Hobart N50 restoration experience

As a followup to my original N50 thread: http://www.thefreshloaf.com/node/23049/n50-arrivednow-refurb

I'm reporting my experiences stripping down and refurshing my recently-acquired second-hand Hobart N50 mixer (which now will sit alongside my DLX2000). Hopefully it will be useful to anyone else taking this (not too difficult) project on. Unfortunately I didn't take any before pictures (lazy me!), but it was in somewhat beaten-up shape with well-worn paint over most of the base. A nice collection of photos of another person's strip and rebuild can be found here: http://www.flickr.com/photos/zug/sets/72157622051782719/

Parts were missing - the rubber feet, attachment cap and thumbscrew, no dough hook or beater attachment. The Hobart logo sticker was worn. The gear cover plate was warped. The bowl latch spring was broken. She did run, and run smoothly in all gears, but I had always bought it with the goal of a full tear down, repaint and rebuild.

The N50 service manual helped a little, but it is definitely doable without it. It has some useful tips, such as how to split the motor and transmission housings from each other and also how to adjust the transmission for smooth, quiet operation. The pictures/photos are also helpful. It's worthwhile having in additon to the parts diagrams freely available from Hobart.

Firstly, I ordered all of the missing / worn / broken parts. So far so good. As discussed in the thread above, I ordered some Morey synthetic 'blue' food grade grease (expensive - and incorrect - see below). During the strip down, which is mostly a methodical and logical process assuming you have the usual basic tools, patience and a modicum of mechanical knowledge, all went well. You will need some pin punches to drive out the various shaft pins. Other than that, no special equipment needed. The technique in the service manual of hitting the accessory hub attachment with a hammer in order to separate the motor housing from the gear housing is very worthwhile.

The most major problem in the rebuild occurred at this stage: having removed the motor from the housing, I accidentally dropped the housing on the concrete floor! It was immediately obviously dented - ouch! I completed the tear down, removed all of the old (brown, discoloured) grease from the gear housing and took all of the paintable parts to the powder coaters. There, we discovered that the motor housing wouldn't mate properly to the gear housing due to the dent. Popping across to the engineering shop, I thought all was a relief, as they managed to gently tap the housing back into what looked like was the correct shape, as it aligned and fitted once more to the gear housing. Whew (or so I thought). Got the bits back from the powder coaters, and the bowl lift handle back from the metal re-platers (it's nickle, in case you're interested). Also got some new decals printed using a Hobart logo online: http://en.wikipedia.org/wiki/File:Hobart_logo.svg

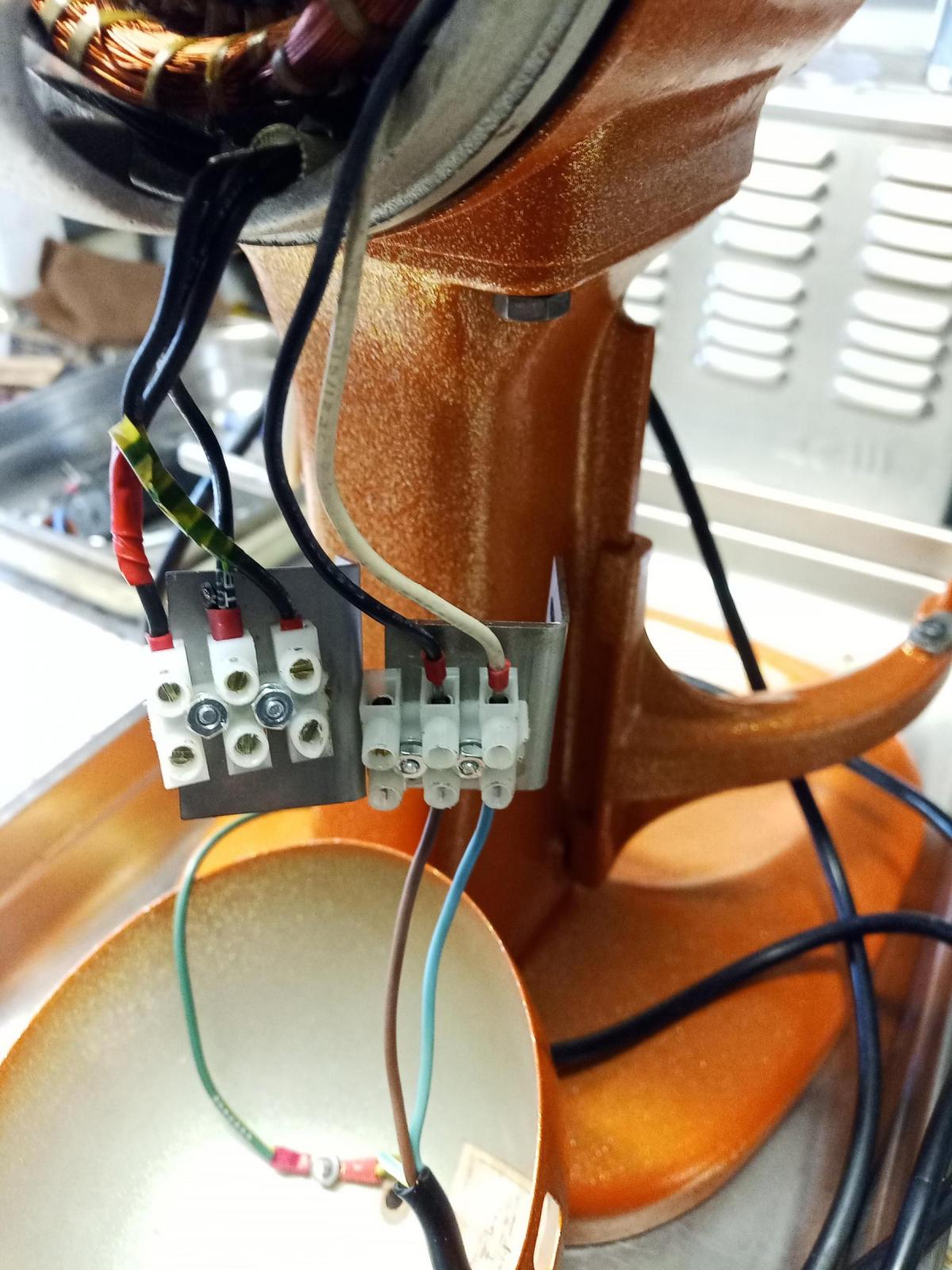

I then reassembled the gears and transmission and packed it with the Morey synthetic blue... some disgustingly sticky, tacky stuff. Now the real pain - the stator wouldn't fit into the still-distorted motor housing - arrrrgh! It's such a tight fit with no tolerance for variance. I tried filing the fins off the inside of the motor housing - and did get it to fit - but of course the rotor then wouldn't line up within it, while still rotating freely with the starter housing on. Realising that I would need a new stator housing was painful in the extreme - but that's what you get for dropping the most expensive piece of the mixer! Determined to see the project through I bit the large bullet and ordered a new housing which arrived in due course. I finally refitted the the motor and connected it all up. Hit the start switch to test... A loud "hummmmmm", but no rotation!! It turns out two problems were occurring:

1) The blue synthetic morey grease was just too tacky. Although it's a NLGI grade 2 viscocity (the correct one), it is extremely tacky stuff. Changing to a different synthtic but soapy-type grease (similar to the original stuff, but synthetic) - hooray!

2) The contacts on the start switch (not the on-off switch, but the switch at the rear of the housing) were not being adequately compressed. I'm not sure why this is, but I have managed to shim between the rotor and switch so that it turns on and off. It's a fine balance between the mixer turning on properly and having the contacts too close so they're shorting. One day I might take it to the local mixer service agent for a quick look, but for now it's working just fine.

[UPDATE 26/12/15: the problem with the starter motor was eventually traced to needing a shim (metal washer) on the shaft of the rotor, in the motor housing. Finally working this out had two advantages as the rotor is now correctly positioned a few mm's further to the rear of the mixer. One, the starter works first time, every time without shims. Two, the (17T) drive pinion doesn't strip the (49T) main gear. Don't ask how I found out this was the problem, except know that it cost two replacement main gears to figure out. To assist, the location of the shim sits at part #18 on this diagram: http://thesmartpartsestore.hobartservice.com/category/7939/motor-parts and is listed as "spring, loading" (SL-005-10).

For older model N50's, the location of the shim is at part #14 & 15 on this parts diagram: http://thesmartpartsestore.hobartservice.com/category/7926/motor-parts. Part numbers are WS-007-21 and/or WS-007-19.

I made the first batch of pizza dough and a sourdough bread with it yesterday - and it is a fantastic mixer. It's less work than my DLX2000 - in fact it's no work at all, in that I don't have to babysit the initial process to ensure ingredients are properly incorporating, or ensure the dough is still rotating around the bowl properly. I look forward to trying it out with drier pasta and bagel dough later this week.

As you can see from the photos below - it's a custom two-tone colour, since I couldn't be bothered getting the new motor housing poweder coated in the same colour as the other bits I'd gotten done. I like the effect, I've decided! The new motor housing also came with the warning plate attached, and has a larger bolt at the front corner - visible in the first picture - holding it onto the column (which necessitated tapping a larger 3/8th" hole into the column).

Overall, it's been a fun project (dropped housing notwithstanding). I've learnt a lot - and can now pull the mixer to bits in about 5-10 minutes.

Lookin' good. Congrats.

It looks like new. Hope that it runs that way too.

So now that you are done with it and can add up all the costs (except for the time spent and the enjoyment received) how did you fare relative to the cost of a new one?

It also looks like the cooling is all conduction via the stator and out to the case through the fins. Is that right? I guess that the grease carries some heat from the gears to the housing, but they are quite efficient so I expect that 90% of the heat is from the magnetic losses and coil resistance.

Yeah - it runs fine! Or at least as quiet / smooth as when I got it, which is OK by me.

This is especially good since the adjustment screw for the eccentric shaft was frozen in place (and made even more frozen by the powder coating). So, luckily I didn't have to adjust it in order to get the gears running quietly.

In terms of heat, it did two 900g pizza doughs one after the other (8-9 minutes each), and the motor housing was just barely warm. Yes, cooling is by simple conduction (and then radiation). And the 600g of grease in the housing is another decently-sized heat sink.

The only 'not perfect' aspect is when starting. Because the rotor is shimmed to the starting switch, sometimes it needs to be turned a few degrees by hand (via the planetary) in order for the starting contacts points to meet properly so the motor starts (rather than hums). As mentioned above I may get it looked at one day, but it really is a very minor issue.

Cost-wsie it was still cheaper than a new one... which is $5,000 here in NZ! I'm not sure how that price is justified given the strength of the USD/NZD, but there you go. I got the mixer second hand for $800NZD - they very rarely come up for sale here (although another went for $400 a month later on our largest online auction site - sigh!). The new stator housing was $1300NZD - *ouch*. The price of parts for these mixers is, I suppose, governed by the lack of OEM parts and the strict distribution channels Hobart is able to maintain. They're a bit like Stihl chainsaws in that regard.

I suspect I could have saved a few dollars by asking a friend/relative in the US to obtain the housing from Hobart USA and then shipping it here privately. I did have an option to purchase another second hand N50 for less than this price, but at the end of the day, I didn't want to tear down a working N50 just to scavenge it for parts - a bit sentimental, I know. I'd also set my sights of restroring this one - and if you've ever done car restoration (as I have) - it's a labour of love and doesn't make any financial sense! In a blatant act of self-justification - all up it cost about $2800 NZD - still much cheaper than a new one AND I now have the equivalent of a diploma in N50 servicing. And do you know the price of tertiary education these days? :)

As a last query, the new bowl spring latch I received from Hobart doesn't quite seem to hold the bowl as tightly as I remember it being on my brother's kitchen aid Pro. It doesn't "click" into place. I've attached a photo below. To those who have an N50 - how tight is the fit on yours? It looks to me as thought the spring is about 3mm too short.

[UPDATE 21/7/11] The top right-angled part of the spring latch broke off cleanly this morning, through where the red line is on the photo below, when I bumped the bowl lip on it. Although initially annoying, it has allowed the two screws to be properly tightened, and now the spring latch sits lower and operates perfectly - yay!! Interestingly, the part is illustrated without this top piece in the Hobart catalog.]

As a further followup, I managed to locate a couple of photos of the mixer before I started on it. Although it doesn't look too bad in these, it was quite rough around the edges and the photos belied the fact that it wasn't just a quick powder coat of the base.

I saw your posts on WACEM and I am so pleased you was able to restore this workhorse! Congratulations!

Hi,

Just happened on your site, as I'm looking to regrease my N-50 as well.

Your machine looks great - nice job !

I know it's been a while but I have a few questions if that's ok . . .

1. Do you remember what you ended up using for grease, if the Morey grease didn't work out so well ?

2. Also, I'm pretty sure I'll have to re-grease the planetary gears. But for the gear-box - do you get to that going in from the back ?

3. I take it you just went by the exploded parts diagrams, right ? AFAIK, the manuals are not made available by Hobart.

4. Did you have to do any special adjustments - gear shimming and the like - to get it back running smoothly ?

Thanks a lot if you have a moment.

Kent

San Francisco

1. Update 25/12/15: Mobil FM222 Foodgrease is very similar to Hobart OEM, and what I now use/recommend in my N50.

2. No - through the side cover (behind the gear selector lever) is the easiest way to push in some fresh grease for a top up. For a full exchange of grease however, you'll need to dissassemble the whole mixer and scoop out all of the old grease from the transmission housing (that's the front half, as opposed to the motor housing, which is the rear half).

3. Yes - but after I was nearly done, I got access to the N50 service manual which makes life easier. Private message me if you want me to email you.

4. No - without the maual, I wasn't sure of clearances. Further, one of the adjustment screws was stuck in place, and I never bothered to use an extractor to free it. With the manual, there is a good guide to the amount of shimming you need to achieve the factory-spec and also a good guide to "tuning" it so the gears run as smoothly as possible. Luckily, mine runs smoothly despite the above!

hello Breadman_NZ

I just wanted to say thanks a bunch for your different posts on various sites regarding the refurbishing of an n50. I recently purchased an n50 as a Christmas present for my girlfriend. She really wants a kitchenaid, but yeah, I'm not getting a new one, and after doing some internetting, it seems like the n50 is the way to go for a heavy duty 5qt.

It is a 1954 model and still works wonderfully, actually. It came with a kitchenaid bowl, so I went ahead and purchased the '256' spiral hook for it like you recommended on another site, as well as the hobart EDDdough-005 whatever it is spiral hook. the hobart hook has not come in just yet.

my quest now is to search for and hunt down all the gorgeous metal attachments by kitchenaid and hobart for this thing. can't wait to surprise her with it all, haha.

I took lots of tips from others, and learned a lot, so share and share alike! The Flickr site with the photos of another N50 restoration were really nice, but it seems it's been turned into a private album now, sadly.

It's great to read you've got such an old N50 up for restoration - 48 years old. Not many kitchen appliances can claim that sort of longievity, especially one that works as hard as a dough kneader. Gotta love commercial gear. You will NOT regret the N50 over a domestic KA, in my opinion. Effortless power.

The #12 hub of the A120 and larger mixers has a far larger, more commercial range of attachments available - although the #10 hub of the N50 is compatible with the cheaper (and more cheaply made in general) KA attahments, which is good in its own way.

I've got my eye on this N50 metal mincer attachment ... seems to be very good quality: http://www.ebay.com/itm/NEW-Meat-Grinder-Food-Chopper-attachment-for-Hobart-N50-c100-ce100-Mixer-/160868917213?pt=LH_DefaultDomain_0&hash=item257488dfdd

If you get the above mincer, I'd be keen to know how you find it, since I'll probably get it (at some point over the next few years).

I may get that grinder. I am for right now trying to get it to knead and operate perfectly in terms of the heights and what not. with the 256 dough hook it struggles to get the mix going at the bottom when using small amounts. the majority of the size of baking that we do is like, 1/2 cup of starter , 1/2 cup of water, and 1 1/2 cups of flour. it makes enough for a nice small round that is perfect sized for the two of us. I practiced with that mixture amount and the 256 hook wouldn't even get it going, haha. So one of two things needs to happen. the first is that I need to wait until the hobart hook arrives, and try that out, and the second is I might need to get more used to mixing up more batches of dough.

I have no idea what i'm doing. I will admit that. But as an engineer, I know that starting with quality equipment and tooling is the best way forward, so that's why I went with this little hobart.

So far I have ordered the spring clip for the back of the bowl (on the lift mechanism), new rubber feet, and a kitchenaid whisk and flat beater for this thing.

One thing I am really interested in finding would be a pastry knife for this guy. It looks like they are pretty rare, and were only really on the early model G kitchenaids and the early hobart n50's. It doesn't look too different from a flat beater though.. Maybe I could cut down parts of the flat beater to turn it into a pastry knife? Taking off one side of it and those horizontal braces could turn it into a makeshift pastry knife...

Once I figure out how to get the regular dough kneading going I will start moving forward with getting attachments that also work for it. Thanks for the link, I might just give that very grinder a try.

Yup - I had the same problem to a greater or lesser degree with all of the hooks. Here's the solution:

1. Use the beater to bring the dough together - about 30 seconds or so. You might want to give a quick mix by hand or pulse the mixer on and off for 1/2 second pulses to prevent flour from spraying everywhere.

2. Once you've done the above, switch to the hook and knead away.

If you manage to source a pastry knife, let me know! :)

Is the pastry knife no longer available from hobart? I have a part number for it, but I am not sure whether or not it will even still be available.

The pastry knife for the N50 has not been available for many many years. Hobart still has them for other larger mixers.

Back when I was actively buying KA and Hobart mixers for my collection, you could buy a pastry knife for $20 or so on Ebay. I was able to buy one for each of my two chrome model G mixers without any trouble at all. A pastry knife came with my Hobart N50.

I think I am partly to blame for the scarcity of the pastry knives. I touted them so much on the old Kitchenaid Mixer forum that they became popular. Those that have them now, won't let them go.

Now............they are few and far between and cost a fortune.

I had the opportunity to come across something else that caught my eye on your website!!!

it's the copper insert you speak of!

How will this help baking, or is it only good for when whipping up eggs? Will it help with cookies and pies and stuff? From what I can tell anything involving egg whites or sugar and it will whip up much better?

It was discontinued in 1979, even though it's listed as a part number on various websites.

Here is the grinder I ended up buying.

New old stock Aluminium / Steel hobart-kitchenaid food grinder.

I think i'm going to get the 'new school' pasta press attachment for it.

A grinder almost like that came with My old KA Model G Commercial mixer. Except the tray is slightly smaller & round & there's no pusher! Do you know where I can get a wooden pusher?

Hi

Iv'e just bought a n50 and looking to overhaul I know this post is quite old but I would really appreciate a service manual to make sure I do things properly . if anyone can help me out that would be great .

thx

Sure thing - send me a PM.

thx for quick response, not sure how you pm on here, cant seem to find it ?

Hi. Do you still have a copy of the service manual? Would you be a able to email me a copy?

mass.mail.box@gmail.com

Ps. The larger bold hole in the motor housing you mentioned is to accommodate a interlock switch of the EU model

(not sure if you knew this, might be useful)

Send me a private message via the forum tools.

Not even sure how to do that...

I can't find a private message option/button anywhere!

It can be troublesome. Email Floydm (the maintainer of this site) and he will hopefully sort you out...consider it a little test to see if you'll be capable of tearing down the N50 once you get the service manual ;)

Sorry, I don't see how I can do that? I have already stripped down and rebuilt my gearbox. I was hoping the manual would give a little help tuning the gears. I didn't think this was a right of passage type of thing.

It would be great if you could help , but if not, I understand.

Was joking. It's not a rite of passage, but I don't wish to post the link in a public forum.

Email floydm (floydm@thefreshloaf.com) and ask for private message function to be activated for you. To send a PM, click on any thread poster's username (i.e. "breadman_nz" just to the left of this message), then click on "send this user a private message" in the page which opens. Good luck!

I'm going to purchase the Mobile Mobil FM222 Foodgrease on Amazon. I've been studying my N50 to determine the problem with the Transmission. The planetary action on the beater and the power #10 drive quits. I've determined that it doesn't appear to be any of the bevel gears or drive pins (that I can see) Floyd sent me a beautiful mechanical drawing and I've been cleaning all the grease out to determine exactly what I'm up against. I want to order out the grease to have it on and when I get the repairs made. How man cartridges did you use greasing your N50? both on the planetary section and the transmission section? thank you, george young

The manual calls for 20 oz of Shell Darina #2 grease, which is no longer available. For those of you in countries with sensible numbers, this is 566 grams.

The slipping planetary and attachment hub is likely caused by a slip between the hub bevel gear and lower planetary shaft. In my case it was because the pin which links these two had jumped out of its notch.

George,

I purchase two tubes of Mobile FM222 Food Grease. I used a tube and 1/4, I think I could have packed in a little more if I tried. Floyd please share the drawing or let know if has been posted. Thanks!

@ratatouille . . .

That's very generous of you to go to all the trouble of tracking down the venerable N-50 for your girlfriend.

Myself, years ago when my grandmother passed on and all her stuff was divvied up amongst family, I said the only thing I really wanted was the N-50. It's gotten a lot of use ever since, and nice memories as well.

One thing . . . how do I say this . . .

re : " She really wants a kitchenaid, but yeah, I'm not getting a new one,"

As I'm sure you know, we engineer types and guys in general love machinery. But from what I've seen, not all women are quite so entranced with the idea of industrial machinery, if you get my drift. So if she's really got her heart set on something new and sleek, and perhaps expecting it, I'd hate to see you in an awkward moment when she opens her Christmas present. She'll most likely end up loving it, but have you thought about how you're going to present and explain that vaunted baking wonder ? You know, just so she isn't awkwardly crestfallen, with you not being quite as appreciated as you deserve - but instead she realizes what a great gift she's getting. ;-)

Maybe she's a machinery nut, I don't know.

It's funny, I've had several female housemates over the years, and almost every one of them has put a nice piece of fabric over the TV in their room, should they have one. Most males just don't seem to mind. Just an observation.

Good luck with your project !

Kent

I'm lucky my wife likes (or at least tolerates) my whims of having large, over-engineered commercial-style gear in the kitchen. It fits our "buy once, buy right" mentality along with recycling second-hand stuff and having that stuff be repairable/restorable rather than disposable.

... at least that's how I'd be selling it to your better half! As WE know, having an N50 will make you the envy of your mates and those in the know.

I have ALWAYS believed in the philosophy that you buy the best once! Not only in mixers, but in other kitchen appliances.

That is why I have a Robot Coupe R2 Food Processor rather than a Cuisinart! And I like buying the commercial small appliances that have lived in commercial kitchens for my home. Why buy something new when you can have something even better for the same or less money?

In my group of girl friends, we all have this philosophy. I don't think it is a male thing.

So I'm slightly confused now.

After reading this page:

http://leoladysw.blogspot.com/

It looks like the kitchenaid model G and hobart n50 parts and pieces are interchangeable when it comes to beaters/whips/hooks, but the regular kitchenaid K5A / K5SS style attachments won't necessarily work because the depths are off. Is there truth to this? What kind of dimensional differences do we have?

I don't believe my hobart N50 is using the correct bowl with it; honestly I have no idea what bowl it has. Here are some photos of it.

Should I get the correct bowl? Will this thing fit the kitchenaid bowl with it or the hobart bowl with it better?

http://www.ebay.com/itm/New-Metro-Design-Beater-Blade-for-5-Quart-KitchenAid-Bowl-Lift-Mixers-White-/200824266209?pt=Small_Kitchen_Appliances_US&hash=...

That's a beautiful vintage nameplate, switch and gear lever - I assume you're going to clean those up and reuse, rather than buying new bits? The new ones aren't as stylish as those old ones by a long shot!

I have a model 4749 just like yours, even has the "vent" hole in the front of the base. I have attached a picture of the nameplate. I have started to dig into it and have found four bushings (see picture) that are for the threaded studs or the screws. I am trying to locate these on a schematic. I do have a parts list for this model but can't locate them Any help would be appreciated. Thanks!

Hello,

If I'm not wrong these bushings are located behind the stator (when you look it from the rear of the machine). They are mandatory to stop the stator at its right place, but are no more longer present on recent N50 since the stator is stopped by the housing itself.

Regards

Makes sense that they are stops for the stator. My concern is that someone put them in there without good reason since I did not see it any the parts schematic. Thanks!

Looks like you've got the KA bowl, K5ASBP(https://www.amazon.com/gp/product/B00004SGFU/ref=oh_aui_detailpage_o02_s00?ie=UTF8&psc=1). The proper Hobart part number bowl is SST005, which has a flat lip, rather than a rolled one (https://www.amazon.com/Hobart-BOWL-SST005-Bowl-N50-Mixer/dp/B007RZLCK8).

I've only ever had the Kitchen Aid bowls for my N50 and they are fine.

As for the attachments, I recommend getting the proper N50 attachments (Beater-ALU005, DWhip-SST005 and spiral dough hook EDDOUGH-ALU005). The KA dough hooks don't quite work as well as the N50 parts as the sizes are a touch off.

Is a Kitchenaid bowl. You can tell by the top rim being enclosed. This is not a NSF approved bowl like the N50 would have. But for home use, it does not matter and makes absolutely no difference. I am Leoladysw and the blog you quoted is my own blog.

What happens if i use regular K5A based attachments for it? I believe the height will be incorrect as I need to get hobart n50 / kitchenaid Model G specific attachments such as dough hook / beater / whisk ?

You are correct. The 5A attachments will be too short and too narrow compared to the N50 attachments.

I can confirm that. I have both an N-50 and a Kitchenaid K5-SS.

The bowls appear to be exactly the same size - although the N-50 bowl has the flange lip. The K5-SS bowl works fine on the N-50 with the N-50 attachments though.

But the N-50 attachments are about 5/8" longer, so they couldn't be used on the K5-SS - they would interfere at the bottom of the bowl. I tried it.

Conversely, the K5-SS attachments work on the N-50, but then there's ~5/8" more of gap at the bottom.

I guess the K5-SS pulls the bowl up just that much higher, so its own attachments work without too much of a gap.

The attachment widths appear to be about the same, at least for the whisk and mixer paddle.

Wow, that is awesome! You have quite an amazing site, I would like to say thanks for all the wonderful information :)

Thank you, for visiting my blog. I am glad you like it.

By the way, a Kitchenaid bowl spring latch fits perfectly on this 1954 N50. The one I ordered is this:

http://www.ebay.com/itm/120985618341?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1497.l2649

Based on possibly breadman_nz's recommendation!

breadman_nz :

When you put grease into the gearbox through the gear lever opening, did you more or less fill it up ?

Btw, for anyone else doing this without a grease-gun, one way to try is to partially fill a freezer zip-lock bag, close it, then snip one of the bottom corners to create a poor man's pastry decorating cone.

ps: I got your pm - replied - thanks very much.

Yep - just keep pushing it in there. It would be damn near impossible to over grease it. Although with a grease gun, you could get more in, any excess is going to ooze back out the gearbox cover anyway.

One thing I noticed is that the '54 N50 has two little zerk fittings for oil to be added every couple of uses in addition to requiring grease. One at the front right near the PTO, one at the rear at the round casing on the back. I am not sure what kind of oil to put in it, do I have to call hobart on this one, or does anyone know?

You beat me to it - I was going to ask the same question today.

The 1983 Hobart service manual recommends Emergol HLP-68 (which I think is a mispelling of Energol HLP-68) - for motor bearings, motor bearing wick, and thumb screw. That's the only mention of "oil".

Btw, are those motor sleeve bearings . . . ball bearings ? or just bushing bearings - anyone know ?

Another old N-50 manual recommends 3 drops of oil in each fitting, once a month.

"Energol HLP-68" is a BP owned brand of mineral based hydraulic fluid with antiwear additives.

It's generally used for bearing, gear, hydraulic systems, variable speed changers, etc.

As far as viscosity, it's more or less equivalent to SAE 80W Gear oil, or SAE 20 Engine oil . I would think that if you can't find the right hydraulic fluid, the gear oil would be the better choice - more on that in a minute.

Btw, here are some tables with equivalents :

I happen to have some Kal-Gard SAE20 motorcycle fork oil - which is a hydraulic oil - w/ molybdenum additive for anti-wear - so I might use that. But I don't think that particular oil is made anymore.

That's the short answer - now for a little explanation, probably putting way to fine a point on it. But I was curious so I looked up a few things. If someone has a better short answer I'd like to know. Somehow I doubt it's really all that critical.

=======================================================

re: HLP-68

HLP oil is a classification of Hydraulic Oil - meaning a mineral oil based type, and the "P" means "antiwear additives".

See http://www.hk-hydraulik.com/en/hydraulics-encyclopaedia/hydraulic-liquids

The "68" part is a viscosity rating from the ISO viscosity rating system, which rates oils for performance at 40°C.

There are equivalents in the SAE system - see the chart here :

http://www.bobistheoilguy.com/viscosity-charts/

You can see the line from ISO 68 (at the left) lining up with SAE 20 Engine Oil and SAE 80W Gear Oil

on the right.

Engine oil has a different scale from Gear oil - so you can see that Gear oil SAE 80w is about equivalent, actually,

to SAE 20 Engine Oil. (It's not equivalent to SAE 80 Engine oil.)

About Engine Oil vs Gear Oil :

Engine Oil lubrication basically relies on a thin film of oil developed by an oil pump.

But gears don't normally have pumped oil, so they use oil w/ special additives to handle the more extreme pressures they endure.

I'm thinking if you can't find hydraulic oil, use gear oil, as we don't have pumped oil pressure in the N-50.

See : http://www.amsoil.com/articlespr/2007/article_gearoilbasics.aspx

The "W" in SAE 80W stands for "Winter" - a designation for oils whose viscosity is measured at low temperatures (not 40°C). So SAE 80W means that in low temps, the oil performs like Gear oil SAE 80 at the normal higher temp. So it's actually lower viscosity than SAE 80 to be able to perform like it - at lower temps. I think I got that right. ;-)

See : http://www.upmpg.com/tech_articles/motoroil_viscosity/

That's the back story - if anyone comes up with a great oil solution, I'd like to know.

I've done a bit of oil research myself in my motorsports engineering days, and you're pretty much spot on with everything regarding the oil viscosities! However I would like to make a small clarification regarding the famous W number, and how confusing it is/can be.

The W means a couple of things sort of. The W is associated with -18c. No letter is associated with 100c , only the SAE designation.

Quote from S. Peterson on BobistheOilGuy ( Another great oil forum for oil enthusiasts; oil : bobistheoilguy :: bread : thefreshloaf;

"

If there is only one number (SAE 20) it means the lubricant viscosity falls within the viscosity band for 20 weight oil at 100°C (212°F), sometimes called the summer classification.

If there is a number followed by the letter W (SAE 20W) it means the lubricant falls within the viscosity band for 20 weight oil at -18°C (0°F), sometimes called the winter classification.

There is a band or range of acceptable viscosity for each viscosity weight or grade at each temperature. Sometimes liquid lubricants meet both the lower winter and the higher summer viscosity requirements, and carry numbers such as SAE 10W-30. SAE 10W-30 means that at -18°C (0°F) the oil viscosity falls within the 10 weight band, and at 100°C (212°F) the oil viscosity falls within the 30 weight band. Such lubricants are called multi-viscosity lubricants, and are made by adding specially selected VI improvers to 10 weight oil.

"

Another great site, KEWengineering.co.uk has this chart to show the temperature grade relationships between SAE 5W, SAE 40, and SAE5W40

My kitchen is never going to be -18c, and I hope this little N50 never sees 100C !!

Thanks for that . . . I'd wondered what temp "W" is associated with. So it's -18c or 0°F.

I didn't actually get time to look around on bobsyouruncle's site, or whatever it is . . . bobistheoilguy.com - but there's really a lot of info there.

That last link on my post above has a pretty good discussion of that too :

Motor Oil Viscosity Grades Explained in Layman's Terms

http://www.upmpg.com/tech_articles/motoroil_viscosity/

Having said all that . . . what to do ?

I was going to use my Kal-Gard SAE20 motorcycle fork oil - w/ molybdenum - but shied away from that because I couldn't bring myself to put black oil on that wick.

So I have some SAE30 hydraulic jack oil, took out the wick, and put a few drops in there just to hold it over.

It was pretty dry and probably hasn't been oiled in a million years.

I doubt the SAE30 is really going to cause any problems.

I think it's just a sleeve/bushing type bearing in there.

When I get the right thing I can flush it out.

Curious, what are you thinking of ?

I have yet to disassemble this guy, so I don't know what sort of condition it is. For the motor bearings and everything, i will probably use this:

http://www.globalindustrial.com/p/tools/degreasers-lubricants/lubricants-food-grade/tri-flow-synthetic-food-grade-oil-iso-68-1-4-oz-tube?utm_source=go...

For the grease I will probably use the mobil gearbox grease spec'd per Hobart.

I've actually contacted mixed up jake to see if they'd like to do a sort of vintage resto collab on it.

The Hobart EDDOUGH-ALU005 arrived, and is almost exactly 5/8" longer like you guys said! I will mix up some dough (even though I do not have an oven in the homewood suites... hmm, i wonder if i tip the girl who makes breakfast if she'd bake a loaf of bread i make up and then leave it in my room while i'm at work.. hahahaha!!!

I will make a video of it kneading up some dough, and maybe you guys can tell me if everything sounds / looks good??

I also ordered the hobart flat beater and the whisk from wasserstrom as well, so hopefully we will have the basic stuff on the way. I'm really also looking at the pasta press attachment as well as the traditional pasta roller and ravioli maker..

SO MANY ATTACHMENTS TO GET, OMG, it's like a choose your own adventure!!!!!!

This thing works a squillion times better than the KNS256BDH! Especially for small amounts of dough like I have been testing with. It kneads like a boss, but does seem like it starts to climb up the dough hook just a little bit. I didn't notice any climbing with the 256BDH.

I have NO idea what I'm doing! Seriously! Is my girlfriend going to be just as lost with one of these mixers?

I also had the chance to whip up some eggs. OMG. wow. this thing is like cheating. haha.

My reconditioned n-50 makes a bit of noise on fast speed ,if I pull the shift lever gently toward 2nd speed the noise is reduced a great deal . It is a newer model with the large on/off and shift plate , is there an adjustment that can be made , the machine looks the same as your machine breadman. I rarely use speed 3 but would adjust it if it were not a teardown issue. G Gage

:)

heck yeahhhhhhh

After a wonderful conference call with MixedUpJake, I've decided to move forward with that project as well! This n50 is going to get the full on Hobart /MixedUpJake retro refurb done to it, complete witha custom paint job and what not... Can't wait to share details with it...

Well, I guess I should post that the mixer has arrived at MixedUpJake / Hobart! They have received it two days after I shipped it! Go UPS! I sent it along with the pastry knife, aluminium spiral hobart dough hook, aluminium hobart flat beater , and a stainless steel bowl.

I asked them to please have Hobart Technician go over it and adjust it for use with the flat beaters etc so that nothing hits, and if necessarry, get any new hardware/components/genuine hobart bowls/etc in order to make it as good as it can be. The last thing I want to do is break this pastry knife!!

The concept for now is going to be kept secret, but as the date moves closer I will share it with you guys :) :) :)

Some hooks, whisks and blades are interchangeable with the bowl-lift, narrow bowl 'heavy duty' or 'professional' KA's. The bowl itself is too. However, your mileage will definitely vary - and with the relatively modest price of the proper dough hook (ED-ALU005), whisk and beater, you might as well get them - they really are delightfully solid chunks of aluminium! The catalog I linked to below also lists the correct part numbers for the attachments.

There is a plastic space in the bowl lift mechanism, in the column of the mixer (part illustrated as number 32, on page 6, 00-241-764, arm - bowl lift) as seen at this parts catalog: http://hobart.co.kr/manual_pdf//022.pdf

I don't know how long it's been plastic, but it doesn't really have any bearing on the rest of the mixer, and seems appropriately engineered for its location and purpose. There is no perceived cheapness or weakness in an N50!

@ breadman_nz (or anyone else actually)

When you did your rebuild, did you notice any ball bearings in the machine ?

I have some kind of noise in my N-50 that sounds very much like a dry ball bearing.

( However when the machine is really working hard you actually don't hear it because there is enough back pressure or force on the gear train to take up any slack, thus there's virtually no vibration that would be creating noise. )

Otherwise it's pretty loud, but the machine does run well and gets all three speeds.

Back there when we were having the grease and oil discussion I pushed some of the "flung" grease in the gearbox back on to the gears themselves, but that didn't seem to stop that dry-bearing type noise. I thought all or almost all of the bearings were sleeve bearings.

Also I regreased the plantetary gears.

I think either I'm going to have to buy some grease and really fill up the gearbox, or take the whole thing apart and find out what's running dry.

Btw, that gearbox is really supposed to be filled up with grease ?

Any thoughts ?

There are no ball bearings, only sleeve bearings.

Mine makes a little rattling noise like dry bearings, but I don't worry about it too much, especially since all looked well when I was last in there a few weeks ago.

The rattle is probably due to slight maladjustment of the gears, or wear and tear of the gears, bearings or washers and spacers - will take a tear down and inspection and replacement of any worn parts and readjustment to factory specs. to be sure. The service manual gives a good sequence for adjusting the gears to minimise noise in each of the gears, but one of my adjusters is stuck, so I haven't bothered.

It's quite quick (like 5 minutes) to get the front half and rear half of the mixer apart to properly inspect and regrease (assuming nothing is seized). Grease capacity is listed in the manual as "20fl oz." of Darina #2 grease. To get it in there I'd recommend either a wooden spatula to poke it all the way down, or a grease gun with a flexible hose. It's a dry sump, so no oil, just lots of grease!

Thanks very much breadman !

That answered all my questions and more.

Mine is really making much too loud a rattling noise - as you say, probably an adjustment and/or needs more grease.

But since it doesn't sound like it's too big a deal to open it up, and I have the manual, I think I'll do it.

I've rebuilt a couple of auto transmissions before so hopefully I'm up to it.

Just like being a kid again and taking apart mom's toaster to see if I can get it back together again.

Hi kbarb-if you have the sevice manual would you care to share it ? I have a parts maual already .

PM me.

We were having that discussion back in October about grease . . . .

So I was looking to buy some KitchenAid grease (part# 4176597) on Amazon, but a reviewer there (the first review) recommends Tri-Flow Synthetic H1 Food Grease (Tri-Flow stock number TF22021).

See :

Amazon page for KitchenAid grease 4176597 - first review

Amazon page for Tri-Flow Synthetic Grease

The Triflow product is a PTFE (teflon) grease and the application is described as "Use on gaskets, O-rings, conveyors, sterilizer chains, slides, pool equipment, electric motors, water filters, and universal joints."

But I don't see anything there about gears, which endure higher forces.

I can't seem to find anything about it's wear resistance properties.

Any of you have any thoughts on that ?

It does seem like it might work.

Awesome rebuild here!

I have an N50, it's awesome. I use it for Pizza dough. Most likely will do some bread at some point as well.

Does anyonw know if this Ice Cream Maker attachment will work?

http://www.amazon.com/gp/product/B0002IES80/ref=as_li_ss_tl?ie=UTF8&tag=savcenwitsen-20&linkCode=as2&camp=217145&creative=399369&creativeASIN=B0002IES80

I need to get mine apart to clean it out and regrease it. Is there a procedure outlined anywhere? The pix on Flikr didn't really help me figure out how to get it apart.

Sometmes it makes a little noise like it needs a gear lash adjustment, so I'd like to give it a clean, grease, and adjustment.

Yes, that mixer/attachment will almost certainly will fit an N50. Seems to get good reviews - if you get it for your N50, let us know how it goes - I might get one!

Send me a private message if you want the N50 service manual, but the basic procedure to get the front half off to allow proper regreasing is:

1. Unplug mixer

2. Remove the rear cover and take of the starter cage (4 small nuts)

3. Use a long shaft large flat blade screw driver to undo the 7 bolts holding the two halves of the mixer together.

4. Take off the side cover (the one the gear lever sticks out of)

5. Gently disengage the gear lever from the internal cam - it should be obvious how - and note how it goes back together

6. Now you can separate the two halves of the mixer body. Place a rag over the attachment hub and tap over the top of the hub with a rubber mallet, which should separate the two pieces (don't let it drop!).

7. Scoop out / wash out grease and replace with new stuff. If you're keen, by all means fiddle with the gears and washers.

8. Reassemble in reverse order

Good luck!

Thanx for that description. That's not at all how I thought it came apart!

I bought and installed the KA KICA0WH Ice Cream Maker attachment. Willmake some ice cream in the next few days.

Here's the Link.

http://youtu.be/ZC1TQ3GLhy8

I also posted a thread about The Ice Cream Maker

http://www.thefreshloaf.com/node/33701/hobart-n50-kitchenaid-ice-cream-maker-attachment-compatability

I have both a N-50G and a KitchenAid (Hobart) K5-A and will take some more accurate measurements to ascertain exactly why agitators are not compatible but bowls are.

I have deternimed the bowl lift pillars are in fact the same lenghts.

So it is either the bowl lift mechanish itself has a longer throw (range of travel) or the output shaft on the bottom of the planetry is positioned higher.

If I can actually find my Bosch laser level, I should be able to tell pretty easily by putting them side-by-side.

I've just reread the thread but I'm still unsure what bearing oil to use. I went with the Mobil Food Machinery Grease from Ebay but I'm still lost on what bearing oil to get any help would be great.

I use triflow, in my front and rear oil ports simply because I have it on hand. Seems to work just fine, I ber sewing machine oil would be great.

Are these ports just on certain models? I am looking everywhere and can't find any on mine? Thanks in advance! Sorry for the noob questions.

After my latest rebuild, I went with the Mobil FM222 foodgrease for the transmission grease. It's very close in appearance and feel to the Hobart grease, and seems to be doing the job just fine.

For the oil requirements e.g. the oil in the wick / rear motor bearing, just use 3 in 1 sewing machine oil, or 20w/50 - it's not really critical.

Greetings new member but long time lurker! Could someone show where is this wick people speak of? I just re packed new grease in mine but did not change or add any oil? Just greased shafts and bushings so now am worried that I should oil these instead? would like to get the motor and bearings oiled if need be. Thanks!!

When you take the rear end cover off, revealing the starter apparatus, you can't miss the string wick. It's sitting in a little bowl, just above the rear brass bearing. Apply a few drops of SAE30 motor oil or 80w gear oil to it (for more see the posts above: http://www.thefreshloaf.com/comment/231188#comment-231188)

I thought that only the KA Commercial Model G had the lubricating wick at the back of the motor!

Nah - my 1980's N50 has that exact string wick.

Sure thing, send me a private message.

How do we private message in this forum? I'd like to message you to ask for the N50 service manual but I can't figure it out.

Thanks...

Hmmm....looks like the private message function is broken - at least on my broswer (Firefox 44.0, under linux). All I get is a blank page when I click on any username from these threads.

However, you can still post a PM by going to your messages, and sending a 'new message', and then searching for the username of the person you want to PM. I'm sure there used to be a single button / link to do this more easily.

PM sent to you....

I'm not able to view private messages either--when I click the link in the email I got that said I received a private message, it said "Access Denied - You Are Not Authorized to View This Webpage". I'm logged in...

I'm confused.

Should be fixed now. I emailed Floyd on your behalf.

You can Google it & send it to the printer like I did. Or go to Restaurant Supplies, look for the mixer there, scroll down a ittle & to the right, you should see it Follow the PDF & print it.

The shims are to minimise end play (or end 'float' as it's sometimes called). There shouldn't be any on the rotor, basically, but it still needs to turn freely. If you have no in-out play on your rotor, the shims are probably fine.

The shaft pin should tap out easily, although with the angle, it's a bit tricky to get a longer center punch into it. Either a) it's jammed in there tight or; b) you're hitting in the wrong (fat) tapered end. Try tapping on it from the other side. Also, remove the screw first and try loosening (or removing) the pinion gear, as the pin is to secure/stop the pinion from rotating on the rotor shaft, rather than holding it in place as such.

Re: the stator - yep, trying to get a local rewind sounds best if possible. Lord knows I've spent plenty on my N50 hobby! If the windings are bad, the motor will run weakly if at all, and may well have trouble getting started.

Hi All, Just bought a what I assume to be a very old N50. It looks like the one ratatouille posted above (same model # as well 4749). It does run a little rough, so I'm going to try cracking it open to take a look at the gearing. breadman_nz, I saw you have a copy of the service manual, could you PM that to me as well when you can?

FYI, I don't see any PM features on the site, but I just registered, so I'm assuming I need to be activated by the admin?

Thanks!

PM sent. Yeah - when I clicked on your username, it just brings up a bunch of blank boxes, with no option to "send this user a private message". Not sure if it's a setting on your account that needs to be tweaked or activated, or if we just don't know how to PM properly :)

Perhaps email / contact floydm who is the board admin.

It's much appreciated. Perhaps I need to send a few posts before it activates, I've seen message boards that do this. I better get posting!

Mike

Hi,

Saw your rebuild....very nice. I am going to acquire an N50 that needs some work. I was going to just repair it but I would to consider the powder coating. Can you share contact info for this service and cost?

Well worth powder coating it if you're already doing a thorough tear down and regrease - should look good for years!

It was a few years ago now, but I recall paying a couple hundred for the local powder coating shop to strip and coat all the external metal parts (base, column, starter motor cover, motor housing and transmission case). I'm in NZ though, so what I paid will be well different for you, I suspect!

Only minor caveat is that the powder coating affects the fit of a few parts, so you ll need to sand/remove it in a few places (e.g the column and bowl lift) - nothing major.

Go for it!

I anyone can part with a, N50 drip cup please let me know, or if you know of any source that has a reasonable price please also forward information.

So I recently purchased an old rugged looking N-50, plugged it in and got the buzz or hum that you wrote about. I took it apart, removed old grease, inspected the planetary, tumbler and agitator shaft unit and all gears look fine. Determined that the problem must be in the motor section, so started to take that side apart. Had some questions arise as I am working on it and that lead me to find your posting. Q1. started to remove the pinion gear and noticed that behind it was some cotton string, looks like cotton butchers twine, was this installed by the factory? Does it soak up oil? Q2. I have played with the rear start switch and I think that is the problem. I have plugged in the mixer and turned it on and looked to see if the start switch moves, it does not. How did you know your start switch was bad? What did you look for and is there a way to test it? I don't want to buy one if I don't have too, is it possible to just short the switch to see if the motor works? Q3. I found a copy of the service manual online it has 22 pages, is this the entire document? Thank you for your post and answers,

The hum problem may well not be in the motor section - if the transmission / gears are too tight, because for example you've got the wrong grease in there, the motor can't get rotating to start (and will hum).

If the contact points of the starter itself are wrongly gapped or dirty, the motor won't start (and will hum).

Q1: there is no string in that location, so someone has added something, or a fibre washer has gone seriously misshapen. There is a small bit of sting/wick in the start motor housing (where the starter switch is located), which is oiled to keep the oilite bearinglubed.

Q2: I don't actually think my start switch was bad now, more that the rotor was too far forward, and needed to be shimmed. I've copied this from my post above:

The location of the shim is at part #14 & 15 on this Hobart parts diagram: http://thesmartpartsestore.hobartservice.com/category/7926/motor-parts. Part numbers are WS-007-21 and/or WS-007-19.

As you hold the rotor in your left hand, the shim/washer slides onto the shaft of the rotor. The rotor then slides into place into the housing, and you secure it using the shaft pin, pinion gear and screw on the other side of the motor housing face i.e. the side which faces the transmission.

You need to find a shim/washer about the right thickness - too thick and the rotor won't turn freely. Too thin and there will be too much in-out/forward-back play in the rotor (there should be hardly any). Or you could order the official parts as listed above!

Q3: The 2002 service manual has 22 pages. You should be good.

I removed the motor from the stand and the gear case, shorted the power switch and the rear start switch. Plugged it in and it started to run after I gave the rotor shaft a spin with my hand. It ran well but I noticed that the case got really really hot. I took the stator out and it looks really charred.

I am now waiting on some grease to come in from my online order and I will reassemble it and see what happens when I add the load to the motor.

Do you have any experience working with a motor that is charred and over heating? Do I need a recoil or replacement?

Thanks for you sharing your experience.

Hmmm. I'd be worried about a charred motor that gets hot just running....sounds like too much resistance in the winding > heat. The case gets war, but it shouldn't get really, really hot after running for a few minutes with no load (i.e. disconnected from the transmission as you have done).

You can by new rotors / stators, but it'd be preferable given the cost to at least consult a local motor rewinder. Good luck!

A single phase induction motor which rotates only when it's started by hand has one or more problems with current supply to start-windings and/or the start-windings themselves.

The Hobart N50's motor is designed to start without the need of a capacitor, but the drawback is that its start-windings are quite fragile and may burn in few seconds if they are still powered after the rotor began to revolve (this is precisely the job of the centrifugal switch which cuts start-windings current, and should never be shorted in order to work reliably).

Would you take a picture of the rear of your stator please ?

If you are sure that all electrical connections are correctly done, then I'm afraid that you must take the stator apart and bring it to a rewind shop for a full rewinding ... :-/

question on the powdercoating, how did you get the motor out of the sleeve, or didnt you? service manual doesn't really say one way or another. i have my machine stripped ready for powdercoating just not sure on removing the stator from the casing.

You have to take the stator out of its housing prior to powdercoating. It's pretty simple to remove, just undo the small nuts on the long bolts which fix it to the housing. It may be a bit sticky to remove if it's been in there for years, but it should pull right out.

is there an easy way to get all the grease from the the gearbox, ive dug the majority of it out but i cant figure out how to degrease the remainder for power prep.

No easy way, sorry - that's why it's called elbow grease! Get in there with fingers & a rag and scoop it all out. Get into the nooks and crannies with a rag-wrapped screw driver or similar.

Finish with a solvent cleaner to get the residual grease off, although I suspect that would be part of the powder coating prep that the shop would do.

Thanks to all who have posted information on the N50. Just got done with a rebuild. This is how I came about the N50. Christmas 2014 our (23 year old) Kitchenaid 5 quart mixer broke down (the wife put cold butter to mix with sugar but won't own up to it). I replaced the armature and stator - problem solved, Christmas 2015 we decided to upgrade to an 8 quart Kitchenaid, got a great deal through work with Whirlpool partners. An ad for a broken N50 came up in February on C.L, best thing it was local. I offered our working 5 quart Kitchenaid plus $80 for a trade, the seller (very reasonable) agreed. I spent the next two months taking the N50 apart with help of the Fresh Loaf and parts schematic. I sand blasted the housing, base, and pedestal ($125). The failed part was the tumbler yoke, all the gears, armature, and stator were in excellent condition. For the re-assembly I added a circuit breaker, stainless steel socket head cap screws in place of the hex bolts, stainless Phillips head screws for the control plate, Mobil FM222 grease, and a beefy stainless steel accessory cover. Thanks to all! Still looking for another N50, I did enjoy the rebuild.

That is one sweet honey-nut restoration - great work!

The switch cover plat is a really interesting shape - I've never seen an 'L-shape' cutout like that. It's almost as though the transmission case is a different era from the motor housing. Do you know, from the serial number, when the mixer was made?

My personal sense of aesthetic suggests the decal should be higher on the gear lever side. Oh, and you've got a screw missing on the switch plate ;)

Again, great job!

I have been digging through the web and have not found another model with the "L" shape cut-out. I thought it was just another iteration. The switch plate does have an extra hole that the "L" shape housing does not have, thats why there is no screw there. The machine is running great! I will be offering this mixer up for sale, and offering another N50 that is in great shape, but the base could use a powder coat and I will be installing a new cord. Not sure if N50s came with a ground plug cord, or the cord was replaced with a non-ground plug cord. I am in the northern Illinois suburbs if anyone should be interested in one of these N50s. They will go up in about a week.

Just clarification in my post: I sandblasted the parts with free access to a sandblaster and cost to powder coat in Crystal Lake , Illinois was $125 for all the parts.

Where did you get the SS cover for the accessory take off?

I modeled the two parts on CAD and have a connection to a machine shop which already uses stainless. I can post the detail drawings or can get an estimate from a paying machine shop as well.

WOW, OK. That makes sense now. Don't bother with the machine shop quote, it's not that big a deal to me. I thought maybe you found something to re purpose for it.

You had the Labels made? Or are they decals?

They are decals purchased from Ebay.

Hello all,

If anyone can please help locating a pdf, bitmap, any other type of file that contains the old vintage Hobart logo label. For my first rebuild I was able to buy the rectangular labels from Ebay. With the 2nd rebuild I would like to stay true to the original but I will need to have the label printed but need a source file. I did locate a rebuild on beevo.org but there is no contact info. Not sure if the poster is on the fresh loaf. See link for pictures of his rebuild. Any help on the label is greatly appreciated.

http://www.beevo.org/HobartN50/

Didn't take long just was not doing the proper search. I found a file with logo, will attach it here if anyone needs it.

Hello,

Unfortunately these labels are not compliant at all with the original vintage logotype ! Please fell free to send me a picture of the original one and I will reproduce it for you as a vectorized file.

Regards

Flormont,

Here are the pictures. Your help is greatly appreciated.

Flormont,

Here are the pictures. Your help is greatly appreciated.

Hello and thank you for these photos. But please could you send me a pm with the 2nd one enlarged ? For a nice job I really need to zoom over all tiny details :)

Regards

Hello, I was wondering if I could get a copy decal file you remade to original specs, the picture above is the only one I can find of the vintage style, thank you for your help.

Brian F,

You can have the label file. I had to order a minimum quantity of labels, since I have some extra (if you are in the states) I could send you two labels for $6.00 to help cover the cost of the labels and mailing. If you are not in the states, let me know where you at? I am sure we can work something out. Same offer for anyone else that is looking for vintage labels.

Awesome, sounds great, I am in southern California. Please send an email to whitedoverestoration@gmail.com and we can work out shipping location and payment. Thank you very much.

Excellent job.

First of all: there is more involved in the dis-assembly of the N50 than the Kitchenaids. The Kicthenaids are very simple to work on and you take it apart in in ten minutes, clean the grease out in 30 minutes, then re-grease / assemble it together in 20 minutes. I can turn my planetary shaft clockwise by hand and also get a clicking sound (I think this is normal - others please confirm). I think a gear is just ratcheting by another gear by turning the planetary shaft by hand this, but has no ill effect. The planetary shaft turns counter-clockwise under power which is the intended normal operation. If this is all that you are experiencing I would suggest to leave it alone and not dis-assemble it. If you do decide to go through the be-build you will need common tools: box wrench, flat and Phillips screwdriver, hammer and punches, circ-ring tool and a gear puller to separate the rear shaft from the armature. It would also help to have the Hobart part number list and schematic handy, post it note pad and baggies to bag and tag all the parts with contents and part number and number the bags then check off the part number list as you bag and tag parts.

Keep us updated, will help as much as I can. What part of the country (or which country) are you in?

Regarding the beater touching the bottom of the bowl: Your shaft may have dropped down due to slippage or a failed component. You should not have to take the gear transmission apart to fix this. You will need to work on the planetary assembly and inspect your parts there. This will require accessing the six or eight screws that goes through the motor housing and gear housing to get to the planetary housing.

Any experience of HL6 vs N50?

...a couple of other possibilities for the beater touching the bottom of the bowl are a worn notch on the beater itself, allowing it to sit a little low. And we're presuming the bowl is the correct one. Or that the bowl lift isn't lifting a little too high.

In my experience you don't need a gear puller to fully disassemble the N50, but other than that I agree with givemethedough.

In the southern hemisphere N50's also rotate counter-clockwise, unless your starter switch is somehow out of adjustment, in which case I have observed my N50 rotate the opposite way(!). My N50 also clicks when the shaft is rotated counterclockwise. It's not a worry, and nor is a touch of gear lash unless you really want to get jiggy with shims.

@JohnCa: PM me if you want a PDF of the service manual

Thanks

We so need a disassembly Video!

(See post from breadman_NZ from June 8, 2016) I re-posted my reply, was not sure if it was seen or not?

I have been digging through the web and have not found another model with the "L" shape cut-out. I thought it was just another iteration. The switch plate does have an extra hole that the "L" shape housing does not have, that is why there is no screw there. The machine is running great! I will be offering this mixer up for sale, and offering another N50 that is in great shape, but the base could use a powder coat and I will be installing a new cord. Not sure if N50s came with a ground plug cord, or the cord was replaced with a non-ground plug cord. I am in the northern Illinois suburbs if anyone should be interested in one of these N50s. They will go up in about a week.

Hello,

There is no big mystery about this "L" shaped plate ... :-) Since the N50 mixer is made since many decades, if you accurately look at the variations across the time then you will notice that the left-upper corner of the motor & gear housings have been redesigned.

Old design, small control plate :

New design, large control plate :

In conclusion, your mixer had some thing wrong with the gearbox or gearcase and the original one has been replaced with an older one. After this mix, the control plate has been machined in order to fit the old-designed gear housing.

Flormont,

Thanks for showing both. Your reply makes sense, it may explain why the transmission (except for the shifter yoke) was in excellent condition. Even though it is from an older model it may have seen very little use. The mating surfaces between transmission and motor housing are so perfect I figured they were built for each other from the start..

The fresh loaf is an excellent website, a wealth of information. Thanks again!

You're welcome :)

It seems that many parts of the Model G / early N50 / late N50 are interchangeable, indeed.

However I don't know exactly why the motor & gear housings have been redesigned with more curved surfaces. My guess is to reduce manufacturing costs, or maybe to make the cleaning easier.

Regards

Just posted an N50 for sale (video is also posted), please spread the word if you know of anyone that is in the market. Thanks!

If you can stomach the quite amazing price of $105 for a new drip cup:

http://thesmartpartsestore.hobartservice.com/category/18526/planetary

EDIT Jan 2020: Ouch - the cup is now $176 !!

That is quite a steep price, I would rather buy groceries. I will seek other alternatives, I will keep all of you posted if I am successful. Thanks!

For some reason I am unable to PM you. I would be interested in your cad drawing for the stainless nose cone and plug. It is a very cool mod.

Did you fill in the vent hole in the front of the machine? I am curious what the point is of it. I would believe that there is ample space around the entire base for air to enter the column.

Thanks

The vent hole is need, if you should plug in an attachment and then try remove it my guess is you could get it out but it might create a seal in the inside of the hub. Should I just post the drawings here?

I can't seem to PM either without posting my full email address in the open. I will dig the drawings out. In the meantime if any of you guys are interested in bidding the Red N50, its up for auction right now (on that famous four letter site that starts with an "e"). Need to fund an anniversary trip, there will be other rebuilds to come but only one 25th anniversary. "Life is journey, not a destination" - Ralph Waldo Emerson

Hello! Just wondering if you can tell me anything about the rarity of the C100 in red? I see you listed your red N50 on that auction site, so I was hoping you had knowledge on things of that nature... Cheers!

Hello, The red C100 is not mine. There is red N50 on Xbay that appears to be a spray can job (my guess) certainly not powder coated. Its selling for an arm and a leg, I can't even command that price for a powder coated rebuild. My first red rebuild is on here if you scroll up. I did buy a red factory red N50 (that is pictured here with other rebuilds) through an online XXXgo site. The colors are far and few between than the common battleship gray. I am holding on to the red N50 for good, it is in excellent condition. Hope this helps answer your question.

I will figure a way without posting our emails to the world.

The hole I was speaking about is the one in the front of the base. At least mine has one with s brass collar . It's about 1/2 inch in diameter and I have no idea what the purpose it is there for.

Good luck on the sale and trip

Hi all,

I've been reading all your Hobart N50 restoration experiences and I've decided to launch my own project. I expect to give one of those real beauties to my wife ;) Please pardon my bad English as I'm from France!

I've searched and found two old used Hobart here in France. I've asked to the sellers to send me a video. Here is the first that was sent me: https://youtu.be/ds90bQfuWcE (I'm still waiting for the second to compare)

I'm not an expert, and it seems to me that that particular copy has a strange sound when comparing to other videos. What would you say? Do you think that this copy is damaged and not worth buying?

If you think that it can be fixed, I think that I will offer to the seller something like ~450€. Does it sound like a good price for you?

Thanks very much in advance for your help, I can't wait to get my hands on a good copy of those and start restoring it!

Sounds OK to me and looks and starts smoothly.The noise in second and 3rd speed sounds like gear lash, which is nothing major and may be able to be adjusted to reduce. 1st speed sounds good.

It's definitely an older model (pre-1980's), but that doesn't matter, as parts are still available.

As to whether it's worth 450 euro, is hard to say from the other side of the world - not sure what the demand-supply of these is like over there!

I agree the motor sounds fine. The other noise is from the transmission, additionally the grease that it has may not be at its prime anymore and not as agile as fresh grease. I am sure you will hear less of the back lash once you have replaced the grease. As for price; having a bowl and attachments should be a factor in the askn price.

Hi @breadman_nz and @givemethedough, Thank you so much for your fast answers! I'm impressed!

I'll send to the seller a 400€ proposition. Seems like a good price regarding the general state of it.

I'll keep you updated on my project ;)

Bonsoir Limezy,

Pas grand chose à ajouter aux réponse que nos amis vous ont déjà donné :-)

Le bruit constaté pourra surement être atténué par une révision de la boite de vitesses et une tentative de réglage du jeu fonctionnel entre les différents pignons, mais il n'y a rien de sûr pour ce modèle vraiment très ancien qui a surement déjà pas mal d'heures de vol (l'ancienneté se voit bien à la forme général des carters de tête, ainsi que les arrêtes saillantes de la colonne). Quoi qu'il en soit cela ne l'empêchera pas de continuer à tourner, le plus important étant que le moteur démarre de façon franche et systématique (il faudra bien vérifier que le coupleur centrifuge est encore en état de fonctionner longtemps).

Pour le prix proposé, j'espère que cela suppose que le batteur est complet avec tous ces accessoires cependant. Prenez garde si vous envisagez une restauration ou un dépannage, les pièces détachées Hobart coutent très cher chez nous en france, hélas. Bon succès dans votre acquisition.

Préface J'utilise un traducteur en ligne.

Salutations à nos amis français. Vous envisagez d'ajouter un cordon d'alimentation muni d'une fiche de mise à la terre et d'ajouter un disjoncteur pour empêcher le moteur et le stator de surcharger. Comme mentionné dans le dernier post remplacement composants sont très chers de Hobart. Dans un sujet non lié; Je suis reseaching hébergement à Paris. Où pensez-vous que je peux passer 6 jours sur le budget d'un travailleur. Toutes les suggestions sont les bienvenues. Je vous remercie.

Hi Givemethedough,

Thanks very much for your comment.

Concerning the circuit breaker, do you have any experience with adding one to an Hobart N50? Could you send me photos or schemes? I'm not sure that everything will fit under the carter.

For your stay in Paris, you can search on AirB** they have a lot of good offers! If you're on a budget, you can find hotels on cities around Paris like Versailles (south) or Asnières (north) and use the suburb trains.

Limezy,

Yes I have added breaker switches to the N50. The photos will show the location, the specifications are: 6amp (you could go to 4amp but I was concerned with false tripping), push button thermal, 32v DC (not sure what your wall sockets are putting out), Reset method: Type 3 manual reset, Mount type: 1/4" quick connect blade.

Bonjour Flormont,

C'est un plaisir de savoir que d'autres compatriotes arpentent ce forum et utilisent des batteurs Hobart! Puis-je vous demander comment je peux contrôler le coupleur centrifuge lors de l'achat? Ce batteur semble effectivement assez ancien mais il a été très peu utilisé, d'après le vendeur. Il ne lui manque que le crochet, ce qui ne semble pas être un très gros problème vu l'offre que l'on trouve sur internet.

Avez-vous vous-même une expérience en restauration de batteur Hobart? Je suis intéressé par des retours, notamment sur le thermolaquage (faut-il boucher certains trous, donner des consignes particulières... ) et sur le câblage électrique (Givemethedough me propose de mettre un disjoncteur et une fiche terre... Y a-t-il assez de place dans le carter?)

Concernant votre mise en garde, je pense faire plus une révision complète assortie d'un sablage - thermolaquage qu'un dépannage. Je n’achèterai pas de robot qui ne tourne pas parfaitement à l'allumage, ce qui m'obligerait à chercher des pièces détachées...

Hello again,

If you are referring to the on and off switch and speed lever, then yes I have seen where these two components do not align as when they were new. In order for the on and off switch to properly move there is a sheet metal piece that must slide into a cut out in the speed shifter. The intent of this mechanism is to prevent shifting speeds while the mixer is operating. In the pictures below I have added a new alternate switch and eliminated the sliding sheet metal component. The only thing with this arrangement I will have to remember not to switch speeds while the mixer is in operation or I may do damage to the transmission.

Hi all,

Please allow me to ask another question about the Hobart that I'm likely to buy.

The seller sent me a photo of the identification plate http://de-ruffray.fr/index.php/s/4eW2k6fCKajE55T

That plate indicates: ML16472-M. Do you know that model? I can't find any of that reference on https://my.hobartcorp.com/resourcecenter/Pages/PartsCatalogs.aspx or on http://thesmartpartsestore.hobartservice.com/store/shopforparts.

Thanks!

Hi all,

I'm quite embarrassed to beg your help again!

I've recieved the video from the second Hobart seller here in France. I'm a bit helpless because it looks better and newer (the first one was from 64, that one from 85) but it has a horrible sound...Here are the links:

Hobart "1"

Photos: http://de-ruffray.fr/index.php/apps/gallery/s/NS0g1ltQWmJzqQ8, Video: https://youtu.be/ds90bQfuWcE

Hobart "2"

Photos: http://de-ruffray.fr/index.php/apps/gallery/s/w7IDxu9fU8UuqaU, Video: https://youtu.be/M91pJxwfoYw

Which of both would you advise me to buy? Thank you very very much for your help!

The second, newer Hobart also has gear lash noise. Similar comments to those above i.e. it doesn't affect the function of the mixer, and can likely be adjusted out with shims and using the adjustment screws as per the service manual.

Difficult to know which of the two to get - but in reality either would be fine. The older N50 may look older, but that's just cosmetic and could easily be tidied up with a fresh powder coating.

Both of these look like good machines, but I like Hobart "1". As long along as they are operational is the first order, which ever one you can get the best price on.

Hi all,

I've just bought the "1st Hobart" from my list just above. It should arrive home within two or three days! Waiting for it, I have bought some pin punches as advised, found and red the official service manual from Hobart. In addition of that, I've studied the photos from "Zug" on Flickr. Really interesting! However, I hope that mine will not be on such bad shape inside...

I have yet some questions before jumping into my restoration project.

The first one is about grease and gears: when I'll open and remove all the old grease from my Hobart, how can I do to preserve all those metal parts from rusting? What liquid or solvent can I use to help me put all that old grease out? I've seen that you have been searching a lot about greases. Could you help me find which one buy?

The second question is about powdercoating: I've seen on Zug's photos that there is a need for some part to plug and mask before sending to the powdercoating. Is that really necessary? If yes, do someone here have photos of that process or how can I do that?

Thanks in advance for your really helpful advices!

Yes remove all the grease and use zip-lock plastic to identify everything. Unless you scrub each part with a de-greasing agent you will not remove all the grease completely from the gears. There will always be a thin film of residue on all of the parts, you should not be concerned with rust. If you still have concerns brush them with oil, which you have to remove before re-assembly. On the fresh loaf there is discussion on the grease the most common are Shell Darina #2 (this is specified in the service manual) and Mobil FM222 grease, I went with the Mobil FM222. I will be preparing an N50 for sandblasting and powder coat during the next 3 weeks, I will take pictures to show you the metal plates and bolts I used for masking during sandblasting and powder coating.

Hi Givemethedough,

Thanks very much for your answers! I've bought two Mobil FM222 foodgrease tubes (2x400g). Hope this will do!

I'm glad that you are also working on the refurbishing of another Hobart. I'll be very pleased to see your photos as you progress!

Limezy,

I have dis-assembled an N50. The attached photos show screws that I am inserting to protect from sandblasting and powder coat. I also have some plates for the transmission and motor housing. There was a small hole in the pedestal that was for grounding, I have enlarged this hole and will still a circuit breaker in its location. I will ground in a more hidden location. I will be adding other pictures before sandblasting.

Hi Givemethedough, thank you very much for your message! Could you please upload bigger files?

Hi Givemethedough,