to see if the first build of preferments starts to increase in size and show all the signs of active yeast fermentation and then use that to start another preferment which is used for the final bread. It works reliably once we know the first preferment works and because of the high amount of preferment in the final dough the bread bulks and proofs rapidly. The trouble is that it involves advanced planning!

A single build preferment, while not as reliable does work too (however, occasionally it fails to grow, and it is hard to gauge visually if the fizzy yeast water in the fridge has enough active yeast).

But what if we could drop the preferments altogether and just work with the liquid yeast water directly in the final dough? Other bakers, like Caroline seem to be able to get this to work. Maybe they just use a large amount of yeast water; or there is confidence that it is fresh and was fed recently. When I've tried it, it has been haphazard with the occasional 20 hour plus fermentation time, so not reliable for me yet.

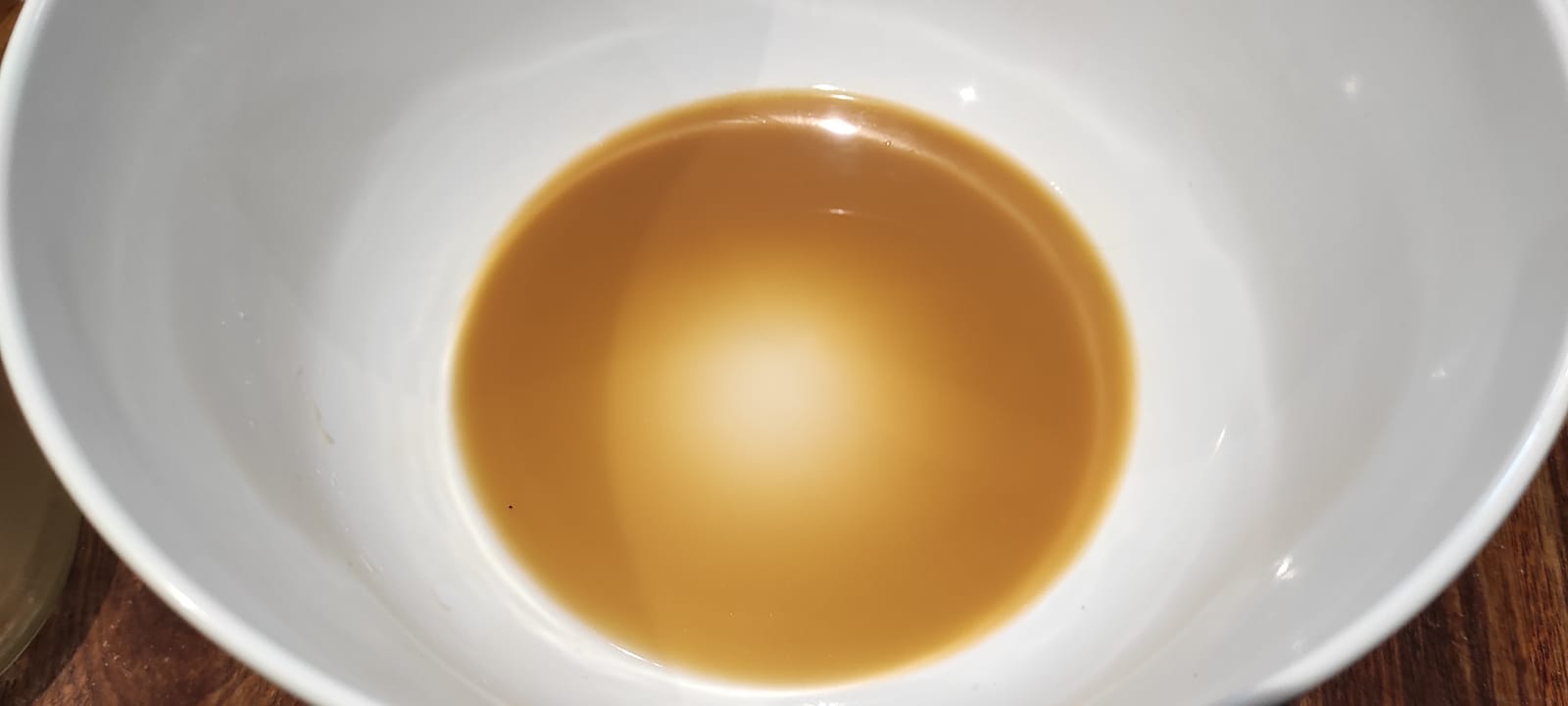

The recent experiments with the sediment at the bottom of the yeast water jars for me indicated that it might be possible to use that as a form of 'concentrated' yeast water. It worked well at a high bakers percentage in that basic test - 20g of sediment/slurry had strong raising power.

How would it work as the sole leavening source for a bread? What I like about malt yeast water is that it propagates rapidly and there is no requirement to strain fruit pieces.

For this bread then, I cultured 56g of existing malt yeast water with 71g of malt extract syrup and 710g of water (so a ratio of 1:10 malt extract to water). After 24 hours, even with the jar kept exclusively at fridge temperatures, which I prefer to do, there already seemed to be a large build up of sediment. Wasn't ready to bake then so used it a day later when it was 45 hours from the initial feeding. After siphoning off the top I could get 41g of the concentrated sediment that was settled at the bottom of the jar. It was surprising that it was only 41g - thought it looked like more and maybe I should have left it in the fridge for more that 45 hours to get more sediment.

This 41g was used to make a bread with 400g of flour (so the concentrate was at a baker's percentage of 10.25%). It performed a bit like a slow sourdough, and took 6 hours at 26°C(79°F) before the dough was at about 55% volume increase when it could be shaped and cold retarded overnight. A lot slower than the initial basic test, but the amount used was much lower.

Here's the bread after baking the next day:

(What makes the bottom lift like this on the baking steel? Baked at 230C for the initial part of the bake when it lifted like this; it almost looks like it is hovering on the breadboard!)

The lazy part of me is questioning if this method is worth doing when it is very easy to go and buy a sachet of instant yeast which would have a similar effect. I guess the bread itself, because this is yeast water might be more acidic than with commercial yeast, but don't yet have a pH meter to confirm that! It was certainly nice enough to eat, see the pic for yourself.

I think this approach might be more successful with faster fermentation, and for that would probably need a larger amount of the concentrate and to try it at a baker's percentage of say 20% or higher (but would also have to make sure that the non-diastatic malt added in wouldn't get too high!).

-Jon

- JonJ's Blog

- Log in or register to post comments

Interesting alternative bread experiment. I would guess from the apparent lack of a score that the steam couldn't escape and inflated the loaf like a balloon which made it rise off the stone.

Don

Good thinking, unfortunately I gave it a shallow X score as per this pic, unless it wasn't deep enough?

I have had a few that were fully proofed or was it under steamed that the slash sealed up and the blew up without bursting. Maybe the abundance of sesame seeds caused it to happen.

Could Glutathione have produced such an extensible dough that the scores didn’t open and set and the dough ballooned because it was so stretchable. Grasping for straws here.

A crumb shot showing the crust (all sides) may help.

I agree with Don, the loaf does look like it wasn’t scored and yet it was. Because the scored didn’t open up, rather than relaxing as the baking went on, the loaf acted as a balloon. So the question is why didn’t the scores open up? The usual suspects come to mind, did the dough just over ferment a bit so gas expansion in the dough wasn’t able to held in by the gluten and instead was lost to the oven.

Dan mentions the glutathione, this is another suspect. I assume, rightly or wrongly that it makes the dough more extensible by damaging the gluten somewhat. If that is the case then that could be why the gluten wasn’t able to retain the expanding gases and as such the dough couldn’t open up as much as it should have at the scores.

Regardless the bread looks great Jon and it was a great experiment.

Jon, Debra made a great point concerning the sludge on the bottom of the YW jar. She mentioned they were dead cells. Dead yeast cells is how glutathione is made. Glutathione will make a dough very extensible (stretchy). Glutathinoe is sometimes used to make baguettes easier to roll out and elongate.

Did you see this characteristic in your dough?

Hi Danny,

Sorry for the confusion. I wasn't saying the sediment is only dead cells. On the contrary many are alive. But the dead cells are more likely to be at the bottom, and the more sediment there is, the more dead cells are likely to be in there.

The weird rheological issues I sometimes see is more of a cottage cheesey look to the dough that develops during mixing and doesn't smooth out until after some fermentation time. Another thing I've experienced is a strange, almost astringent feel to the stiff preferment(s) that is/are hydrated with yeast water. I don't know how else to describe it, and I don't know what that is. The first preferment always ends up very slack and fluid-looking by the end of its fermentation period though.

My best,

dw

Debra, what should we do about the sludge on the bottom of the YW jar?

Another question -

Can the sludge (glutathione?) be used to to make a dough more extensible. Similar to Nutritional Yeast?

Speaking for myself and all TFL bakers, we appreciate the fact that you monitor and post to this forum.

Thanks to you, my starter is super active and consistent. And has remained so for years…

So, this is where you need to use understanding and common sense type judgement. As long as the liquid you're taking is cloudy and bubbly, there are plenty of active cells there to easily kick off a new jar. And you don't need but a splash of it. I typically only transfer about a teaspoon from the top over to a second jar with new fruit and fresh water. I see bubbles within 12-24 hours, and it's ready to use a few days after that (I like to wait until it changes to that beer-y smell). But honestly, all it would take is a drop. The quicker you need it ready, the more you can use.

Or I may just pick out two or three of the spent raisins and use that to inoculate the next jar. I seldom just add to the same jar unless it is relatively young and I'm in a baking cycle that needs a quick turnaround time. But that's just my preference. All the dead cells and spent raisins will start contributing off flavors to the liquid at some point, like wine gone really bad. And the bread does get some of the fermentation flavors and aromas from the prefermented liquid same as using wine or beer in place of part of the water. So taste it, because that should help inform your decision.

If the liquid at the top is clear (no cloudiness) and everything -- yeast and raisins -- has sunk to the bottom, then you should resuspend or take some from the bottom to inoculate the new jar. It's less of a sure thing if it's very old, but you'll find the quiescent cells there. Point being that cloudiness indicates the presence of active cells, and clear means they've gone quiet (and/or dead in time) and settled to the bottom. Hopefully that helps to demystify the decision-making. Like sourdough, there is no one right way to do things. Because as always, it depends ...

Sorry, I can't answer the sludge as dough improver question because I haven't tried it in that capacity. But that's another great experiment opportunity for you :)))

My best,

dw

Your description sounds like that of coagulation, the effect of acid on the proteins, analogous to what acids do to milk to produce yoghurt or cheese. But redox may also play a role regarding your descriptor of astringent. The key here is the effect of acidity.

Generally, as the pH goes down the redox potential tends to go up, if you understand redox then this is explained by the medium becoming more and more positively charged at a lower pH. If you consider one of the earliest understandings of acids, that they are proton donators it might help to make things clear.

Back to coagulation, the dough may well split, a bit like curdled custard, the proteins shrink and become less able to bind with each other. And back to redox, the effect of over oxidation will also cause inextensibility and even tearing while rising.

Reduction caused by glutathione would not cause these problems. Rather reduction would help smooth things out and relax the dough, countering the effects oxidation. And finally acidic enzyme proteolysis would also cause a smoothing out effect.

Best,

Michael

Hi Michael,

Good things to think about -- especially considering that raisin water brings along citric and malic acids with it that are stronger than acetic or lactic. Malic in particular catches my attention because according to Wikipedia "The taste of malic acid is very clear and pure in rhubarb, a plant for which it is the primary flavor." Raw rhubarb has that same sort of feel that I think of as astringent. And then there's tartaric which tends to crystallize and settle to the bottom in the sludge layer.

On the other hand, the pH of my raisin water (4-4.5) doesn't seem to be acidic enough for that to be causing problems at the final dough stage where it is more diluted and buffered. That's where the curdled look shows up if and when it does. It goes away with folding during fermentation.

reduction would help smooth things out and relax the dough

This is the effect I get in the first levain build.

Thanks for your insights,

dw

Doesn't need any intermediary step but I do it for two reasons. Firstly my introduction to YW was through Hamelman's Swiss Farmhouse Bread so it's a method I stick to often. And secondly, the yeast water is not for flavour from the fruit I'm necessarily using. That will come from the recipe I'm making. Other then that it's plenty strong enough to be used either way.

I fed my RYW yesterday at noon as all the fruit was on the bottom and the liquid was very clear.It had been kept in the fridge and was ready to be refreshed as I was baking today. I poured off almost all the clear and a few bits of the sludge that floated into the new clean container. I added new Giant Flame raisins. By 8 pm 1/2 the raisins were floating but there wasn’t any fizz . I saw 1/2 an organic Honey Crisp on the counter and cut it up and added. Went to bed and this morning it looked fabulous. Used 2c of clear liquid for a 3# batch of my Challah that I had converted to YW some time ago. I immediately added filtered water to the container and set in a warm place 3 hrs ago. No new fruit only 2c water. It’s beautiful again and put it into the fridge as I am going to use it tomorrow again.

That top image is very impressive. If I can find some organic apples, I’ll give that a try.

My concern (in south Louisiana) is that even the organic apples will be waxed for presentation. Just read this on the Internet.

” An easy way to figure out if your apples have wax is to place them in a bowl or in the sink and pour boiling hot water over them. If you see a white, waxy film start to appear over the peel then you know you have wax on your hands.” The boiling water is sure to kill the microbes but a test chunk could be sliced off and used to test.

I was pleased at the quick turnaround after just adding water this afternoon and already it’s so active! I have always had a better response with apple than raisins. I just really like both together now which someone posted .. maybe Jon? Anyway I get beautiful organic fruit at Walmart. They are increasing their organic offerings all the time and the quality difference is striking. We also have an excellent farmers market.