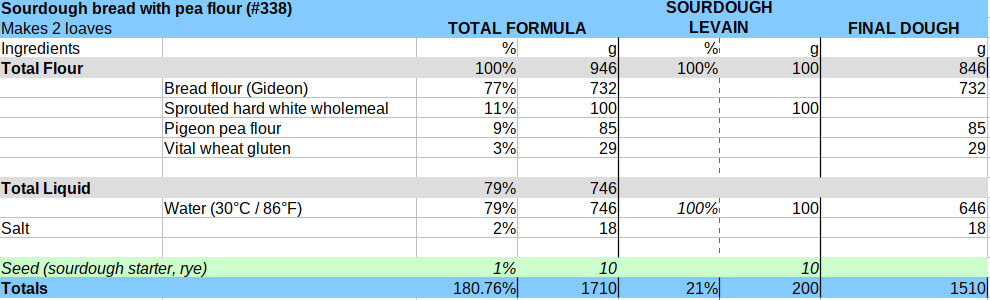

I recently bought some French Foricher T65 flour whilst shopping for some other flours.

I hadn't got a particular recipe in mind when I bought it, but then it became obvious that the first thing to try was an authentic "pain au levain".

I became rather interested in the original method for making pain au levain which dates from 1778 (or earlier) as detailed in Parmentier's "Le parfait boulanger, ou Traité complet sur la fabrication et le commerce du pain (Éd.1778)". The method is known as "travail sur trois levains", or work on three levains.

Basically it's a way of building up a levain in 3 stages and is similar in concept to the German Detmolder Dreistufenführung method for rye bread.

Anyway, I digress! The first thing I needed was a starter. Although I already had one, it seemed appropriate to make a proper French one - ie French flour, low hydration. A book from M. Calvel provided a suitable method, as detailed in this table:

I shrank the quantities down as detailed here and had a working starter in about 3 days. An interesting starter - 50% hydration and salted from the start (to reduce proteolysis).

So I went to on to make the pain au levain; sadly it wasn't that good! - rather bland and with a tight crumb.

I know it's heresy to say it, but I've decided I don't actually like T65 flour very much! It makes a sticky dough and I think it's too weak for sourdough use - best results I've had are with a poolish. Maybe it's just the brand I've used (though it's well respected....).

On the other hand, I've ended up with a great starter! - it has become my main starter and gives great rise and good flavour. Previously I could see my loaves spreading when I put them in the oven, but not now.

I usually do 3 levain builds - 4pm (1/1/0.5 25C), 10pm (1/6/3 25C) and a "booster" at 8am the morning after (1/1/0.5 29C), all salted at 1%. I do the builds with strong Manitoba flour to minimise gluten degradation.

I use the levain at about 33% of main flour with a minimal autolyse of about 10 minutes.

Not much to see in a starter (apart from those overflowing jar photos....), but here is mine when I'm taking a bit out to use - peeling back the crust (a bit like a bound lievito madre):

Only 30g in that jar - my normal weekly refresh.

And here's a loaf I made recently with this starter:

Lance