My wife has been baking sourdough bread in dutch ovens and we are scaling up. We bought a convection bread oven (the kind used at subway) and I added my own steam injection system. My question is about timing and temperature.

Currently she cooks the bread in preheated dutch ovens closed for about 20 min then removes the covers and continues until they are finished (like 30-40 min). The temperature is 450 the whole time.

How should we time the steam (ie. start it before putting the bread in the oven for x number of min, and continue steam for y number of min) and what is the optimum temperature?

Any help is appreciated.

and should be used for the 2nd half of the bake. Because it distributes the heat more evenly, you should turn down the temperature so that the crust does not get over done while the internal bread continues to bake. I bake 500g batards as I can do two at a time on my baking steel. First temperature is 460F (no convection) with steam for 15 minutes. Steam is removed (towels in a baking pan) and temperature is lowered to 420 WITH convection. This does a perfect job for me. If larger loaves were to be baked, the 2nd half of the bake would probably need to be somewhat longer but that can easily be tested by measuring the internal temperature of the bread (205F is what I go for).

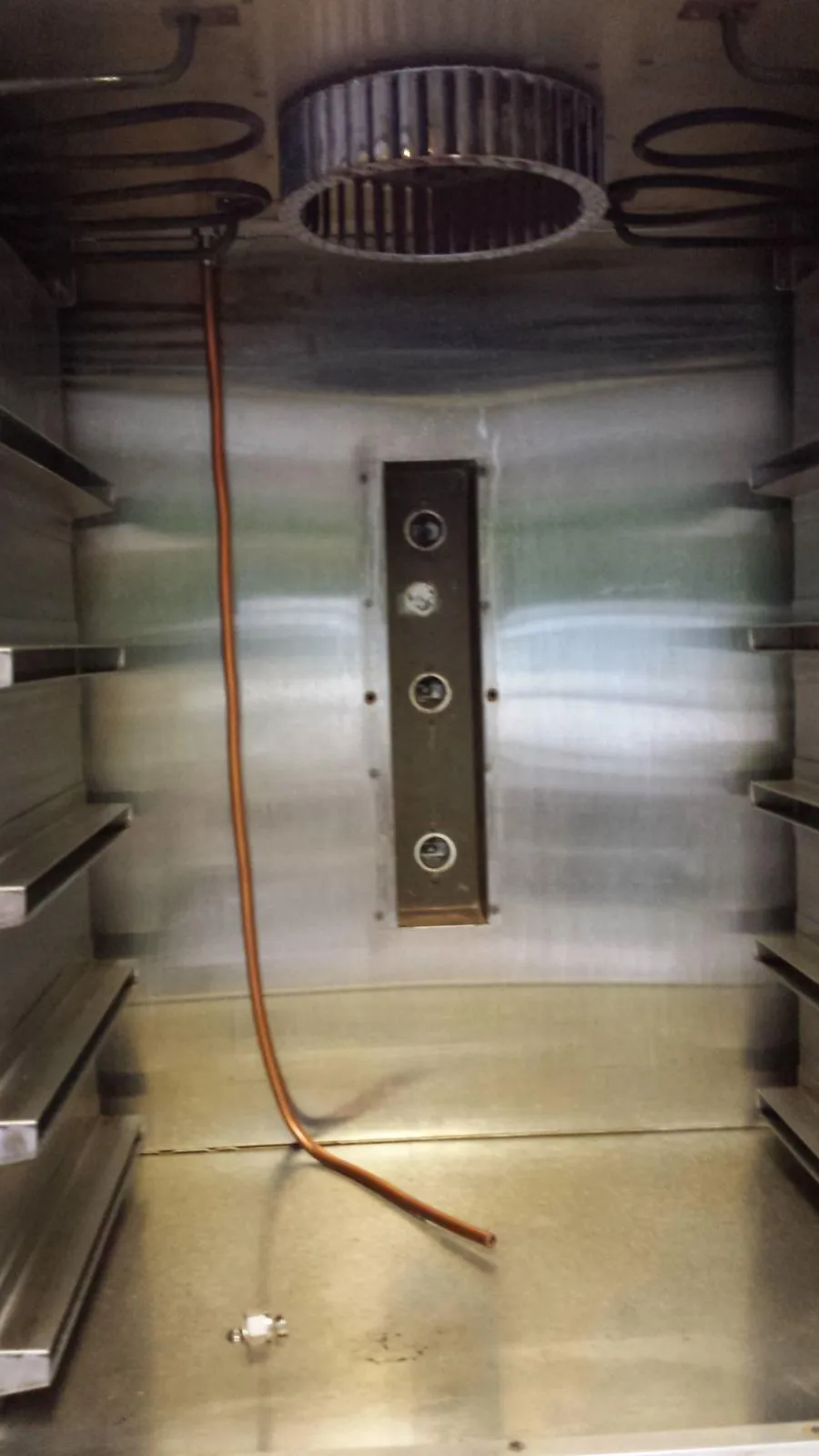

One of my ovens is a Lincat EC08 commercial fan oven with water injection - it's fairly crude - spray a jet of water into the backplate that separates the 2 element+fan units from the main oven cavity.

Note it's a fan oven and not a convection oven - this is a very standard type of electric oven in the UK - the fan(s) pull air in from the cavity, over the elements and sent it out from the back of the oven via a distribution system. There are no top/bottom elements in this oven.

I added 3 x 10mm steel plates into it - to use instead of the grids. I can cook 12 small loaves in one go (about 515g dough weight), or 6-9 larger ones depending on shape and size.

I can't run constant steam as it's a spring loaded button (I'd not want to either, it would cool down the oven considerably and end up flooding the place) so when I load the oven I give it a 10 seconds blast, then another blast a few minutes later if I remember.

Breads go in at 250C and I turn it down to about 210C after 12 minutes then give it another 22 minutes (a bit less for spelt) and that's that.

It's going to be hard to judge the optimum temperature for you - you'll have to do a few test bakes to find out what works best. I've found the 2-stage process works well for me for most sourdough breads - the lighter ones get baked a bit cooler - 200-210C. (e.g. buns, etc.)

Sounds a fun project - I'd love to add water injection to my other fan oven - although it shouldn't be hard - all the Lincat has as far as I can tell is a standard solenoid valve of the type you'd find in washing machines, etc.

-Gordon

Thanks for the info. I believe mine would probably be considered a fan oven as the elements are in the top under a stainless baffle (temporarily removed for the modification) which directs the air from the fan down the sides and out the channel as shown in photo. I am planning to inject steam by a steam generating machine rather than water. Not sure how that will affect the amount of time for adding steam

If you can inject steam then it won't need oven heat to turn it from water into steam - that's quite "high end" in oven terms (ie. expensive :)

Most of the commercial stuff I've seen rarely keeps the steam on for more than 10 minutes - by then the crust has formed and the bread will have sprung almost as much as it's going to.

I'm really interested in how this goes - keep us informed!

Cheers,

-Gordon

Send updates, Looks like a great idea. I am interested in the idea. Keep us informed!

This is a budget project. I got the oven which has a proofer on the bottom for $225 on craigslist. It came from Subway regional office. The have phased out the analog units. Seems to keep the temp accurately and pretty tight (+/- 18 degrees F) Steam generator is a Wagner unit for removing wallpaper. It was $48 from Amazon. It arrives today. So first bake will be this evening. Will keep updated. Thanks for all the info. So should we open the door and let the steam out after the initial 10 min?

Well it worked fairly well. We need to adjust the temperature and timing a little,but very pleased with the results. We did have one problem. We used normal aluminum baking sheets from a restaurant supply shop and raised the bread in the proofer then baked it on the same sheet moving it up to the oven and the bread was very stuck to it. How to avoid this? Have the pans already preheated in the oven and move the loaves from the proofer pans to the oven pans? any ideas

I never thought of using a wallpaper steamer as a steam generator though!

Use siliconised baking parchment in the trays to stop the dough sticking. You should be able to re-use it several times if you get good quality stuff.

Or get some silicone tray liners.

-Gordon

..with coarse corn meal. Or semolina. Or rice flour. For even better temperature control, it's definitely worth following Drogon's suggestion and introducing either thick steel sheets or cut stone slabs to give you more stability (and great baking surfaces for your bread). A short-handled flour-dusted baker's peel is the tried-and-trusted way of getting bread in and out without sticking - easy to make too.

Good luck and please keep us updated.

I use a piece of plywood cut to the width of the oven to load and unload - that way I can do a whole shelf at a time. I cleaned and sanded it and rounded off the leading edge. Low tech, but effective - I've seen other people use something similar for loading/unloading big deck ovens too.

-Gordon

..deck ovens. Sheets one-third or one quarter the width of the deck. Using something thicker than 12mm ply is sensible because it won't buckle.

Have you got any tips on getting steel baking sheets cut to fit? Things we all might need to be aware of?

The boards I made up are only 3mm ply. (I was what I had available without buying new - not broken so-far!) They're 520mm wide - the grid width is 530mm (GN 1/1) so they fit just inside the top guide of the channel that the grids or steel plates fit into. I made them 750mm deep so I can load up 2 shelves worth at a time, but getting the 2nd lot to slide is sometimes challenging, so most of the time I just load one shelf at a time.

I got a local engineering workshop to order the steel plates for me, ready cut - they said they could do them themselves but it would cost more than having them laser cut to size for me. I paid about £34 per sheet - 12mm thick mild steel, 530x320mm. They weight almost 17Kg each...

Picture here:

http://moorbakes.co.uk/wp-content/uploads/2015/04/oven.jpg

-Gordon

That looks really cool. So I do not think I can turn off the fan in my oven because the elements are behind a baffle and I don't think the oven will work correctly. My wife is concerned the blowing air will dry out the loaves, but I think with the steam injection it won't be an issue. Any thoughts?

She is wanting to get pieces of unglazed quarry tile to make the shelves. I like the idea of steel. We will see what we can come up with. And we will either make or buy a peel.

Here in the UK most new domestic ovens are fan ovens - that's the type where the element surrounds the fan and it blows hot air into the compartment.

they're a progression from fan assist - where there is a fan and often side elements or top/bottom elements.

It's a myth that fan ovens dry out food - however because they're more efficient than traditional electric or gas ovens with the hot air surrounding the food on all sides, what happens is that if cooks quicker, so you need to turn the temperature down - usually by about 10C. It's all about knowing how the oven works and cooks. My domestic fan oven is un-vented. Any steam generated by the cooking food more or less stays in the oven until I open the door. Most recipes these days will publish a different temperature for fan ovens now. e.g. see http://www.bbcgoodfood.com/conversion-guides

The Lincat commercial oven I have (2 fan + element unit) is vented. This annoys me as it's wasting heat - energy efficiency is not something commercial oven makers seem to care about )-:

In any case, I set my domestic one as high as it will go to heat up (250C), bake the loaves at that temperature for 10-12 minutes, then turn it down to 210C. I do the same with the Lincat, although that goes up to 300C - which I used to "season" the steel plates after covering them with oil...

-Gordon