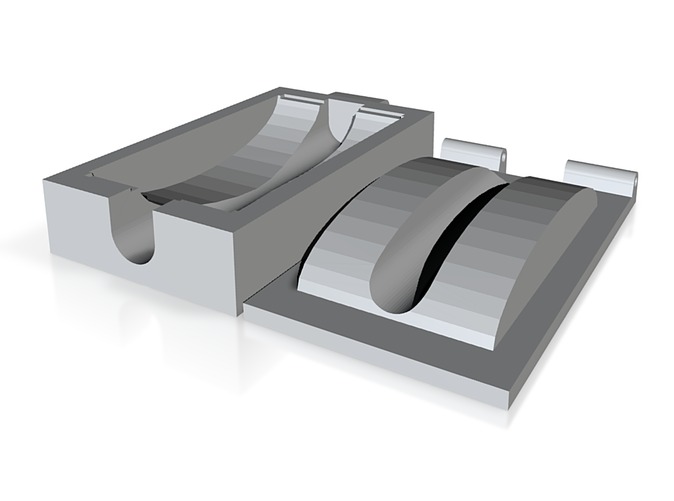

I got tired of cutting my fingers trying to get a double edge razor onto a wooden dowel. I remember Shapeways, which allows you to upload a 3D file and then they 3D print the object and send it to you. So, a few hours working in blender (blender.org), I came up with this:

It is still a work in progress. I just made this file today, so I haven't even had time to order it and fully test it.

It is designed as a clam shell. A metal pin will close the two halves together and act as a hinge. You set the razor blade in the notches in the top of the piece to the left, insert the dowel (up to 1/4" or 7mm in diameter) in the hole and close the top (the piece on the right). The top presses the blade down onto the dowel. You then open the top and remove the finished lame. At least in theory...

I'll post a detailed workup of this once I get it ordered. First I have to fix some thin wall issues with the hinges and re-upload.

I'm curious what everyone thinks of this!

I just made my my first so don't know if cutting oneself is a universal problem. But this looks great. And could be sold as part of the deluxe lame package.

I like it. I wonder if there is a way to design the lame so that it bends and holds the blade itself... without a separate "blade bender".

Riffing off your idea... one side of the clamshell could have an integral handle and the other (hinged) side clicks closed and bends/holds the lame. The clamshell sides don't need to be full width... just on the mid-line of the blade.

I just may have to learn the software myself!

I like it! Great idea!

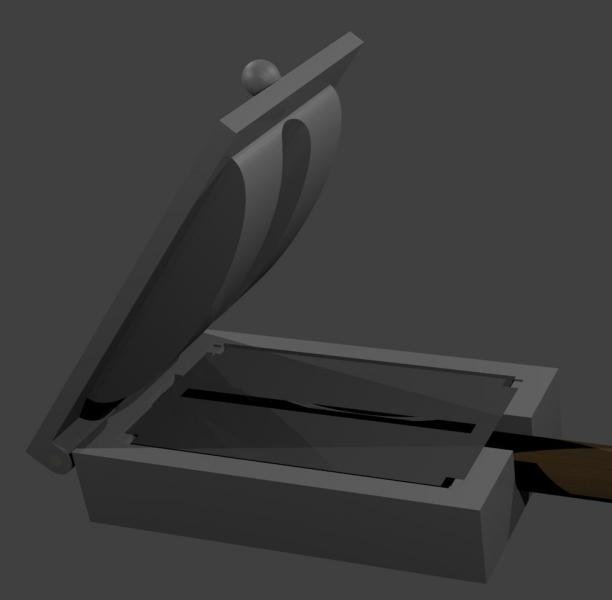

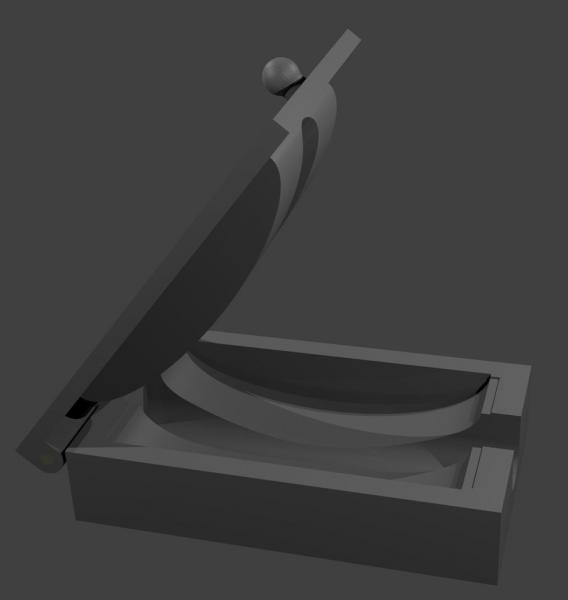

I updated the design a bit. It is much smoother now and the top has a little knob to pull on.

https://www.shapeways.com/model/1859355/lame-maker.html?li=search-results&materialId=90

Excellent use of 3D printing, I can't wait to see your finished product.

It will be a couple of weeks. No money. :(

I like the idea that Les Nightingill had. I'm not sure it is 3D printable though. I'm going to have to play around with it when I have the time.

It worked for the baking steel folks... Get people to invest in your idea for you.

That really wasn't my intention. I designed this for my use, but thought I would get input from others. I would be willing to open a Shapeways store for this item, if there is enough interest, but it covers such a small part of what is already a small niche market that I seriously doubt I could get funding.

I might be able to get a kitchen tool maker, like Oxo, or similar interested. Maybe.

Should have an adjustable curve. For scoring boules or other shapes where you want the cuts to open flat, the lame should be straight, ideally. For scoring baguettes and bâtards, where you want a flap of dough to rise and form an ear, you score at an angle with a curved blade, traditionally. It is easy to bend the razor blade to the desired shape if it is mounted on a thin metal handle.

There are some French lames with changeable blades mounted on a plastic handle but fitted in a bracket that is adjustable. I have no experience with that model. But I do prefer a lame the curve of which is adjustable, as described.

I don't see why your holder couldn't accommodate that sort of handle rather than a round dowel.

David

There is no reason is design wouldn't accommodate either a wooden or metal lame, right? Becsuse the only thing it is doing is bending the blade so thst whatever can fit through the hole can slide through the middle if the razor?

David, would a pro find this useful too?

Yes, as long as piece of metal can fit in the hole, and is narrow enough for the slit in the razor to fit over, this should work.

I don't know if a pro would find this useful, but I would imagine that having to fumble around with paper-thin razor blades with bare hands several times a day in order to make a tool to prepare food for public consumption is not a really great idea. Minimizing contact between the blade and hands can only be sanitary and safe.

Well, I'm not a professional baker. I really don't know how often professionals who are scoring hundreds of loaves each day change blades. I have the impression it is less often than you might think. I also have the impression that cuts from changing blades is not a big problem among professional bakers.

In regards to marketing, I think the OP's point about it being a minority of a niche is probably valid. What occurs to me is that the best approach would be to package the blade installer together with a handle and blades. My guess is that the whole bundle would have to be under $15 to attract many buyers.

David

on a chain or throw into a pocket!

The hinge could be a safety pin... or watch strap spindle.

This would be cool made out of clear acrylic.

If it clipped shut, might even be a good place to store the lame between use.

I really like the comments and ideas! Thanks everyone and keep 'em coming!

It is definitely small enough to go in your pocket and could easily be made into a key chain. I would just need to add a latch to the front of it to keep it closed. Not too hard.

I think the bundling idea that David has is very good, and probably the only way this could be marketed effectively. Still, how big of a market is this? A few hundred in the US and maybe a few thousand world wide?

I made this, quite honestly, because razors terrify me and forcing the blade onto a stick, something that the blade manufacturer never intended, requires my fingers to get too close to the edges. I have small paper cuts on my fingers. Heck, I shave with an electric razor. I have a feeling that too few share in my phobia to truly justify the time and expense to manufacture and sell this.

and switched to an electric razor decades ago to avoid serious bodily harm to myself.

I like the bundling idea because although this product might not appeal to professional bakers, it could appeal to the growing number of home cooks and gourmet chefs that are flooding stores like Sur La Table and Williams-Sonoma to buy premium tools and gadgets for their above average cuisine.

If you could get Oxo to produce them and then send out a few to the cooking classes held at Sur La Table and Williams-Sonoma for the teachers to use, you could get some decent sales.

In addition, if you sent a few to the TV show "The Chew" they would include it in a segment they have for new (and odd) kitchen gadgets which would get you a lot of exposure.

If none of this appeals to you then leaving access to the final design for those of us that might get 3D printers in the future would be appreciated.

These lames are dangerous to keep aroind uncovered. I think the deluxe lame package would sell. This is better than the plastic lame with cover.

Just to chime in as a professional baker of a decade plus, I can honestly say I have never cut my finger while putting a razor blade on a lame. Instead of struggling with wooden dowels and creating a new tool for making lames I would just buy a pack of lames that are made to accommodate razors. As long as you hold firmly you won't cut yourself.

And I switch the corner of the blade quite often. If I load a full oven of baguettes(around 120) I would switch halfway through. Especially for baguettes or any bread where I'm really concerned with precision.

one of those vitamin fizzy tablet bottles with a warning label, but still makes me nervous. And I get cut changing blades so I hesitate to use it.

I think this could be a gift item with something else, could even carry advertising or bread porn on the flat outside. I think it might get mixed up with a pencil sharpener or end up on a TV program "what*s this?" That first exemplar could earn you $500 if no one guesses its use.

Can also double as a cigarette extinguisher cube. (Have you seen those? Clever things, they look like a recycle material.)

Or just the opposite, a high end item, print in hard wax, centrifuged process a precious metal for a special busy person. jewelled, enamelled, engraved.

Can a 3-D printer print in hard teflon?

I put mine in a baby food jar, top shelf. I would love to have a snap on case to protect the edges, and if it also helped to slip a coffee stirrer into the blade, that would be a bonus!

I thought 3-D printing was only plastic. But once you have something in plastic it is a small step to have it molded for metal, for the baker that has everything!

I just got the go-ahead to buy my grain mill. The Mrs. decided that she overspent while away scrap booking, so she hopes that by my buying a grain mill, we'll be even. >sigh<

3D printers can do metal. it is typically powered metal melted via laser. Shapeways has many different metals available.

http://www.shapeways.com/materials?li=nav

I was just addressing the question referring to teflon, which IIRC is not an material available for 3D printers at this moment. That can change at amy moment, of course.

Actually, I was directing that at David Esq.

can only print in two types of plastic now, I have not heard of any that can do teflon (Yes there are also now 3D printers that can print food, but thats a whole different topic).

Such an item must come with an ivory-handled lame with a gemstone, preferably the baker's birthstone, mounted at the end in a platinum setting encircled with diamonds.

David

That would be the special limited edition Faberge Lame for Tiffany's and Cartier.

Sounds like a plan! I take it this is going to be funded by you?

You can certainly get bank financing once you show them your orders from Faberge, Tiffany's and Cartier!

David

and QVC might fund it 100%.

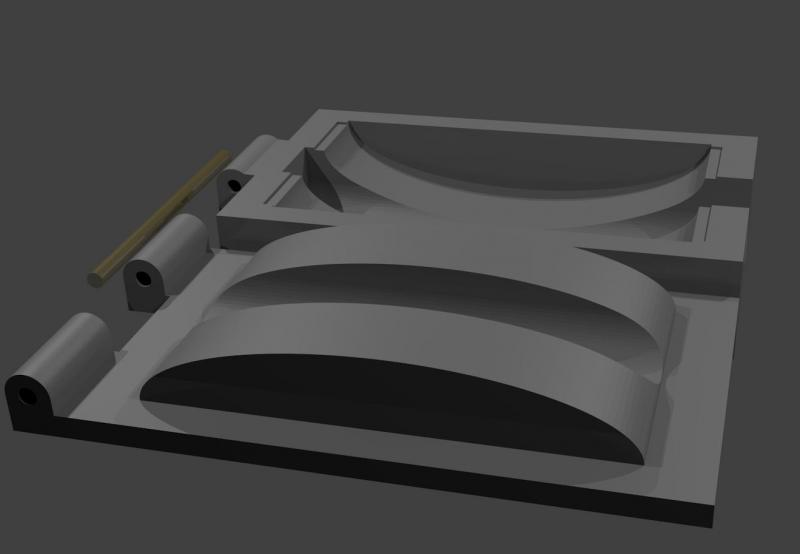

I made this from an old hack-saw blade, lemon-wood pruned piece and a little CAD work:

The CAD render-

This is how it turned out:

3D printing allows rapid prototyping helping to realize where dimensions are off and need adjustment. It is by no means a "go to market" placebo.

The safety razor blade dispenser does a pretty good job at preventing undo contact with the blades sharp edges. Careful yes, cut no.

I did a rather extensive market survey before copying in detail the best features from the best examples.

It works a charm and even has a few bite marks on the end where I clench it in my teeth when my hands are busy loading the oven...,

Wild-Yeast

It looks like an elegantly designed work of art to me with a nice handle to give it a more substantial grip. Well done.

Looks like MarkS and Susan (WildYeast) should get their products packaged together, throw in a few new blades to make it complete, and market them here on TFL for US to buy! I would certainly be interested, as I have not yet bought or contrived any kind of lame, and all my kitchen knives get dull too quickly for me to keep up sharpening them.

I also want to add a thought about materials. For the "Original Lame Builder", a 3D printed item will work fine. It should be ABS, have a latch to hold it closed, and be on a keychain. The lame handle would be either 3D printed or injection molded plastic as well. The packaging would include 3 to 5 blades. For the "Lame Builder Pro" I would suggest machined stainless steel. It would not be on a keychain. Instead, it would include a stand, which would hold the lame, the Lame Builder, and up to 30 (or 50?) blades in a safe position while not in use. And stainless (or a nice hardwood) would be used for the included lame handle. Packaging would include 10 to 15 high quality blades.

Wild-Yeast on TFL is not that Wild-Yeast Susan. Thanks for knowing the difference.

One thing that is easily overlooked is the fact that bakers (as a group) tend to be thrifty - hence the wide use of purloined Starbucks coffee stir sticks.

Plastic lame holders are great but soon suffer from the effects of hard carbon steel safety razors and will only need to be replaced. I desired something a bit more substantial than just another throw-away piece of plastic.

Besides, I like looking at it - it's an objet d'art...,

Wild-Yeast

Oops, that's what we get when we assume! Sorry, sorry, sorry, to both relevant parties!

I bow to you! You win this round! :D Very impressive! I think I'll make this instead. I have the tools and spare blade. Shouldn't be too difficult.

for me, just toss the three separate parts into a little mailer with a single page of instruction (drawings) No extra printed vacuum packaging to separate into recycle.

No wonder I cut myself, I'm putting the blade on wrong! (as seen in the above pictures) :)

Wild-Yeast, can you post specs on the metal part?

Wow...impressive thoughts and ingenuity, but what happened to simply being extremely careful?? My Wilkinson blades have dull tab ends that when pressed, bend to fit on my wooden skewer. I have never (knock on my head) come close to cutting myself. Just make sure to be calm, not in a hurry, and careful when handling the blade...OR, you can make this unique contraption and make us all jealous with envy :)

John

I try to be careful in everything I do, but, given the choice, I'd rather the tool be careful as well. There are times when I get into a hurry and don't realize that I'm taking (possibly dangerous) shortcuts. Then, there are people who have a much lower expectation of being careful to begin with, like my daughter. When I tell her to "be careful" and if she really tries hard, she is about as careful as I am when I'm in a hurry and not trying. Then, there are those that are just afraid of getting hurt and would never dream that being careful could be good enough to keep them from getting cut, burned, etc. So, bottom line, I want the contraption to be made, not so we can all be jealous, but that somebody might get to benefit by using it.